Aluminum alloy plate with high natural aging stability and high baking hardening performance

An aluminum alloy sheet and natural aging technology, which is applied in the field of sheet and its manufacturing, can solve the problems of low cost, affecting appearance, undisclosed effect of natural aging stability of aluminum alloy for automobile body panels, etc., to improve strength and reduce free space Concentration, the effect of promoting the age hardening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

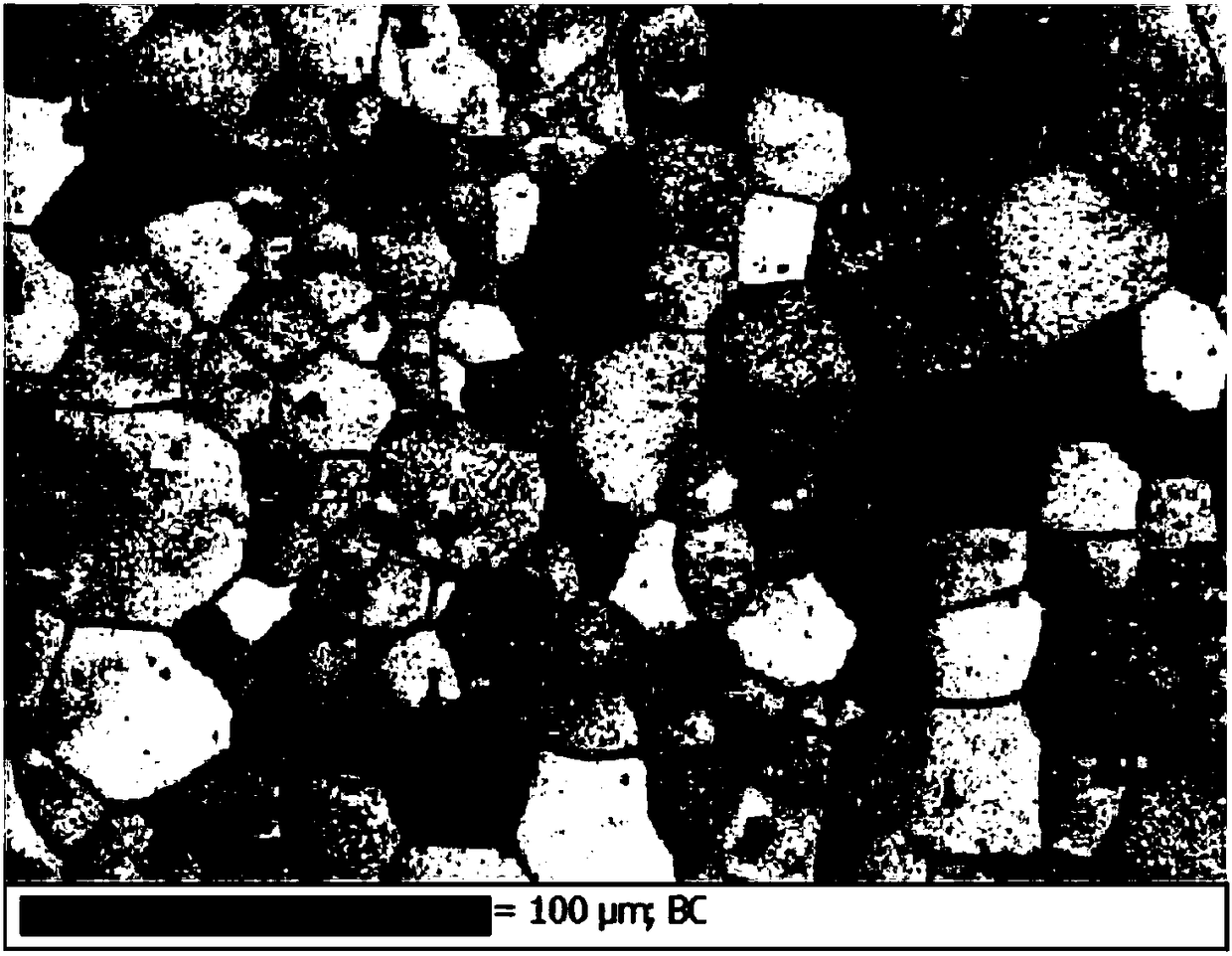

Image

Examples

