Welding tool box

A technology for welding tools and boxes, which is applied in the field of welding tool boxes, can solve problems such as leakage, and achieve the effects of avoiding leakage, convenient transportation, storage and storage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

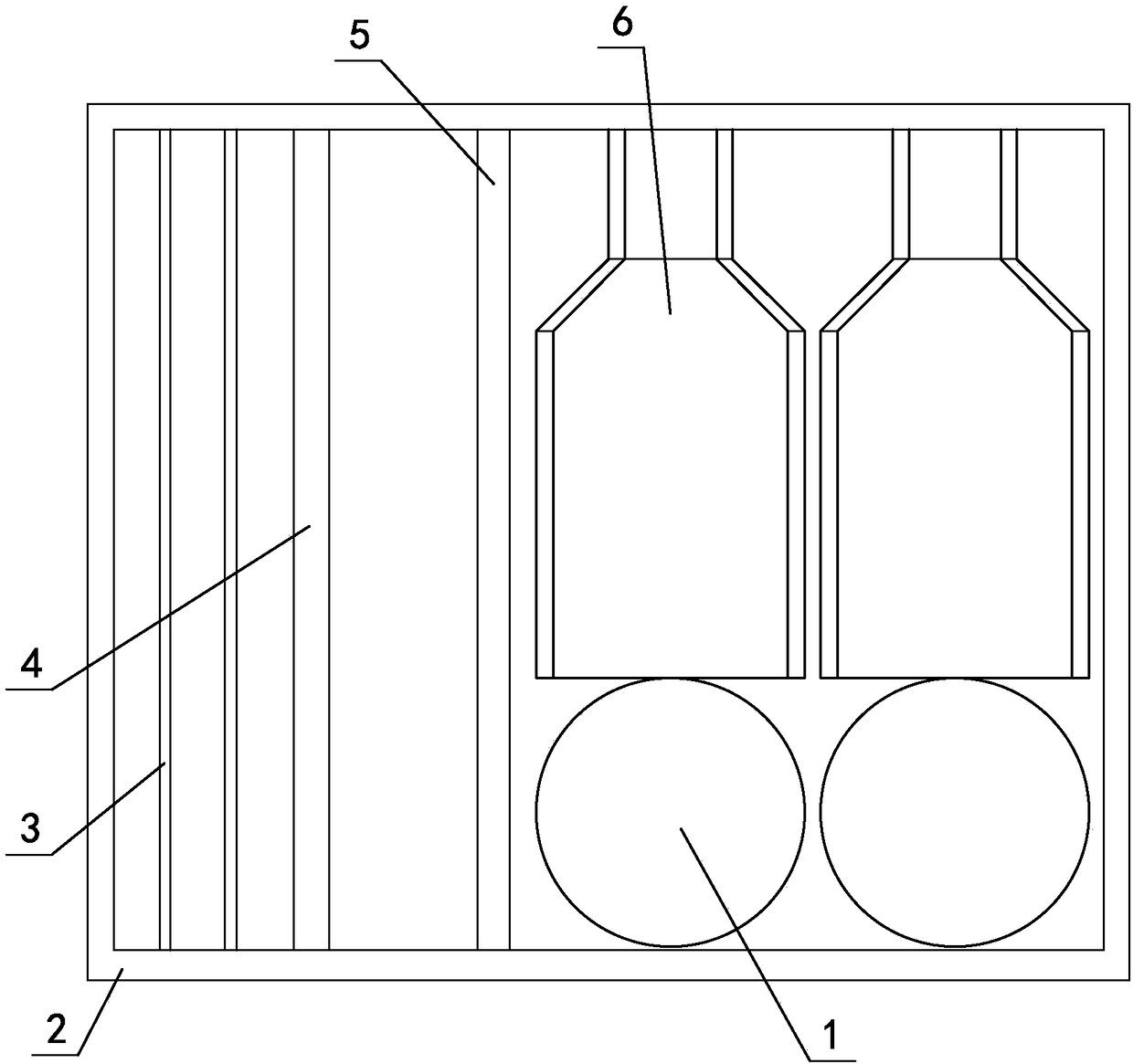

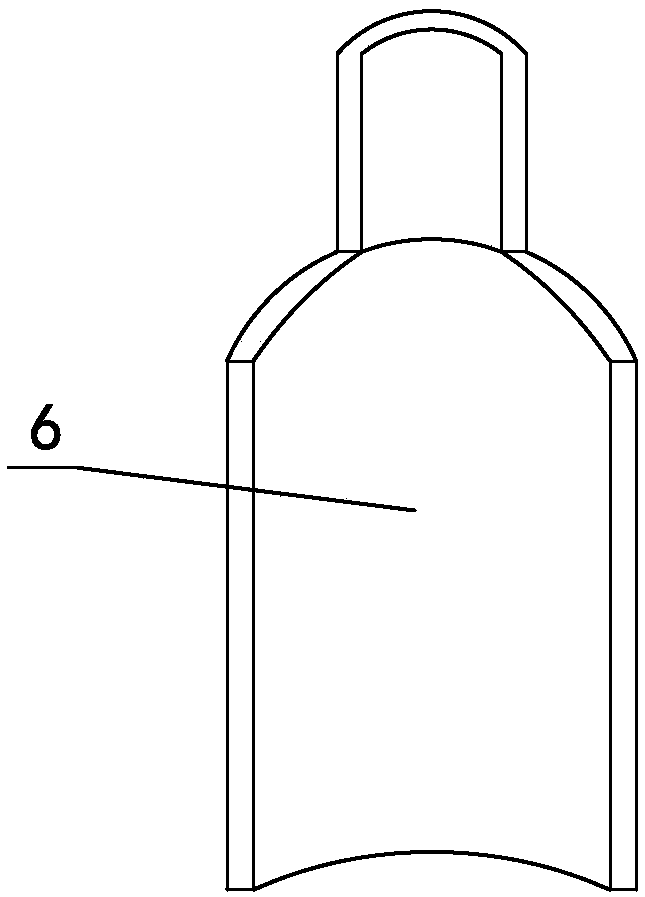

[0017] Such as figure 1 , figure 2 As shown, the welding tool box includes a box body 2, a box cover is provided on the box body 2, a second partition plate 4 and a third partition plate 5 are arranged in the box body 2, and the second partition plate 4 and the third dividing plate 5 divide the box body 2 into three placement areas, which are welding wire placement area, welding tool placement area and gas tank placement area from left to right, and there are two parallel arrangements in the gas tank placement area for Buckle the tank body placement groove 6 of the gas tank, the groove structure of the tank body placement groove 6 matches the gas cylinder, and two tank body placement grooves 6 are provided with placement holes 1 for vertically placing the gas tank.

[0018] In this embodiment, the welding wire placement area is provided with at least two first partition plates 3, thereby dividing the welding wire placement area into a plurality of welding wire placement spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com