Full-sealed battery case used for nano silicon-magnesium solid battery

A solid-state battery, fully sealed technology, used in small-sized batteries/batteries, large-sized batteries/batteries, battery boxes/jackets, etc., can solve electrolyte pollution, poor sealing performance, and insufficient isolation of electrolytes from the external environment. and other problems, to achieve the effect of stacking stability, improving adaptability and sealing, and achieving large-scale splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described below in conjunction with specific embodiments.

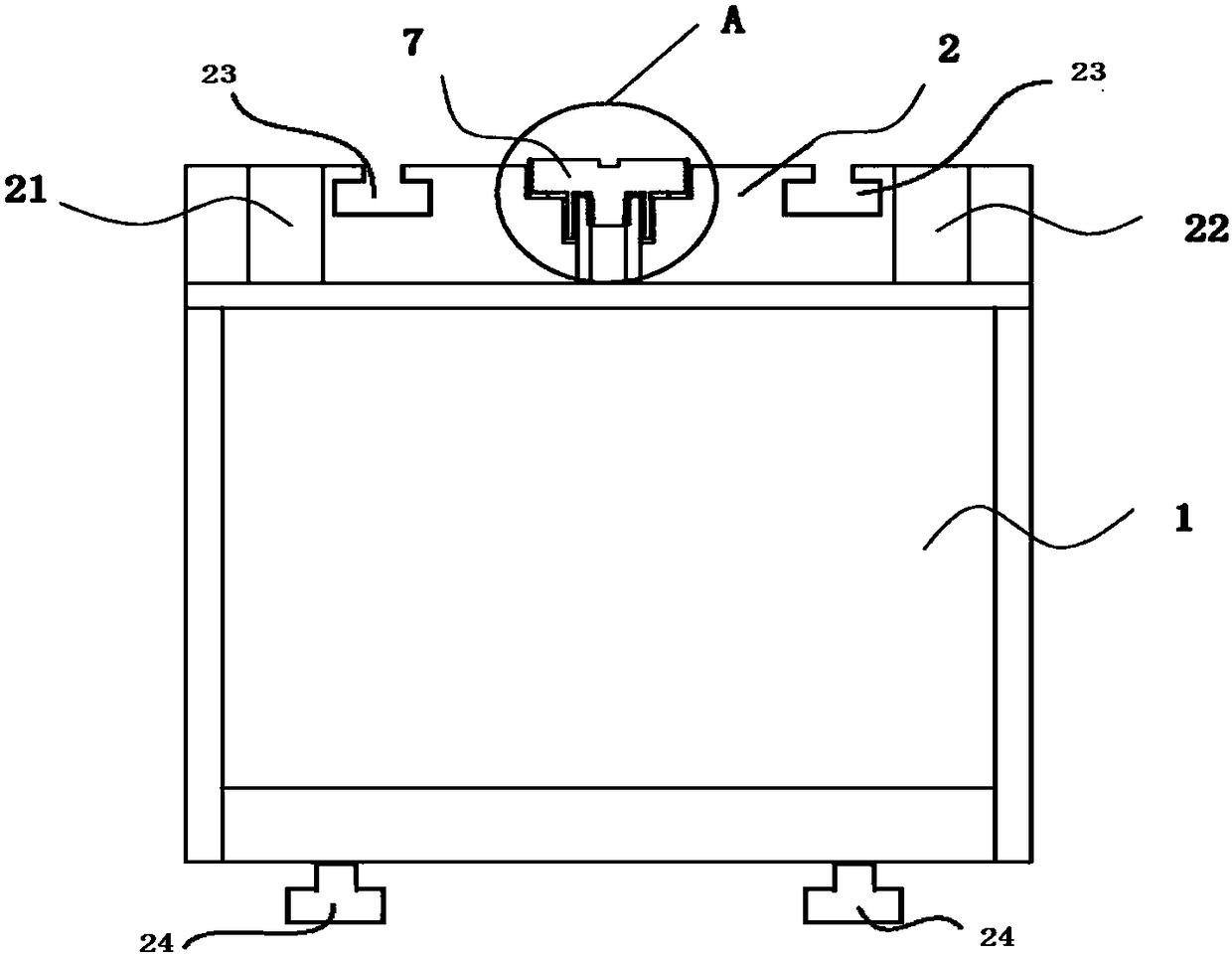

[0017] see reference figure 1 and figure 2 , a fully sealed battery case for nano-silicon-magnesium solid-state batteries, including a case body 1, and an upper cover 2 arranged on the case body 1, the left and right ends of the upper cover 2 are respectively provided with positive electrode installation holes 21 and negative electrode installation hole 22; the two sides of the upper end surface of the cover are respectively provided with convex card slots, the convex card slots 23 longitudinally penetrate the two sides of the upper cover 2, and the lower end surface of the box body is longitudinally arranged There is a protrusion 24 adapted to the size of the convex card slot 23;

