Automatic disk stacking device for security line collection disk

A storage tray and stacking tray technology, applied in transportation and packaging, object stacking, conveyors, etc., can solve the problems of high labor cost, manual handling, and low work efficiency, and achieve low production cost, easy manufacturing and processing, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

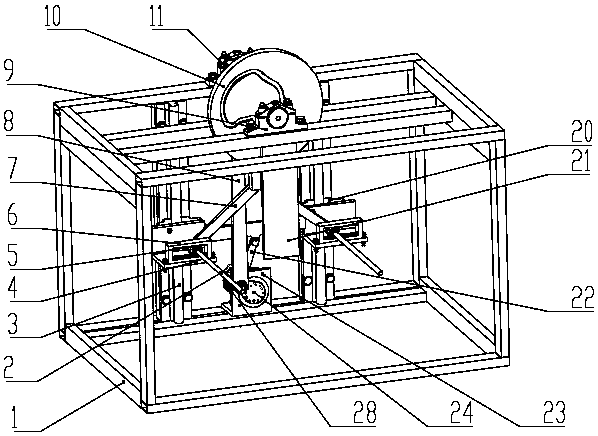

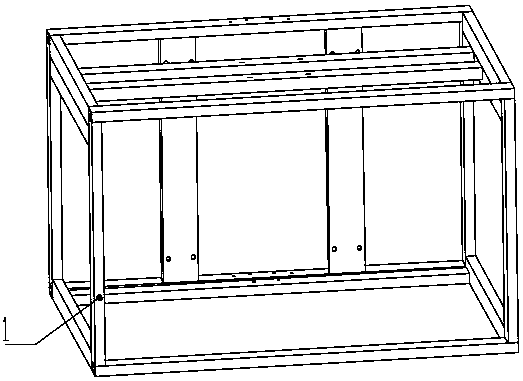

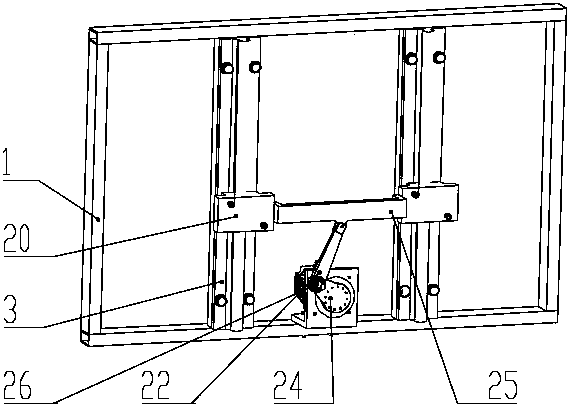

[0016] Such as Figure 1-7 As shown, the present invention comprises frame 1, motor base 23, speed reducer 28, servo motor 27, lifting plate mechanism and stacking plate mechanism; Described frame 1 adopts pipe profile weldment, and motor base 23 is fixed on machine On the frame 1, the reducer 28 is fixed on the motor base 23 by screws, and the servo motor 27 is fixed on the reducer 28 by screws; , bearing pin 26, connecting rod 22 and U-shaped bar 25; Described two linear guide rails 3 are fixed on the frame 1 with bolts respectively, and two slide tables 20 are respectively installed on the two linear guide rails 3 to form a moving pair, lifting crank 24 One end is fixedly connected with the output flange of the reducer 28, the other end of the lifting crank 24 is hinged with one end of the connecting rod 22 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com