Electric mower and work method thereof

A lawn mower, electric technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of large vibration, high cost, air pollution and other problems of lawn mowers, and achieve the reduction of unit volume weight and maintenance costs, Improved control accuracy, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution, and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

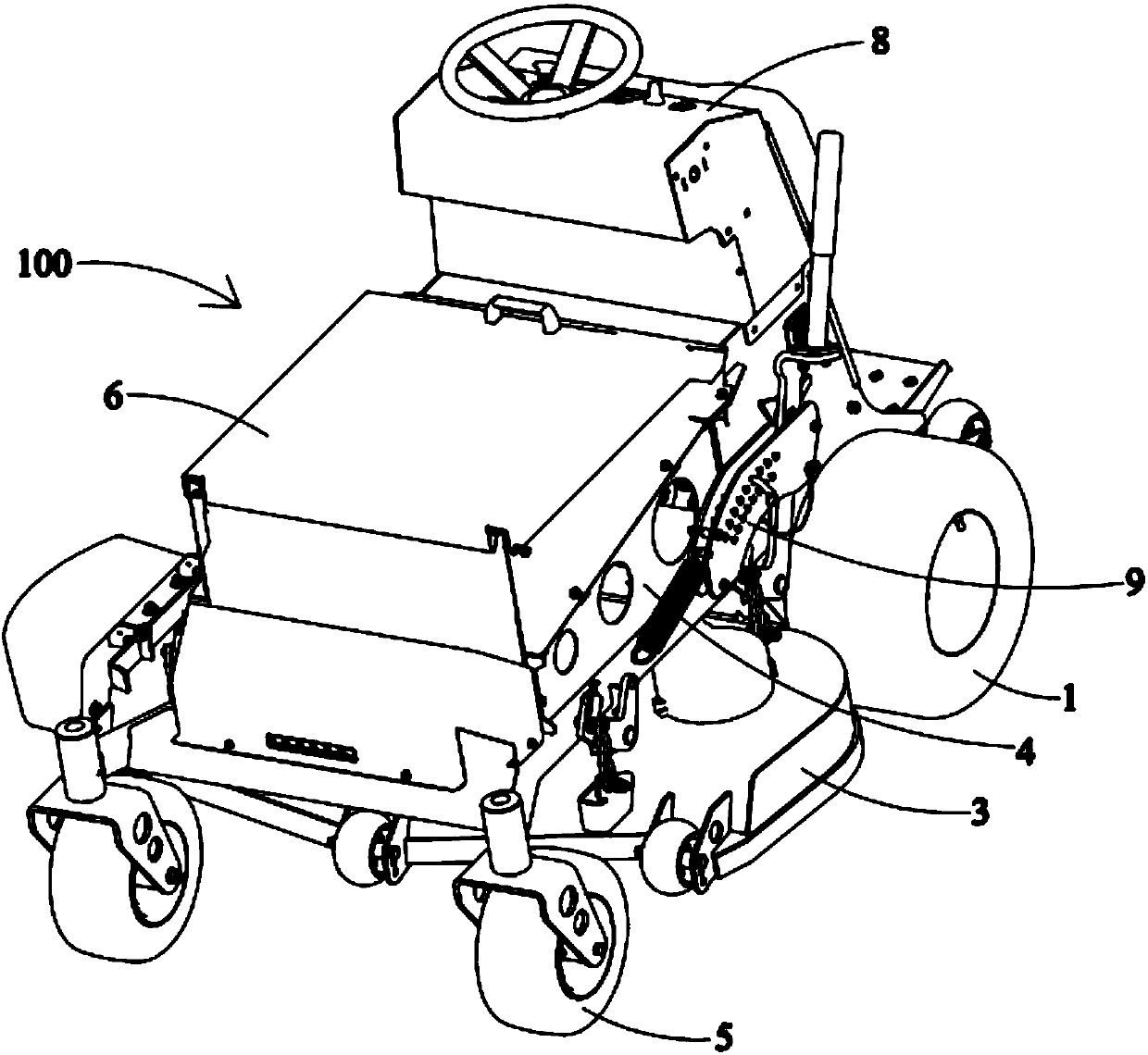

