Novel straw water washing device

A water washer and straw technology, which is applied in the direction of digesters, chemical instruments and methods, textiles and papermaking, etc., can solve the problems affecting the quality of raw material hydrolysis into pulp, the service life reliability of chemicals and steam consumption equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

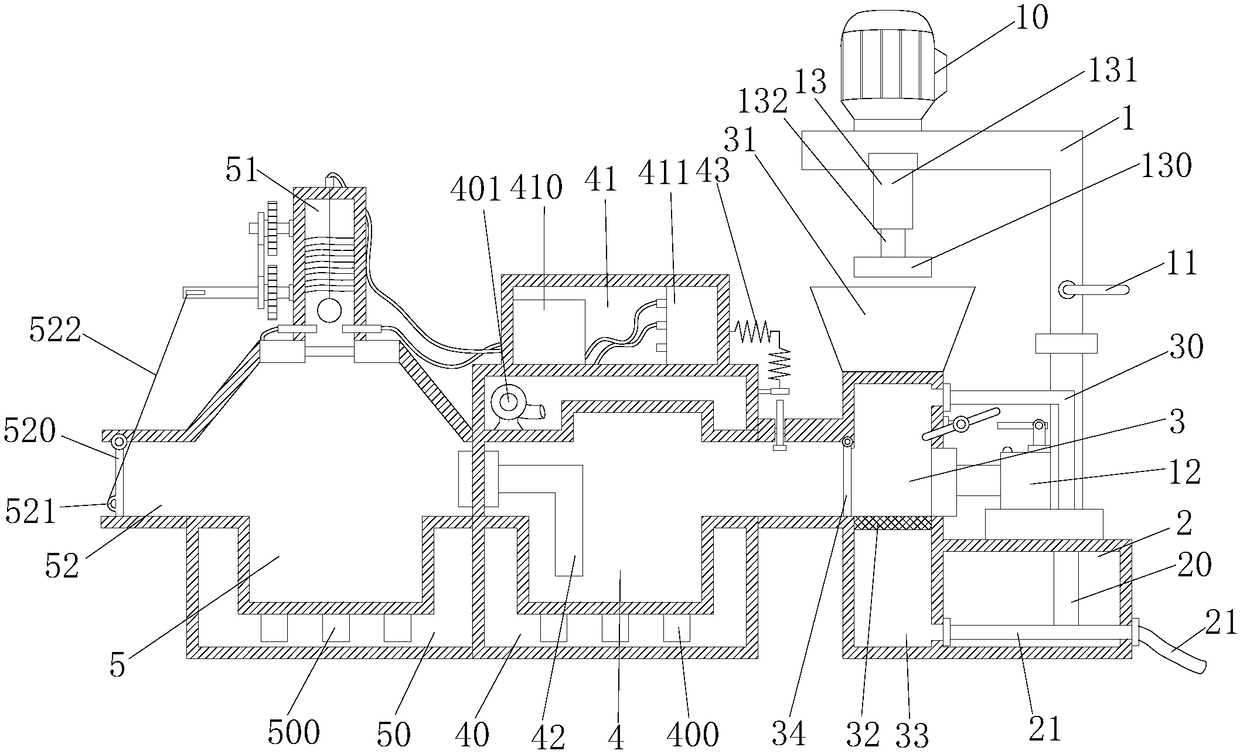

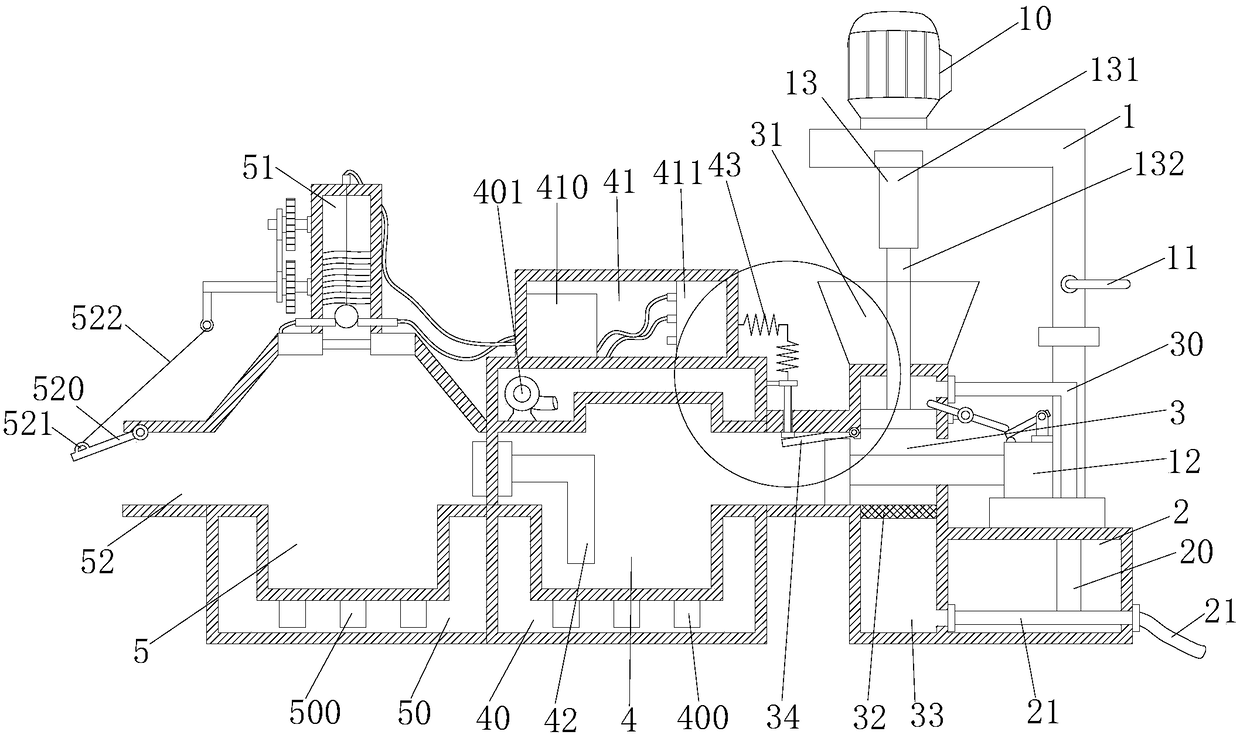

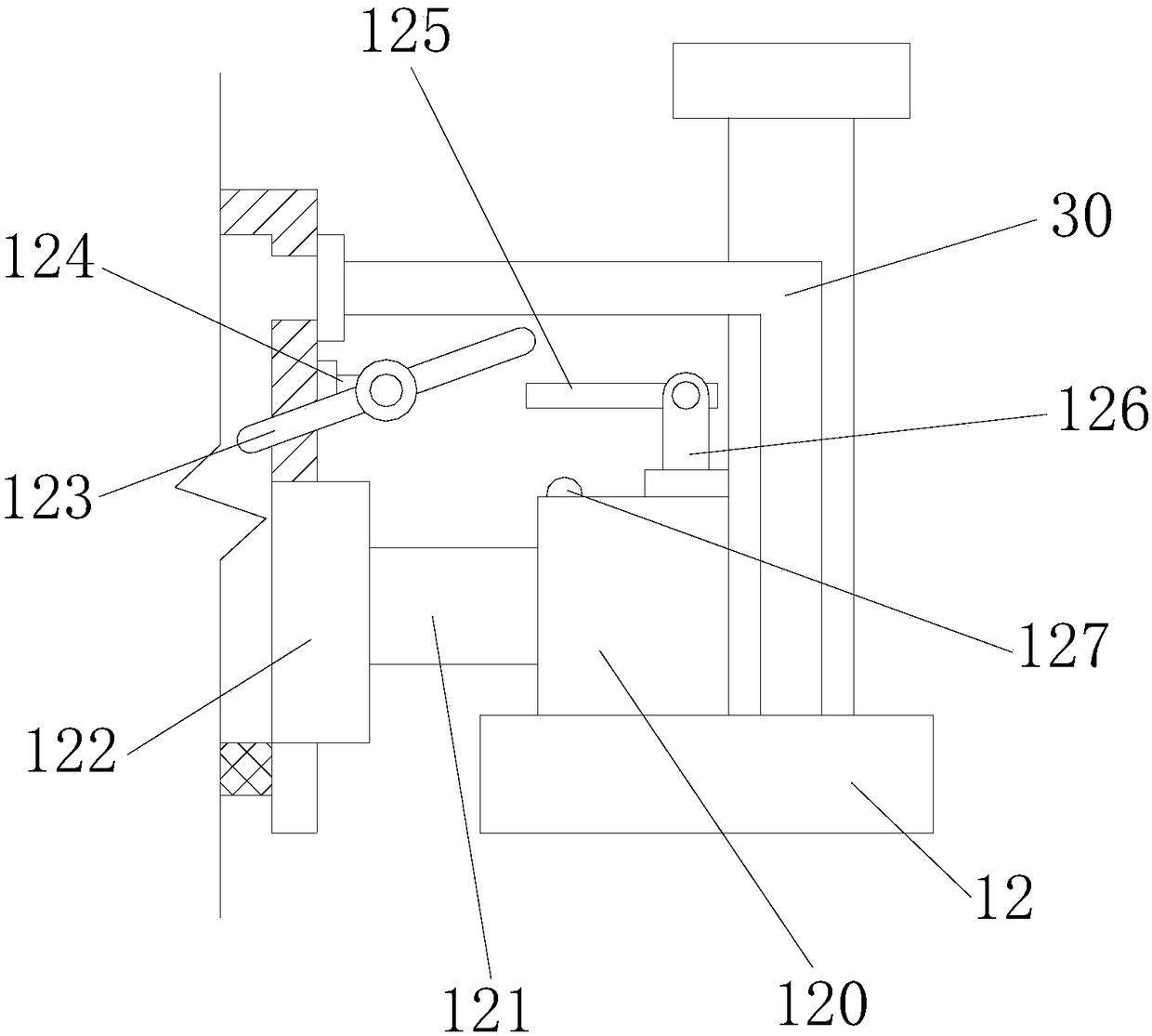

[0029] see Figure 1-Figure 8 , the present invention provides a new type of straw water washer technical solution: its structure includes an external transmission bracket 1, a bottom reserved water tank 2, a straw cleaning and dehydration box 3, a straw cooking box 4, and a heating and hydrolysis box 5. The external transmission bracket 1 passes through The bolts are riveted and connected above the bottom reserved water tank 2, and the bottom reserved water tank 2 is vertically welded to the side of the straw cleaning and dehydration tank 3, and the straw cleaning and dehydration tank 3 is vertically welded to the straw cooking tank 4 and the bottom reserved water tank 2 Between, the straw cooking box 4 is vertically welded between the straw clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com