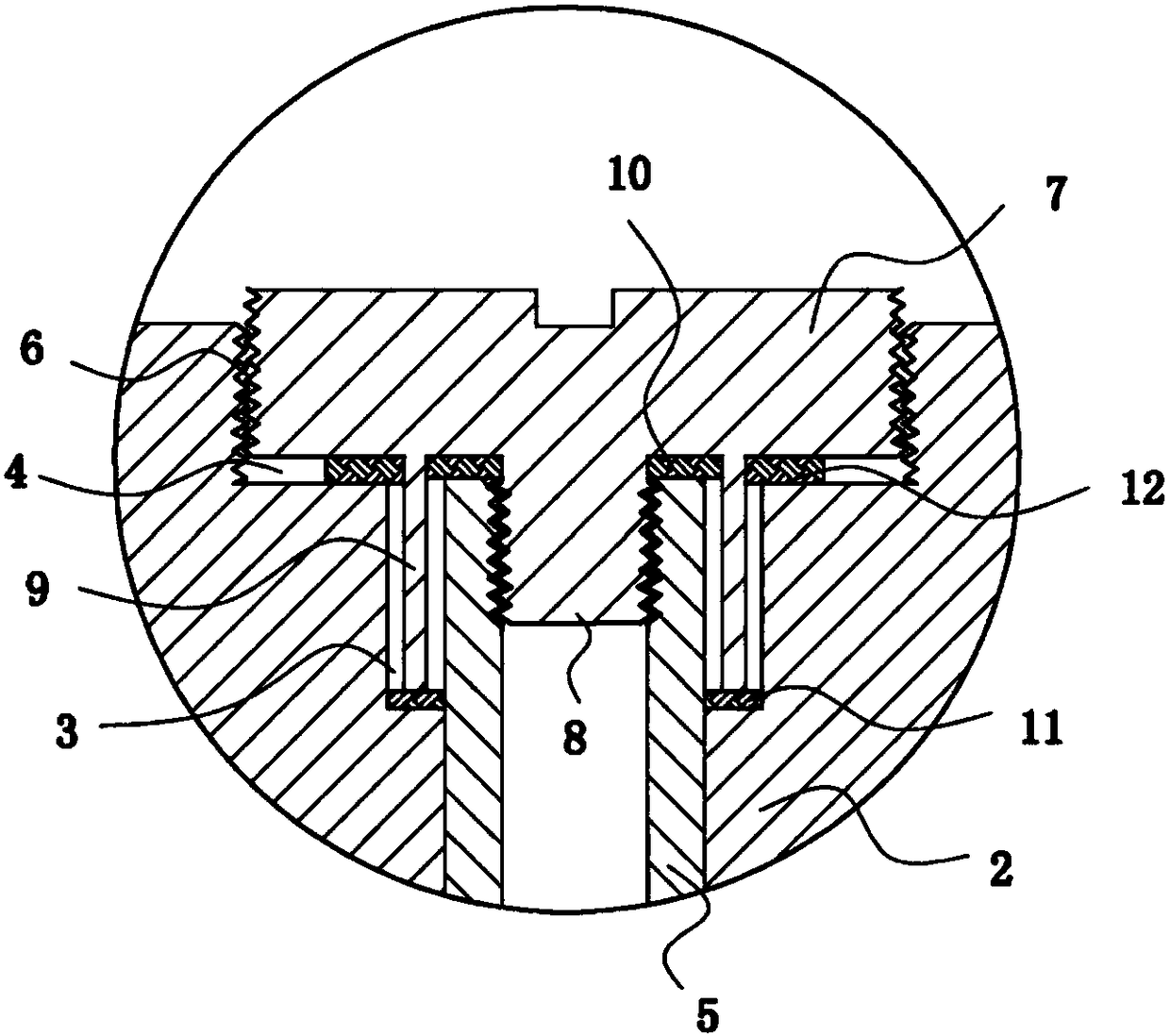

[0018] The middle part of loam cake 2 is provided with groove 3 and groove 4 (first groove and second groove), and described groove 3 and groove 4 are coaxially arranged and the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com