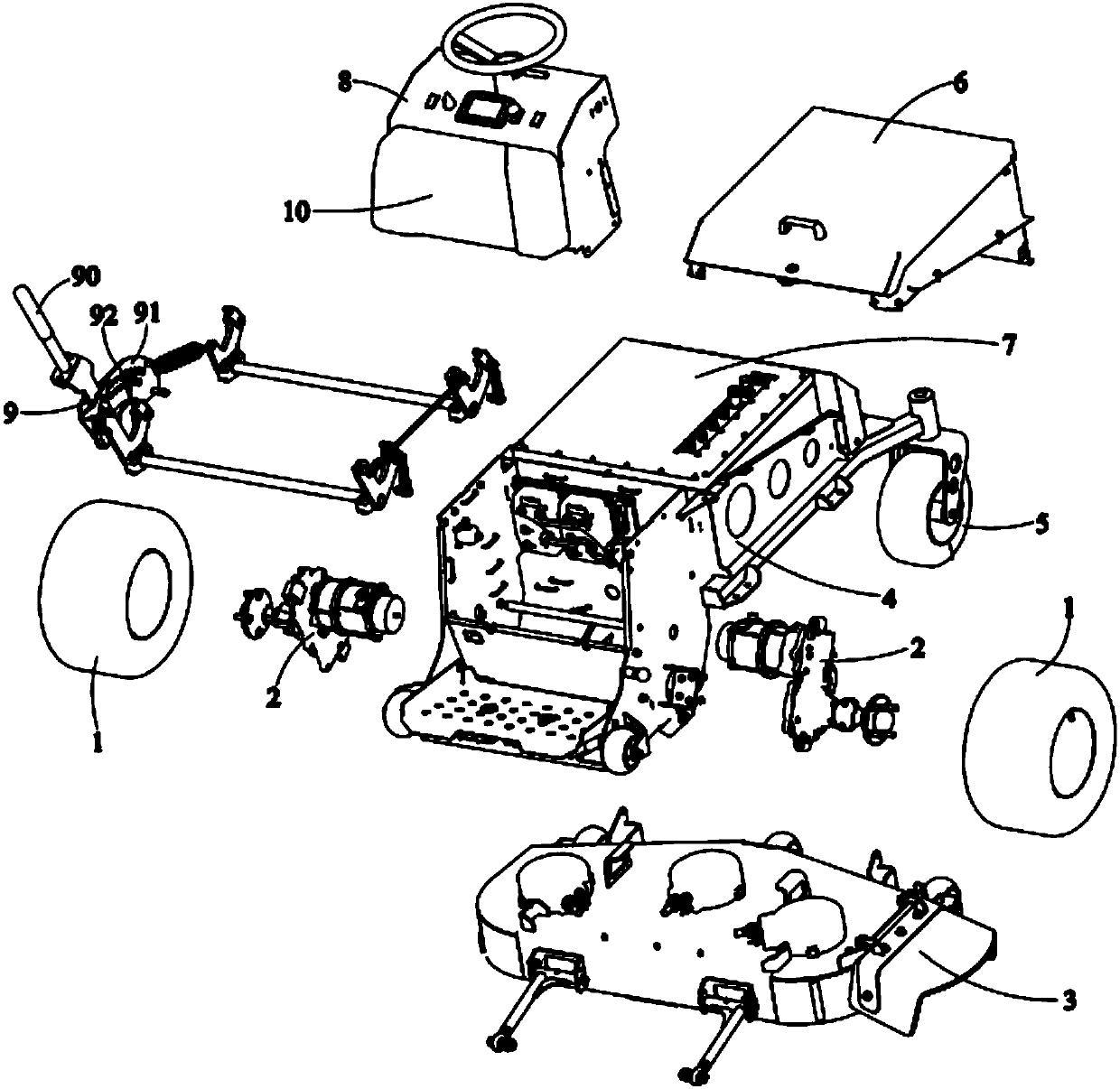

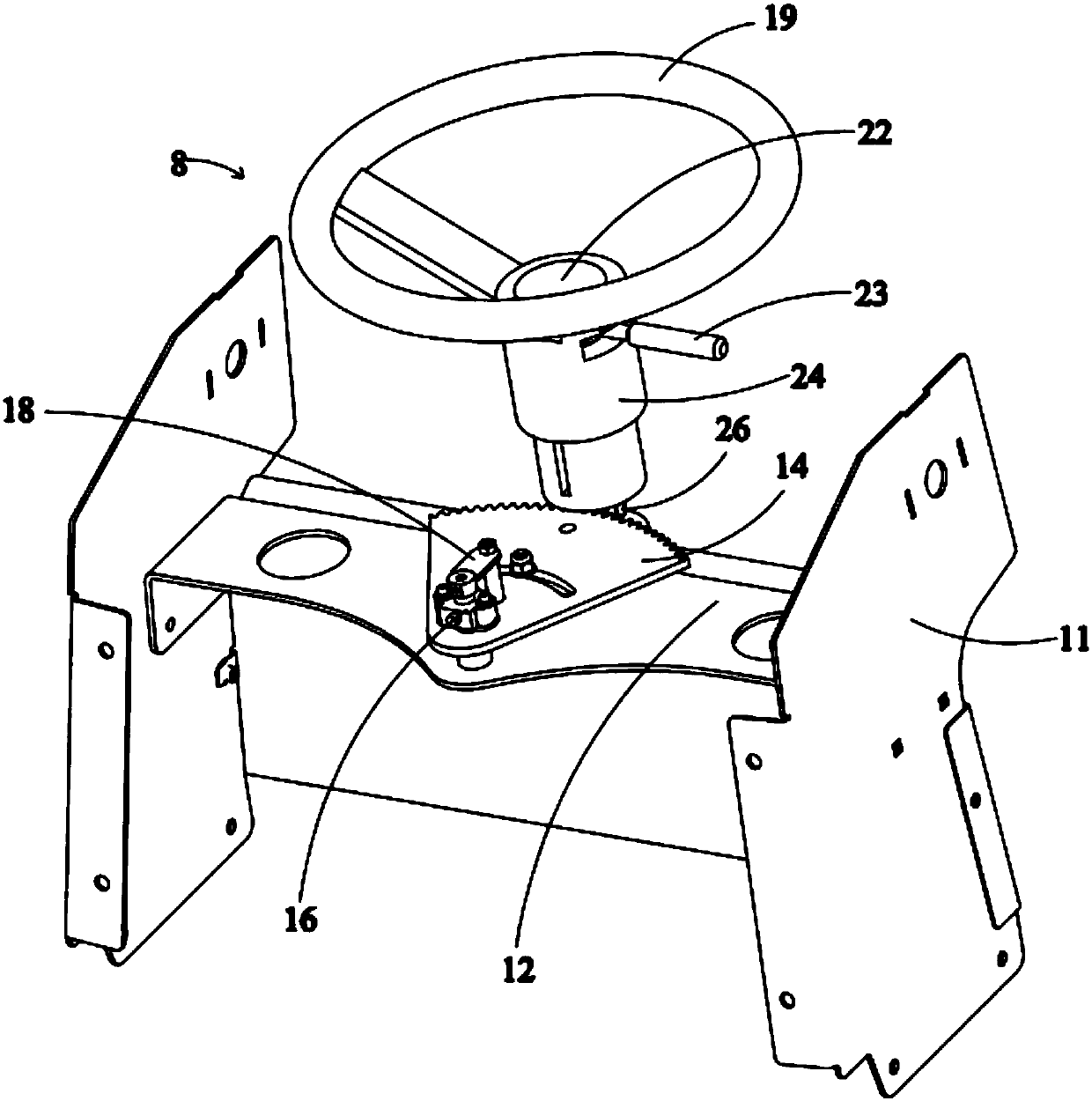

[0029] see figure 1 and figure 2 As shown, the present invention discloses a standing electric lawnmower 100, comprising: an electrical control assembly, a pair of rear wheels 1, two rear wheel drive axles 2, a mowing assembly 3, a frame 4, a pair of front Wheel 5, battery protection cover 6, battery pack 7, manipulation component 8 and height adjustment component 9, etc. The trailing wheel 1, the trailing wheel drive axle 2 and the front wheel 5 form a walking assembly. The electrical control component is used to control the operation of the walking component, the mowing component 3 , the battery pack 7 and the manipulation component 8 .

[0030] The rear wheel 1 is fixed on the output end flange of the rear wheel drive axle 2 by bolts.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com