Visual temperature and pressure resistance device, gas-liquid interface mass transfer dissolution measurement device and method

A technology of gas-liquid interface and measurement method, which is applied in the field of gas-liquid interface mass transfer dissolution measurement device, visual temperature and pressure resistance device, and can solve the real state error of oil reservoir, and there is no oil-gas interface mass transfer dissolution evaluation method and evaluation. system, affecting the final result, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

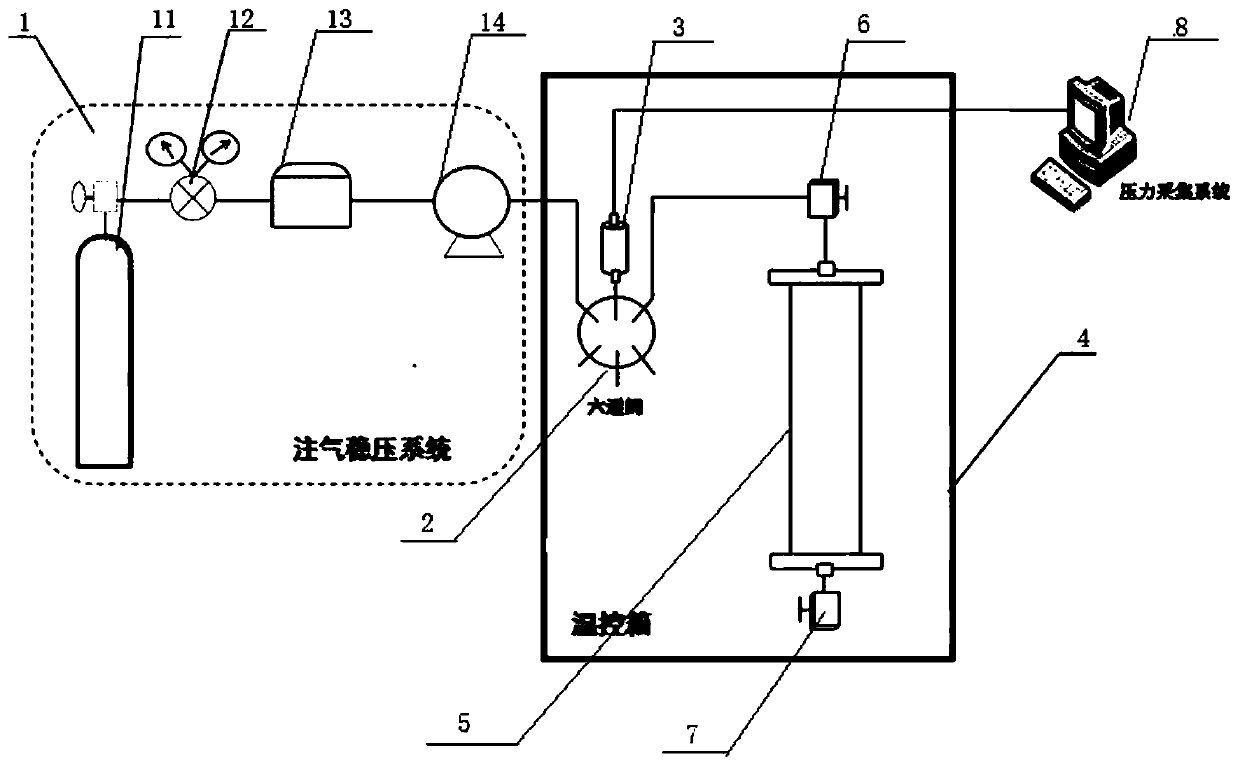

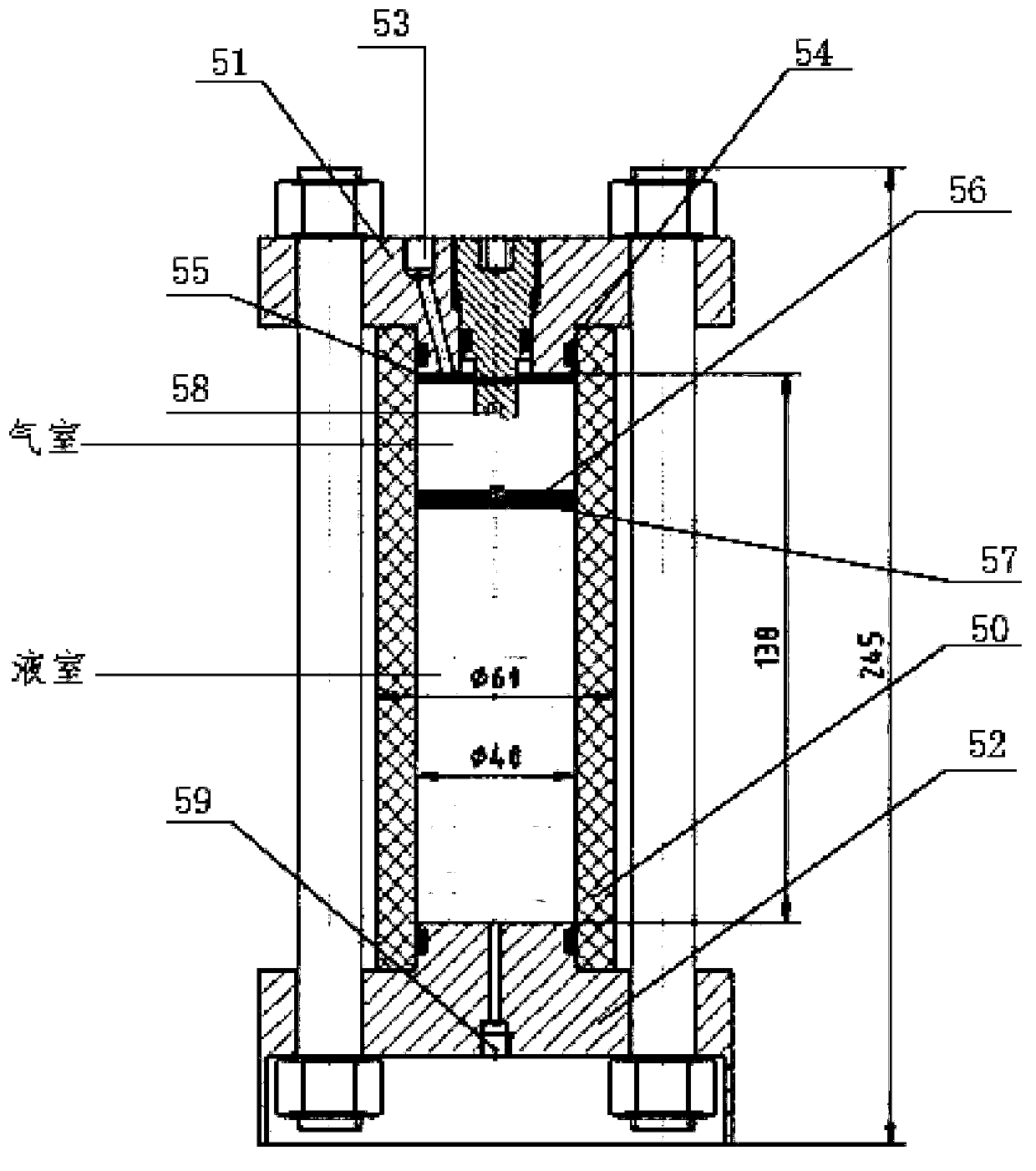

[0051] This embodiment provides a gas-liquid interface mass transfer dissolution measurement device, such as figure 1 As shown, the device includes a voltage stabilizing system 1, a six-way valve 2, a pressure sensor 3, a temperature control box 4, a visible temperature and pressure resistance device 5, a first leak-proof switch 6, a second leak-proof switch 7 and a master station computer8. Wherein, the voltage stabilizing system 1 includes a high-pressure gas tank 11, a pressure reducing valve 12, a flow controller 13, a voltage stabilizer 14, and the high-pressure gas tank 11 is equipped with detection gas, and the components in the voltage stabilizing system are connected by stainless steel pipelines, namely The pressure reducing valve 12 is arranged at the outlet of the high-pressure gas tank 11. After the pressure reducer 12, the pipeline is connected to the flow controller 13 and the voltage regulator 14 in sequence; Pressure sensor 3 and the first anti-leakage switch ...

Embodiment 2

[0056] In this embodiment, the gas-liquid interface mass transfer and dissolution measurement device of Embodiment 1 is used to conduct an indoor oil-gas interface mass transfer movement simulation experiment, in which the first leak-proof switch 6 and the second leak-proof switch 7 in the device are both ball valves. The steps of the simulation experiment are as follows:

[0057] (1) Open the first anti-leakage switch 6 and the second anti-leakage switch 7, inject gas into the gas injection hole 53, and empty the liquid in the transparent measurement observation chamber 50, so that the semi-permeable piston 56 is positioned at the bottom of the transparent measurement observation chamber 50 Then the vacuum pump is connected with the first leak-proof switch 6, the first leak-proof switch 6 is opened, the second leak-proof switch 7 is closed, the vacuum pump is started, and the transparent measurement and observation chamber 50 is vacuumized to the laser displacement sensor 57 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com