Intelligent inspection system for high-voltage cable

A technology of intelligent patrol inspection and high-voltage cables, which is applied to overhead line/cable equipment, fault detection according to conductor type, fault location, etc., can solve the problems of poor stability of helicopter patrol inspection and time-consuming and laborious manual inspection, and achieve improvement Safety and stability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] When cracks appear on high voltage cables, such as Figure 6 shown, perform the following steps:

[0067] S11, data acquisition: the data acquisition module 32 arranged on the intelligent inspection robot 3 collects the real-time status data of the high-voltage cable in real time, and transmits the real-time status data to the data processing module 34;

[0068] S12, data processing: the data processing module 34 compares the real-time state data with the standard data transmitted by the memory module 36, and generates a comparison result and sends it to the main control module 35;

[0069] S13, early warning judgment: the main control module 35 performs early warning processing on the comparison result, when the size and shape of the crack exceed the early warning threshold, generate early warning information and enter step S14, and when the size and shape of the crack do not exceed the early warning threshold, enter step S17;

[0070] S14, alarm judgment: the main co...

Embodiment 2

[0075] When the surface temperature of the high-voltage cable is abnormally high, such as Figure 7 shown, perform the following steps:

[0076] S21, data acquisition: the data acquisition module 32 arranged on the intelligent inspection robot 3 collects the surface temperature data of the high-voltage cable in real time and transmits the data processing module 3;

[0077] S22, data processing: the data processing module 34 compares the high-voltage cable surface temperature data with the standard temperature transmitted by the memory module 36, and generates a comparison result and sends it to the main control module 35;

[0078] S23, early warning judgment: the main control module 35 performs early warning processing on the comparison result, when the surface temperature of the high voltage cable exceeds the early warning threshold, generates early warning information and enters step S24, and when the surface temperature of the high voltage cable does not exceed the early wa...

Embodiment 3

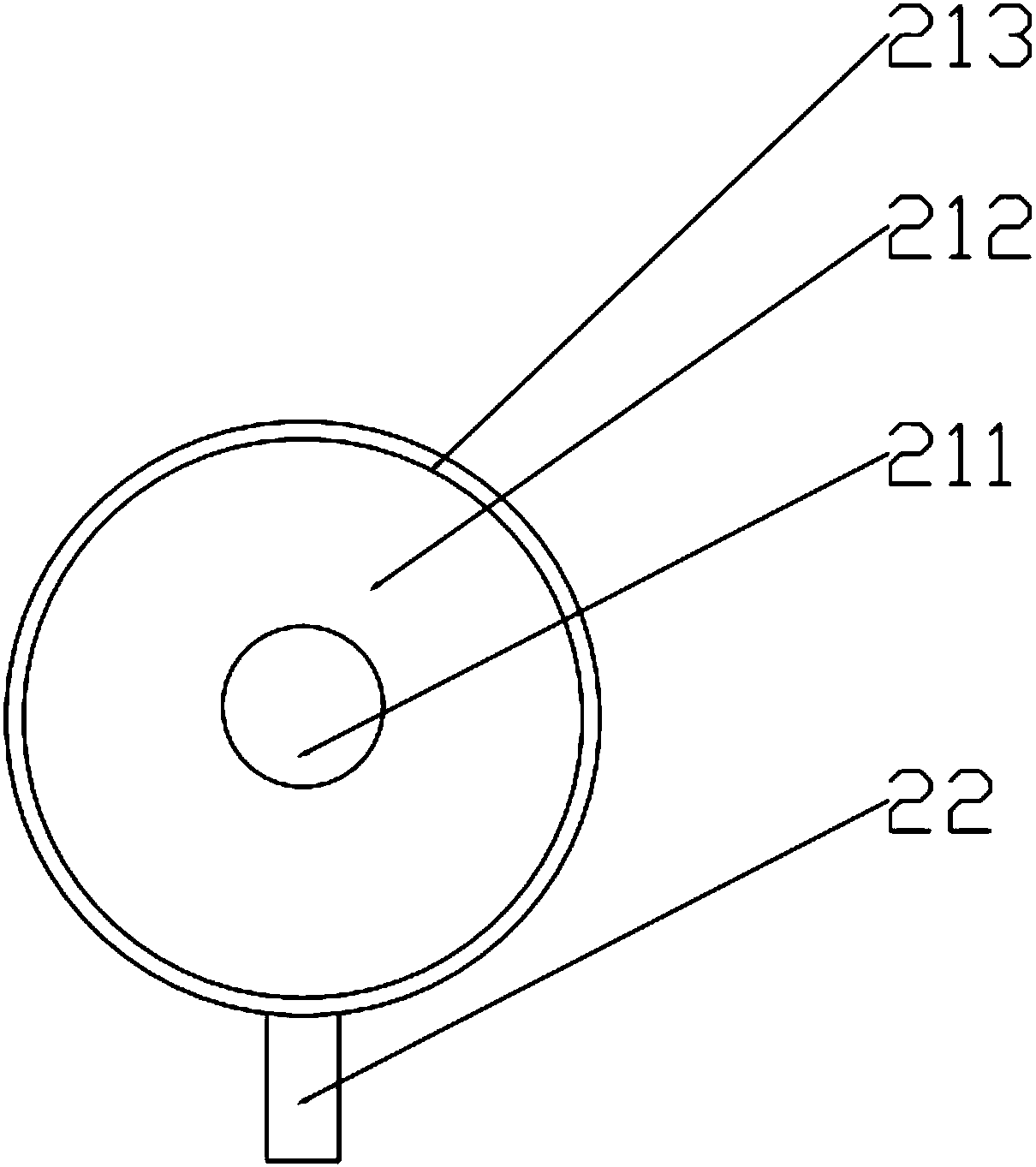

[0084] Compared with Embodiment 1, this embodiment has a different rail structure, such as Figure 8 As shown, the cross section of the guide rail body 21 is circular, including a support layer 211, an elastic material layer 212 and a wear-resistant layer 213 arranged sequentially from the inside to the outside. Same guide groove.

[0085] The concave guide groove can effectively avoid snow covering the guide device 22, so that the intelligent inspection robot 3 can better run along the extension direction of the guide device 22 on the flexible guide rail 2, and improve the stability of the intelligent inspection system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com