Prestress wire whole bundle pulling device and construction method for pulling prestress wire harness whole body

A technology of prestressed steel strand and traction device, which is applied to the construction of the overall traction of prestressed steel strand bundles, and the field of prestressed steel strand whole bundle traction device, can solve the problem of reduced hole diameter, difficulty of steel strand bundles, and prestressed Problems such as the difficulty of threading the stress steel strand bundle to achieve the effects of reliable connection, high construction efficiency, high economy and practical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An integral traction device for prestressed steel strand bundles:

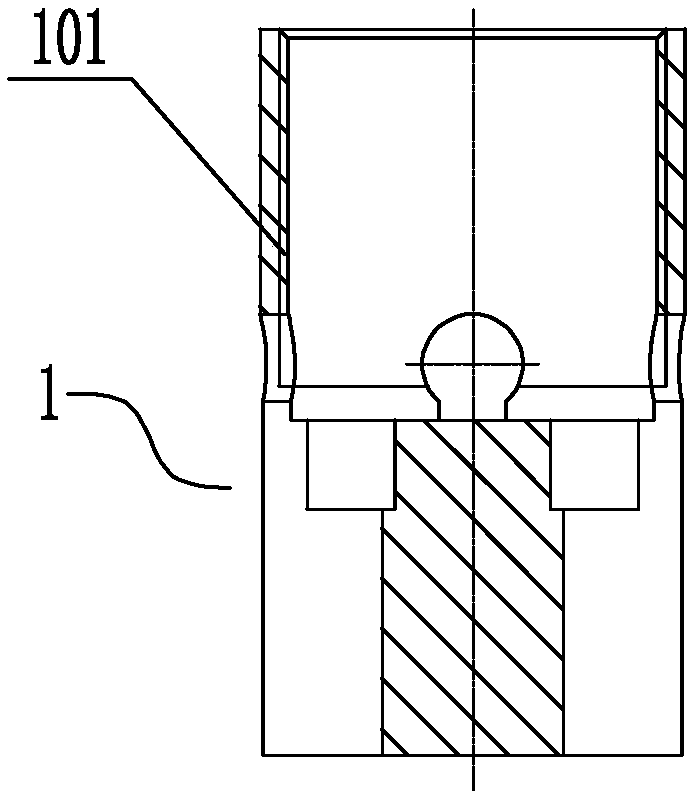

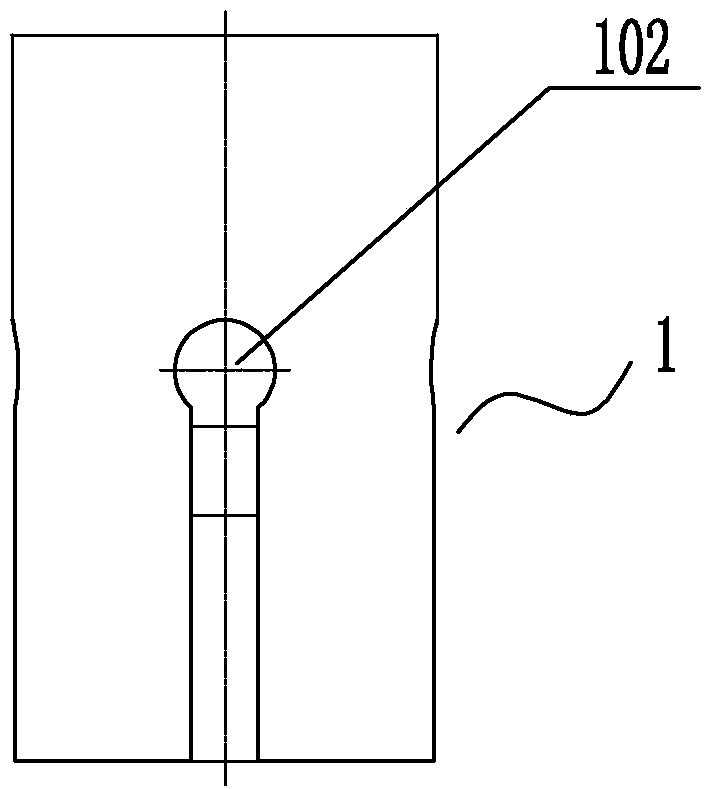

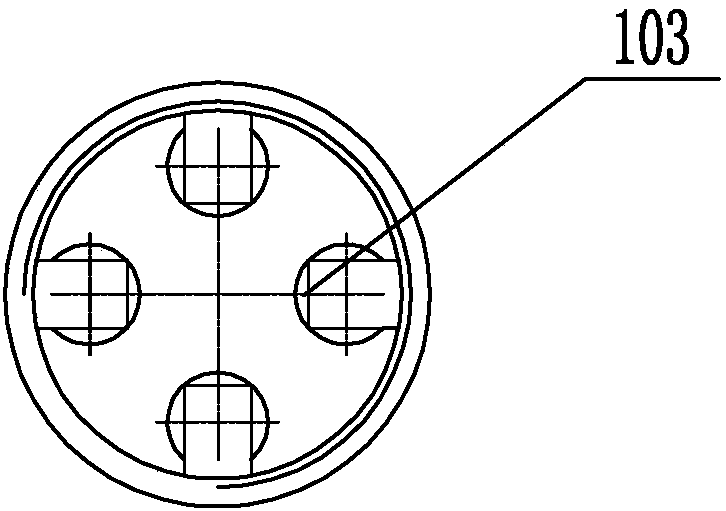

[0038] Such as Figure 8 As shown, the overall traction device of the prestressed steel strand bundle includes a positioning seat 1 and a traction head 2; the positioning seat 1 is a cylindrical member, and the outer diameter of the cylindrical member is equal to the diameter of the smallest circumscribed circle of the steel strand bundle Or slightly smaller, one end of the cylindrical member is a threaded section 101 with an internal thread, and the side of the other end of the cylindrical member is evenly distributed with 4 grooves 102 for the center wire of one end to pass through, and the top of the groove 102 Connect a circular counterbore 103 larger in diameter than the groove 102 (see Figure 1-Figure 3 , Figure 8 );

[0039] One end of the pulling head 2 is a cylindrical section 202 with an external thread, and the other end is a joint 201 for connecting with a rotary connector, the maximum ...

Embodiment 2

[0042] A construction method for integral traction of prestressed steel strand bundles:

[0043] It adopts the prestressed steel strand integrated traction device described in the first embodiment to realize the construction method of the prestressed steel strand integrated traction, and it includes the following steps:

[0044] A. Pretreatment of prestressed steel strand bundles:

[0045] Strip the front end of each steel strand 3 of the pre-loaded steel strand bundle and cut off a certain length, leaving the center wire 302, and heading the center wire. The processed steel strands refer to Figure 6 ;

[0046] B. Install the overall traction device of the prestressed steel strand harness (see Figure 7 , Figure 9 , Figure 10 ):

[0047] B1. Install the steel strands of the prestressed steel strand bundles that have been upset through the grooves 102 of the positioning seat 1 and install them at the predetermined positions of the positioning seat, and the pier head 303...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com