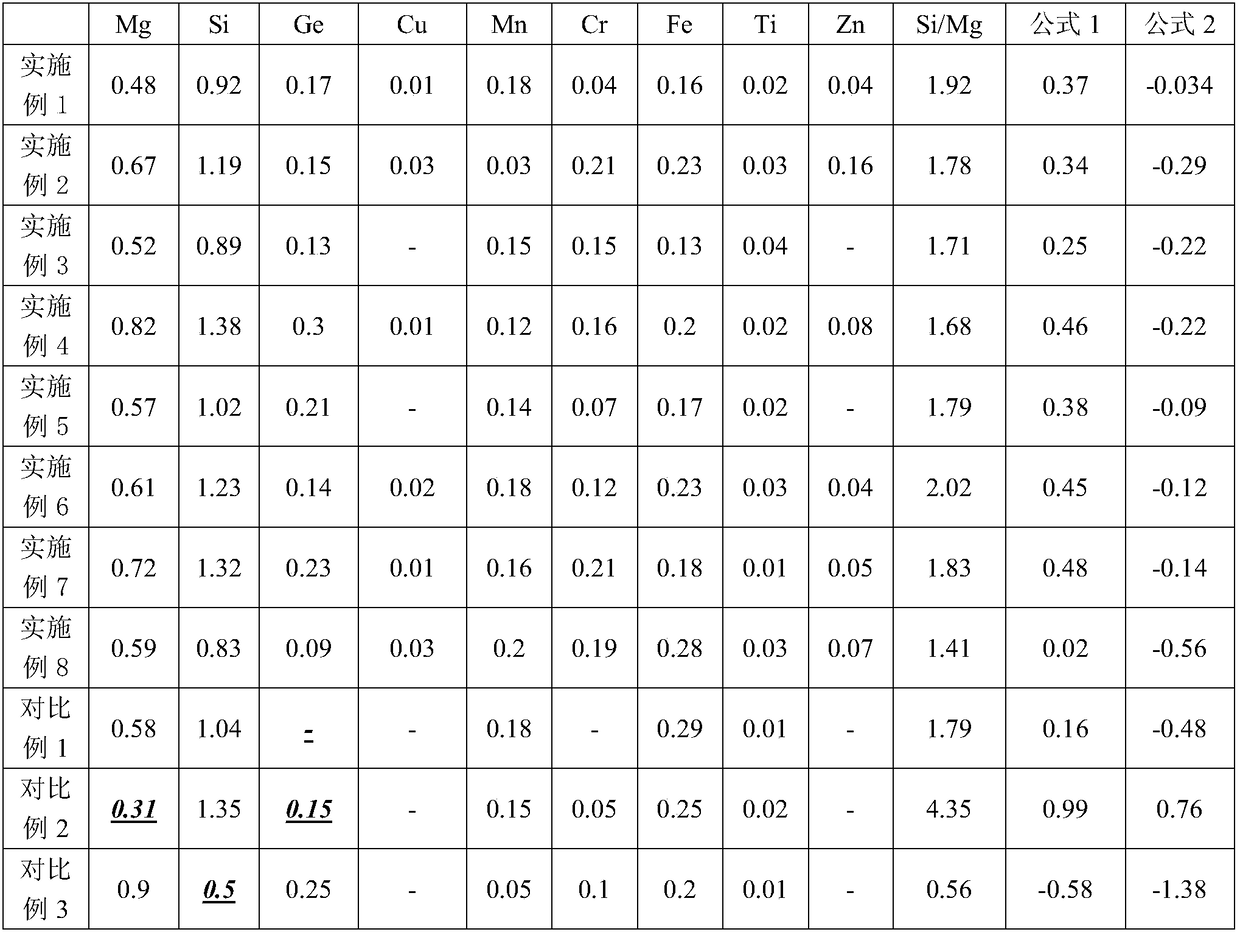

Embodiment 1-8 and comparative example 1-3

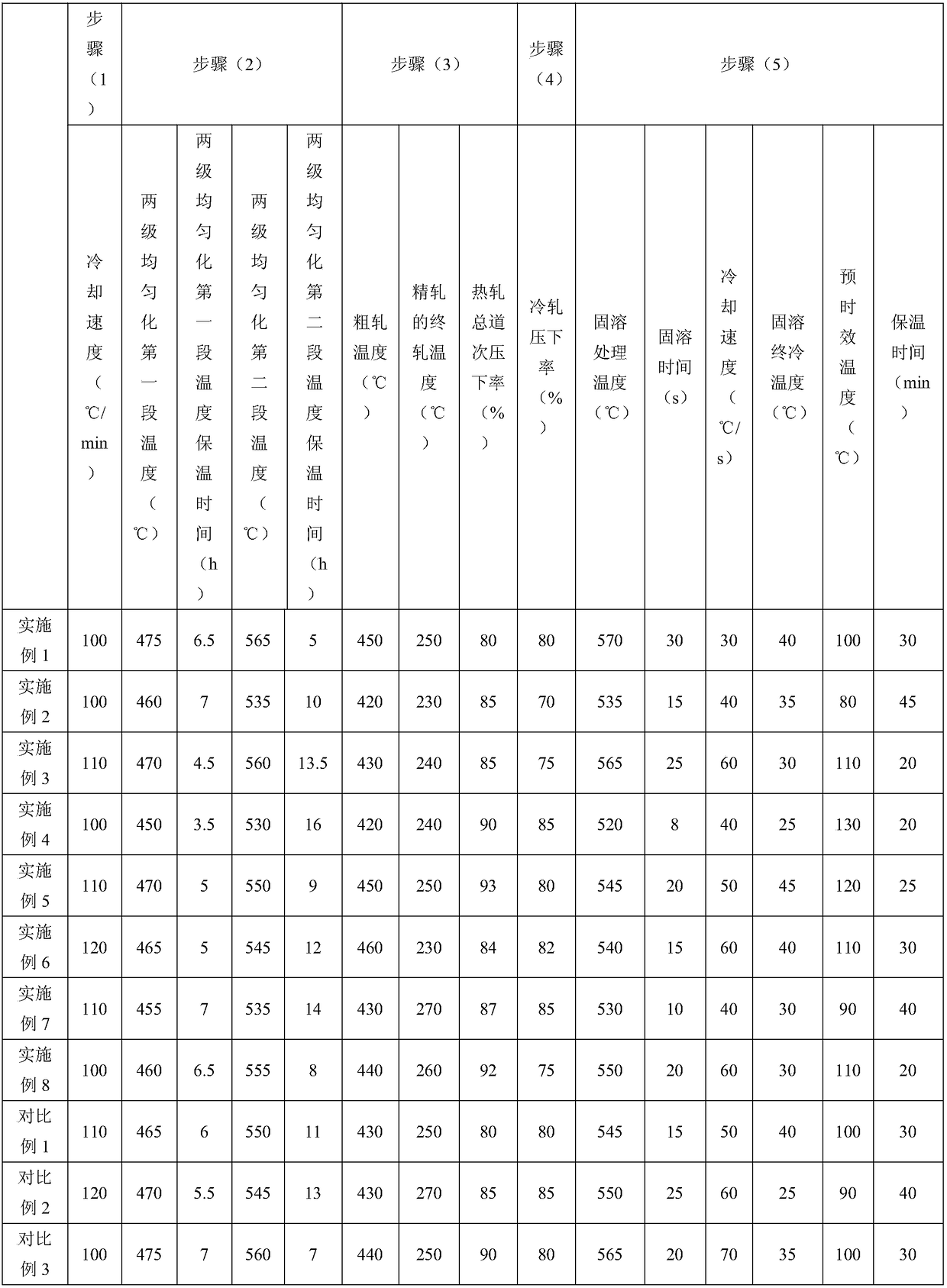

[0052] The aluminum alloy plates of Examples 1-8 and Comparative Examples 1-3 were prepared by the following steps:

[0053] (1) Cast ingots by semi-continuous casting method according to the percentage distribution of each chemical element in Table 1. During semi-continuous casting, rapidly cool from liquidus temperature to solidus temperature at a cooling rate of not less than 100°C / min ;

[0054] (2) Homogenization of the ingot: Carry out two-stage homogenization: the ingot is first kept at 450-480°C for 3-8h, and then at 520°C-570°C for 3-16h. ;

[0055] (3) Hot rolling: hot rolling includes rough rolling and finish rolling, wherein the rough rolling temperature is 400-500°C, the finish rolling temperature is 220-300°C, and the total pass reduction rate of hot rolling is greater than 75%;

[0056] (4) Cold rolling: cold rolling reduction rate is 60-90%;

[0057] (5) Solution treatment and pre-aging treatment are completed on the continuous heat treatment line: the solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com