A thermal high-pressure separation system and its processing method

A technology of thermal high-pressure separation and thermal high-pressure separator, which is applied in the fields of hydrocarbon distillation and petroleum industry, etc. It can solve the problems of cumbersome and complicated process and difficult to achieve gas phase desolidification effect, achieve simple operation, solve tank top gas phase desolidification, reduce Effect of Solids Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

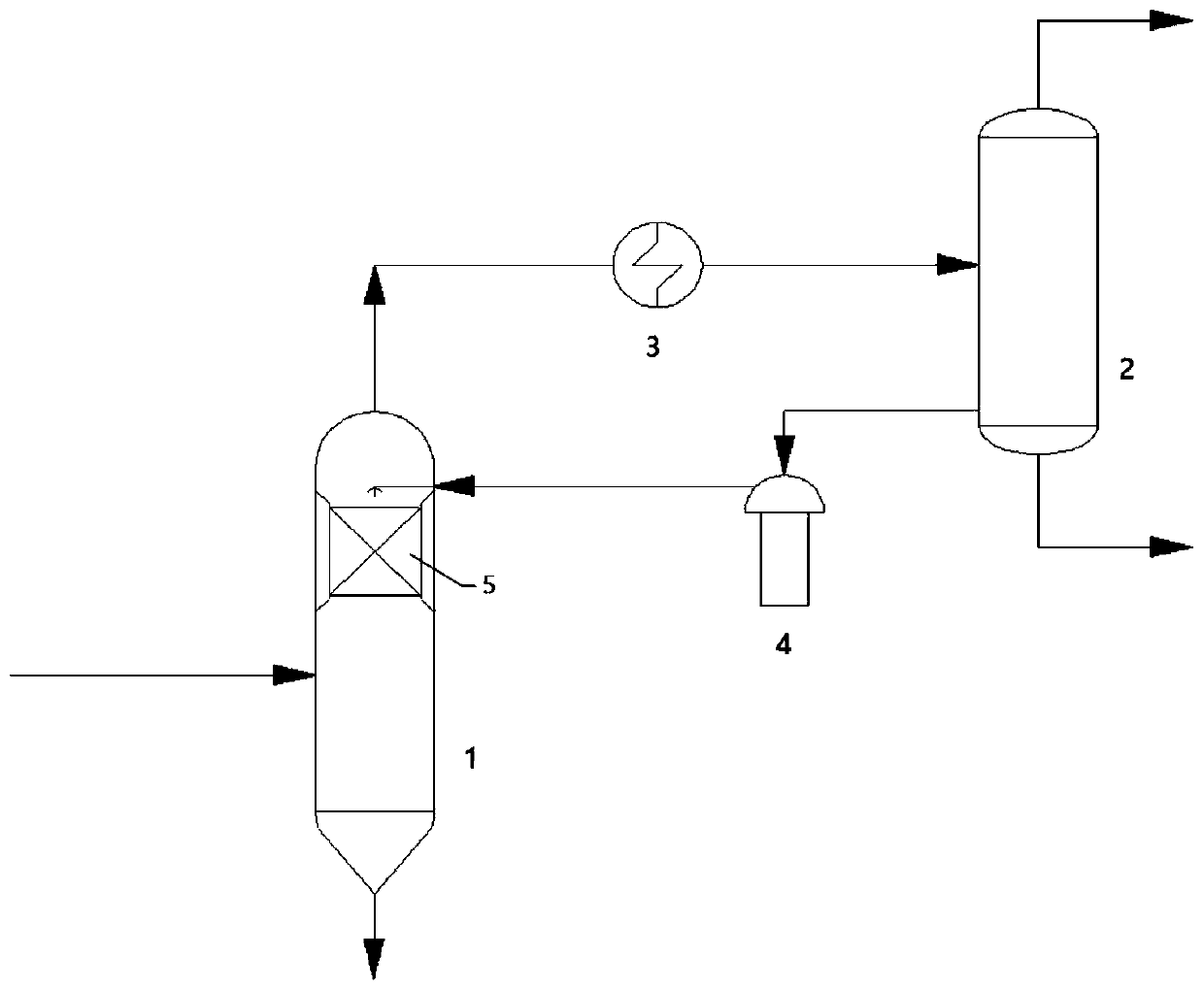

[0048] This embodiment provides a thermal high-pressure separation system and its processing method, such as figure 1 As shown, the system includes a hot high-pressure separator 1 , a warm and high-pressure separator 2 , a heat exchanger 3 , a power transmission device 4 and a packing section 5 .

[0049] Wherein, a packing section 5 is provided above the middle section of the hot high-pressure separator 1, and a washing oil inlet is arranged above the packing section 5. The feed inlets are connected by a pipeline, and a heat exchanger 3 is arranged on the pipeline, and the heat exchanger 3 is a high-pressure heat exchanger. The side line of the hot high-pressure separator 1 is provided with a material inlet connected to a feed pipeline of the suspension bed hydrogenation reaction product. The produced oil of the warm and high pressure separator 2 is divided into two parts, the first part is extracted from the nozzle at the bottom of the side line of the warm and high pressur...

Embodiment 2

[0058] This embodiment provides a thermal high-pressure separation system and its processing method. The thermal high-pressure separation system used in this embodiment is the same as that in Embodiment 1.

[0059] The method for processing by the above system comprises the following steps:

[0060] (1) adding the suspension bed hydrogenation reaction product to the hot high-pressure separator 1 for separation;

[0061] (2) The 300°C tank top gas phase produced by the hot and high-pressure separator 1 is cooled to 200°C by the heat exchanger 3 and then enters the warm and high-pressure separator 2 for separation, and the tank bottom oil produced by the hot and high-pressure separator 1 is sent to the subsequent device;

[0062] (3) The tank top gas phase produced by the temperature and high pressure separator 2 is sent to the follow-up device, and the temperature of the oil produced by the temperature and high pressure separator 2 is 200°C. The produced oil is divided into t...

Embodiment 3

[0065] This embodiment provides a thermal high-pressure separation system and its processing method. The thermal high-pressure separation system used in this embodiment is the same as that in Embodiment 1.

[0066] The method for processing by the above system comprises the following steps:

[0067] (1) adding the suspension bed hydrogenation reaction product to the hot high-pressure separator 1 for separation;

[0068] (2) The 450°C tank top gas phase produced by the hot and high-pressure separator 1 is cooled to 300°C by the heat exchanger 3 and then enters the warm and high-pressure separator 2 for separation, and the tank bottom oil produced by the hot and high-pressure separator 1 is sent to the subsequent device;

[0069] (3) The tank top gas phase produced by the high-temperature and high-pressure separator 2 is sent to the subsequent device, and the temperature of the oil produced by the high-temperature and high-pressure separator 2 is 300°C. The produced oil is div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com