Closed electrolytic cell

An electrolytic cell and plexiglass technology, applied in the field of electrolysis, can solve problems such as inconvenient transportation and heavy weight of the electrolytic cell, and achieve the effects of preventing collection, small footprint, and reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

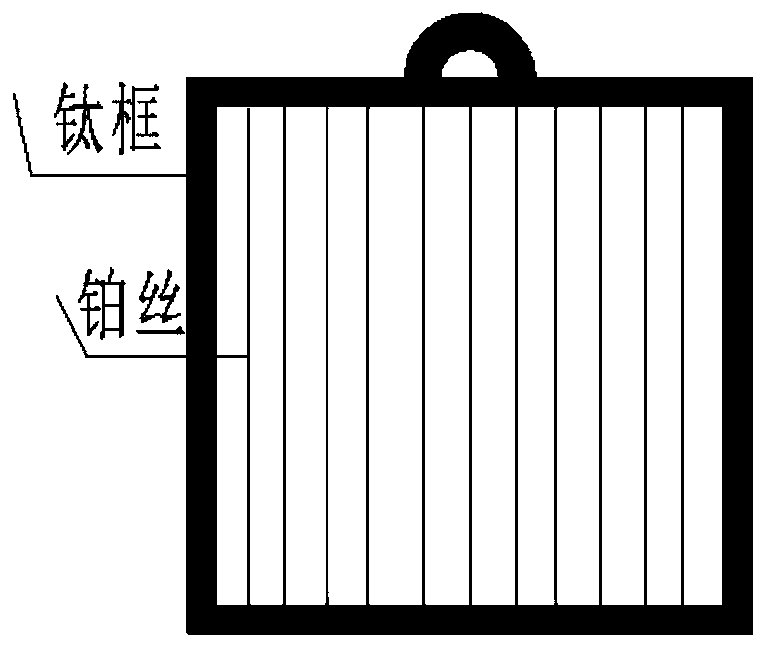

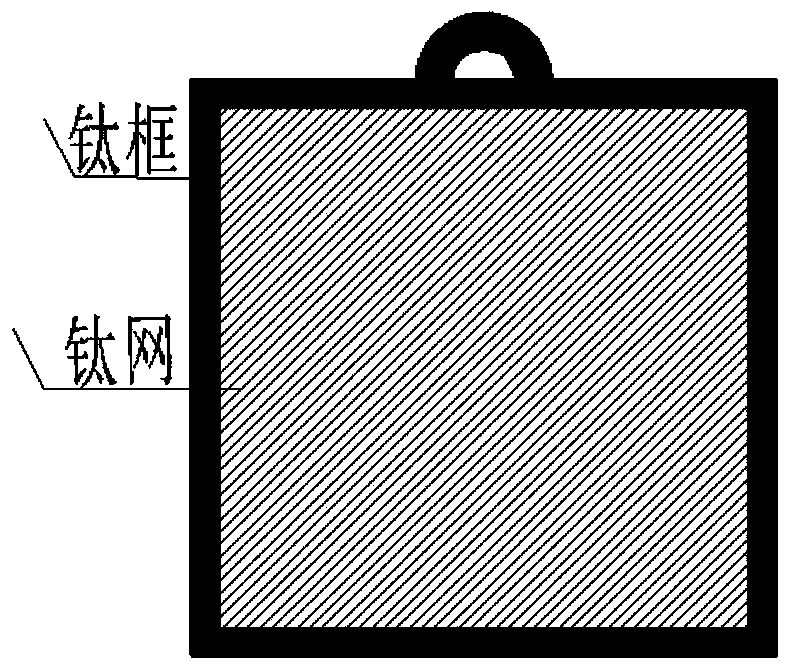

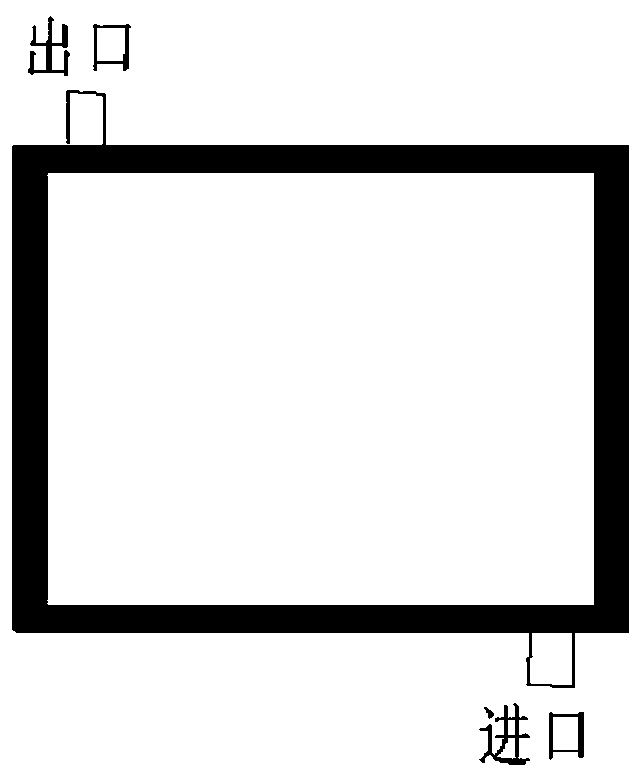

[0035] figure 1 It is the structural representation of embodiment 1 anode plate; figure 2 It is the structural representation of embodiment 1 cathode plate; image 3 It is the structural representation of embodiment 1 plexiglass frame; Figure 4 It is a structural schematic diagram of the side plate of Embodiment 1.

[0036] The electrolysis of ammonium sulfate to generate ammonium persulfate is taken as an example for illustration. according to Figure 5 Install the electrolyzer in the manner shown, where 1, 3 and 5 are anolyte inlets, 2 and 4 are catholyte inlets, 6, 8 and 10 are anolyte outlets, 7 and 9 are catholyte outlets, and 3 anode chamber units are installed , 2 cathode chamber units form 3 electrolytic units. The anolyte is 490g / L ammonium sulfate solution, the catholyte is a mixture of 490g / L ammonium sulfate solution and 2mol / L sulfuric acid, the ion exchange membrane is used as the diaphragm, the thickness of the plexiglass frame is 5cm, the anode plate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com