Fabrics blended by bundle fiber flax and air-conditioning fiber and preparation process thereof

A technology of air-conditioning fiber and preparation process, which is applied in the direction of chemical production of bast fiber, textiles, papermaking, and yarn, etc., can solve the problems of limited temperature reduction of fabrics and inability to feel sufficient cooling by the human body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

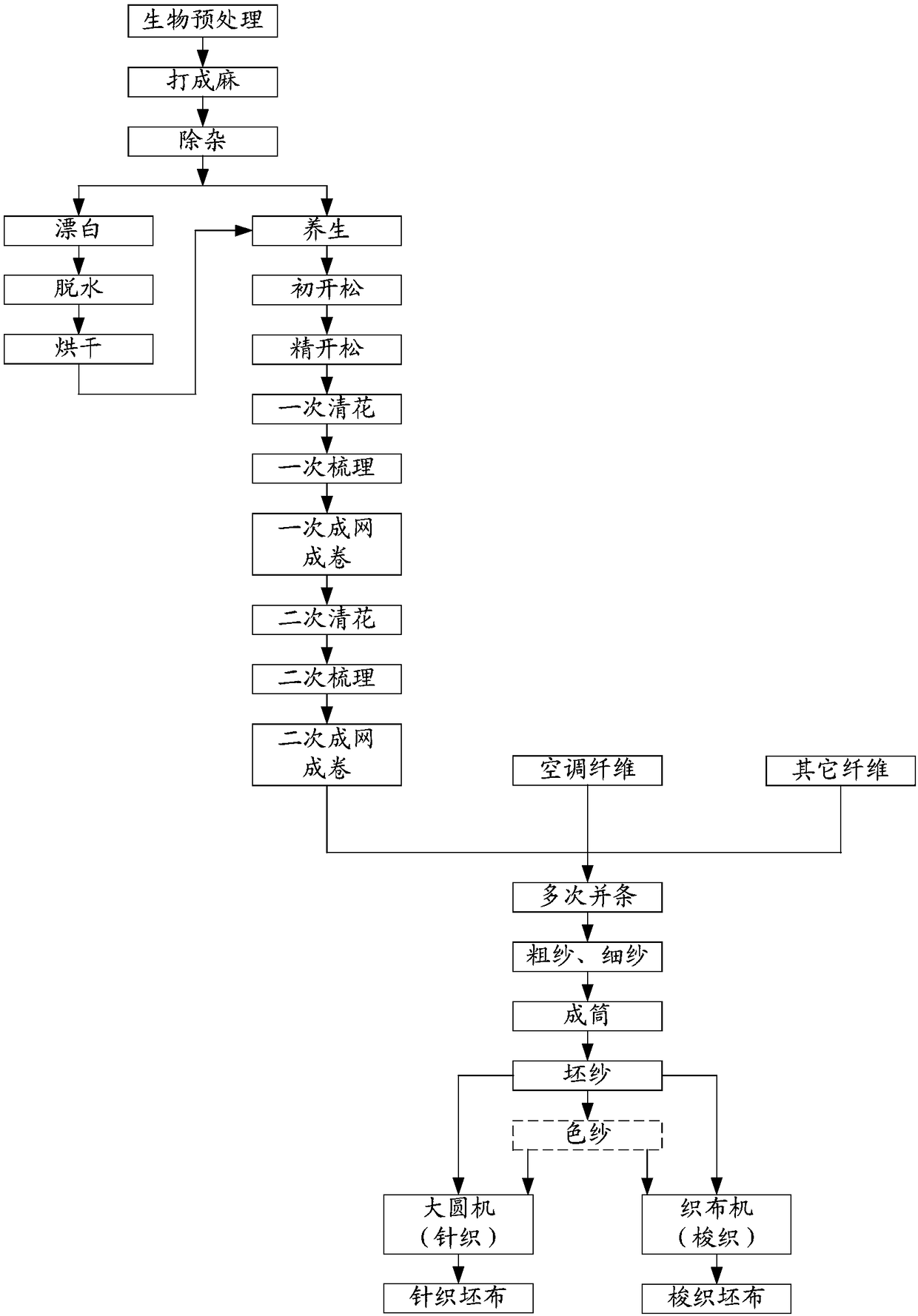

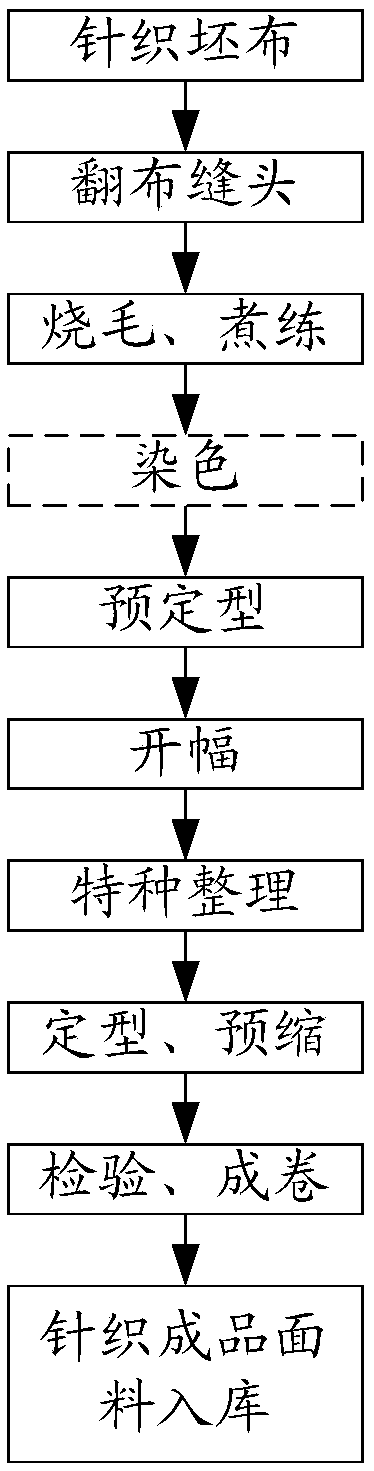

[0039] figure 2 It is a process flow diagram of the preparation process of finished knitted fabric according to the present invention, and the obtained knitted gray fabric is sequentially turned over and seamed, singed, scoured, dyed (the dyeing process is optional according to the actual situation), pre-set, and opened. Weaving, special finishing, shaping, pre-shrinking, inspection and rolling processes, so as to prepare knitted finished fabrics and put them into storage.

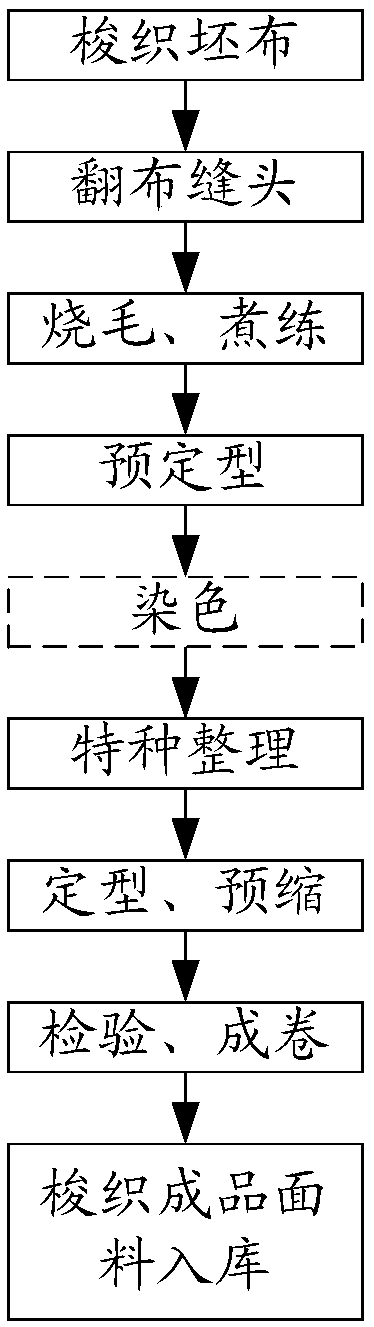

[0040] image 3 According to the process flow chart of the preparation process of the finished woven fabric of the present invention, the obtained woven gray fabric is sequentially turned over and seamed, singed, scoured, pre-shaped, and dyed (the dyeing process is optional according to the actual situation) , special finishing, shaping, pre-shrinking, inspection and rolling processes, so as to prepare woven finished fabrics and put them into storage.

[0041] in, figure 1 Dyed yarn treatment in Figu...

Embodiment 1

