Repairable multistage energy dissipation dry-type mixed fabricated type concrete shear wall

A concrete shear wall, dry mixing technology, applied in the direction of walls, protective buildings/shelters, building components, etc., can solve problems such as restricting the development of prefabricated concrete shear wall structures and failing to give full play to precast concrete technology. , to achieve the effect of achieving repairability, improving anti-instability ability, and obvious technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

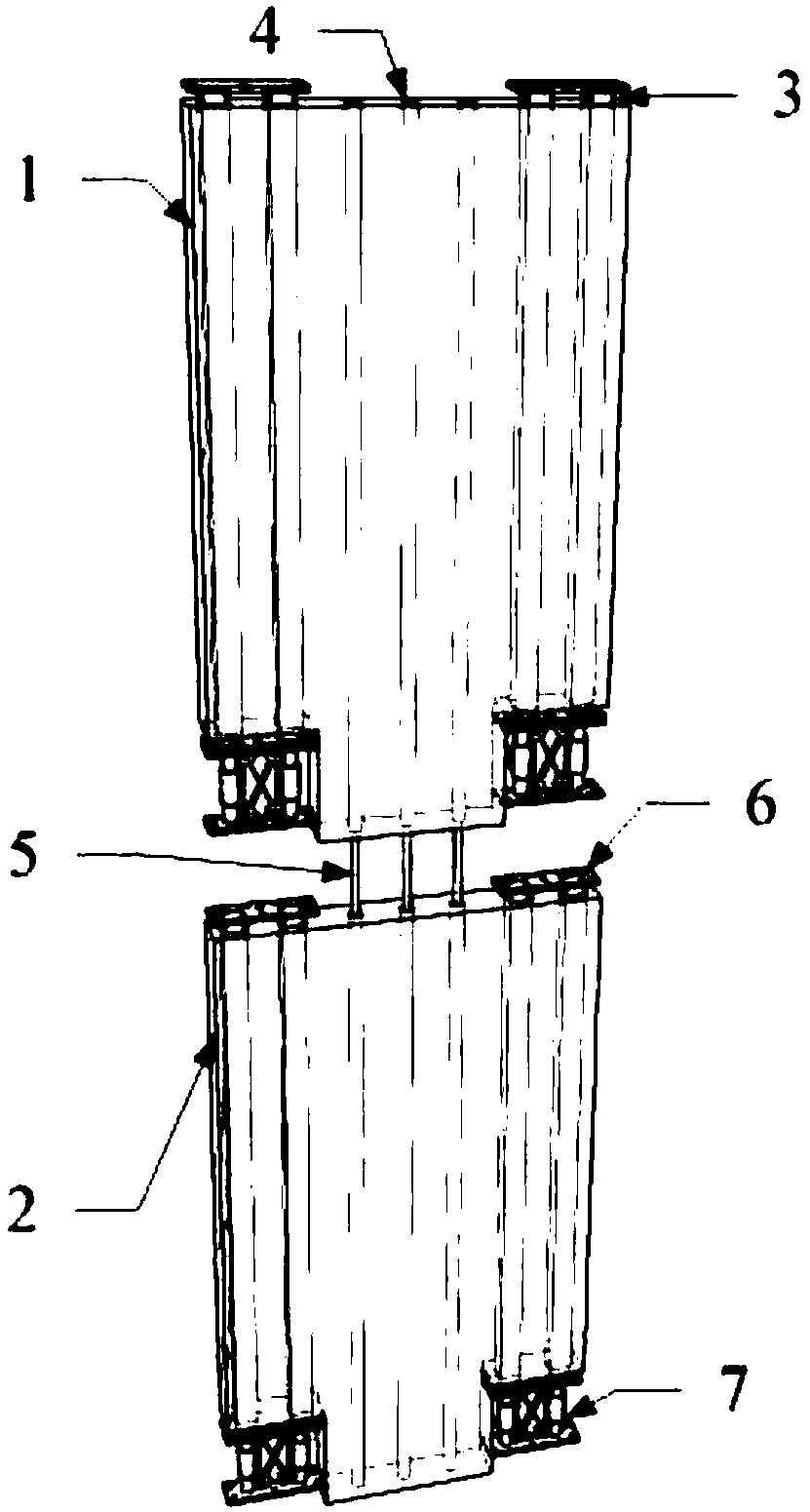

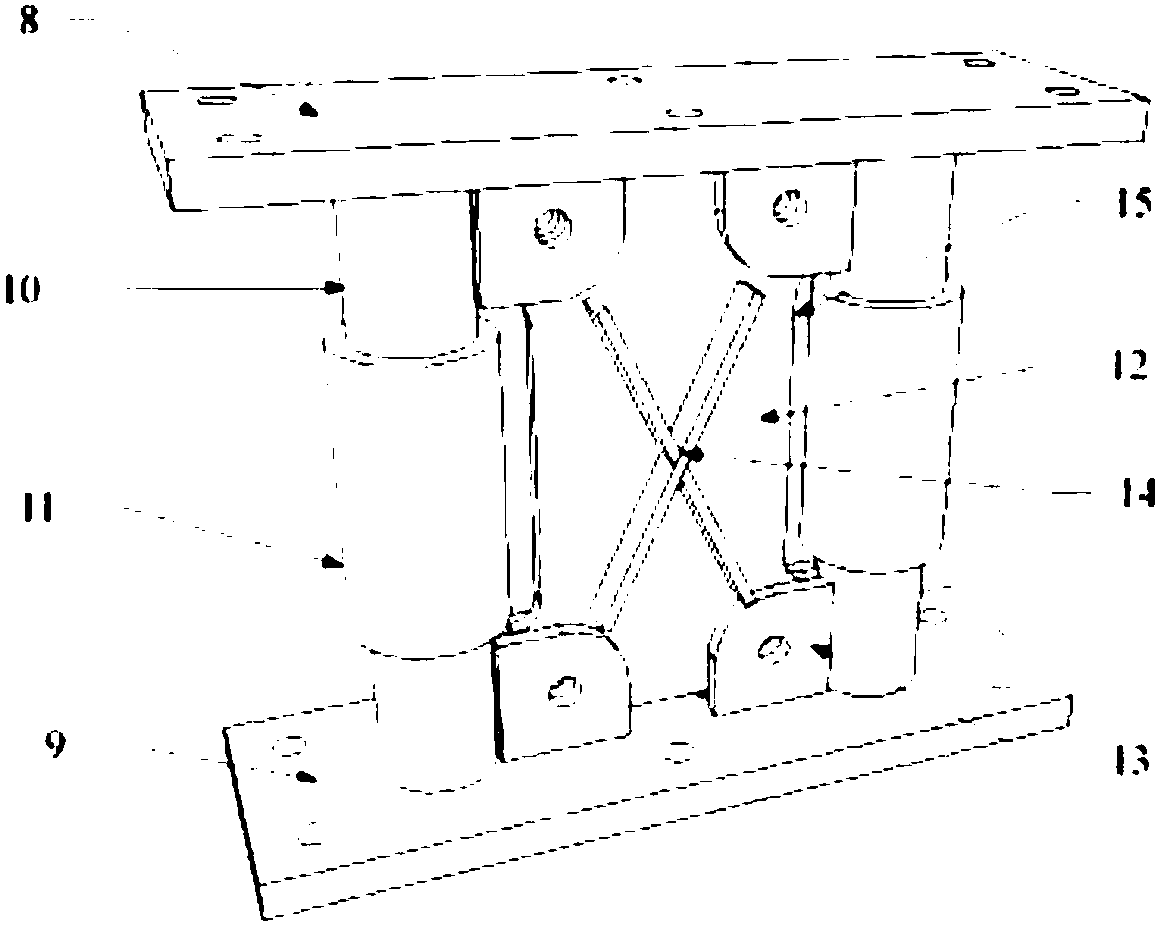

[0015] Such as figure 1 with 2 Shown: a repairable multi-stage energy-consuming dry mixed prefabricated concrete shear wall, including the upper precast concrete shear wall 1, the lower precast concrete shear wall 2, the pre-embedded high-strength steel pipe 3, the middle pre-embedded steel pipe 4, Prestressed threaded steel bars 5, end plates 6 and multi-stage energy-consuming parts;

[0016] The upper precast concrete shear wall 1 and the lower precast concrete shear wall 2 are respectively equipped with pre-embedded high-strength steel pipes 3, and the pre-embedded high-strength steel pipes 3 are filled with high-strength concrete. The upper precast concrete shear wall 1 and the lower precast concrete The interior of the shear wall 2 is also provided with a through middle pre-embedded steel pipe 4, and the pre-stressed threaded steel bar 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com