[0045] Prepare respectively 5 kilograms of hemp, 15 kilograms of flax and 5 kilograms of fiber hemp of Apocynum apocynum for subsequent use as raw materials; The mannanase of 8wt%, the neutral cellulase of 15wt% and the esterase of 5wt% are mixed together to form enzyme mixture, and described enzyme mixture is pH 8-9, temperature is 30 ℃ and humidity is 95% - 100% applied to the bundle fiber hemp for 7 days, and then based on the weight of the bundle fiber hemp, spray 1wt% emulsified oil after standing for 24 hours, thereby making the bundle fiber hemp Separate and detach from the hemp stem of the bundle of fiber hemp to obtain hemp; remove impurities from the hemp; perform health maintenance on the hemp after removal, specifically, based on the hemp after removal Describe the weight of making hemp, the pectinase of 40wt%, the xylanase of 30wt%, the mannanase of 10wt%, the neutral cellulase of 3wt% and 5wt% esterase are mixed together to form enzyme mixture After diluting 100...

Embodiment 2

[0048] Prepare 25 kilograms of flax as a raw material for subsequent use; Spray the flax for 8 days under the conditions of 7.5-8.5, temperature 35°C and humidity of 95%-100% with the Erwinia bacillus of directional culture, and then based on the described The weight of flax, after spraying the emulsified oil of 1.5wt% and standing for 24 hours, so that the hemp bark of the flax is separated from the hemp stalk of the flax and separated to obtain beating hemp; the beating hemp is removed Carry out health preservation to the described hemp after impurity removal, specifically, based on the weight of the hemp after impurity removal, 30wt% pectinase, 25wt% xylanase, 6wt% manna Glycanase, 5wt% neutral cellulase and 4wt% esterase are mixed together to form an enzyme mixture and then diluted 100 times with water, then the diluted enzyme mixture and linseed oil are mixed in a weight ratio of 1:0.5 After mixing, spray the crushed hemp at a temperature of 40°C for 7 days; put the crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com