Piezoelectric high-speed high-flow two-position three-way valve

A 2/3-way valve, high flow technology, applied in the charging system, fuel injection device, machine/engine, etc., can solve the problem that it is difficult for the spring to ensure the same precise elastic force, the control accuracy of the solenoid valve is not high, and it is difficult to electromagnetically Valve response speed and other issues, to achieve the effect of solving long-term work fever, improving service life and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with specific examples.

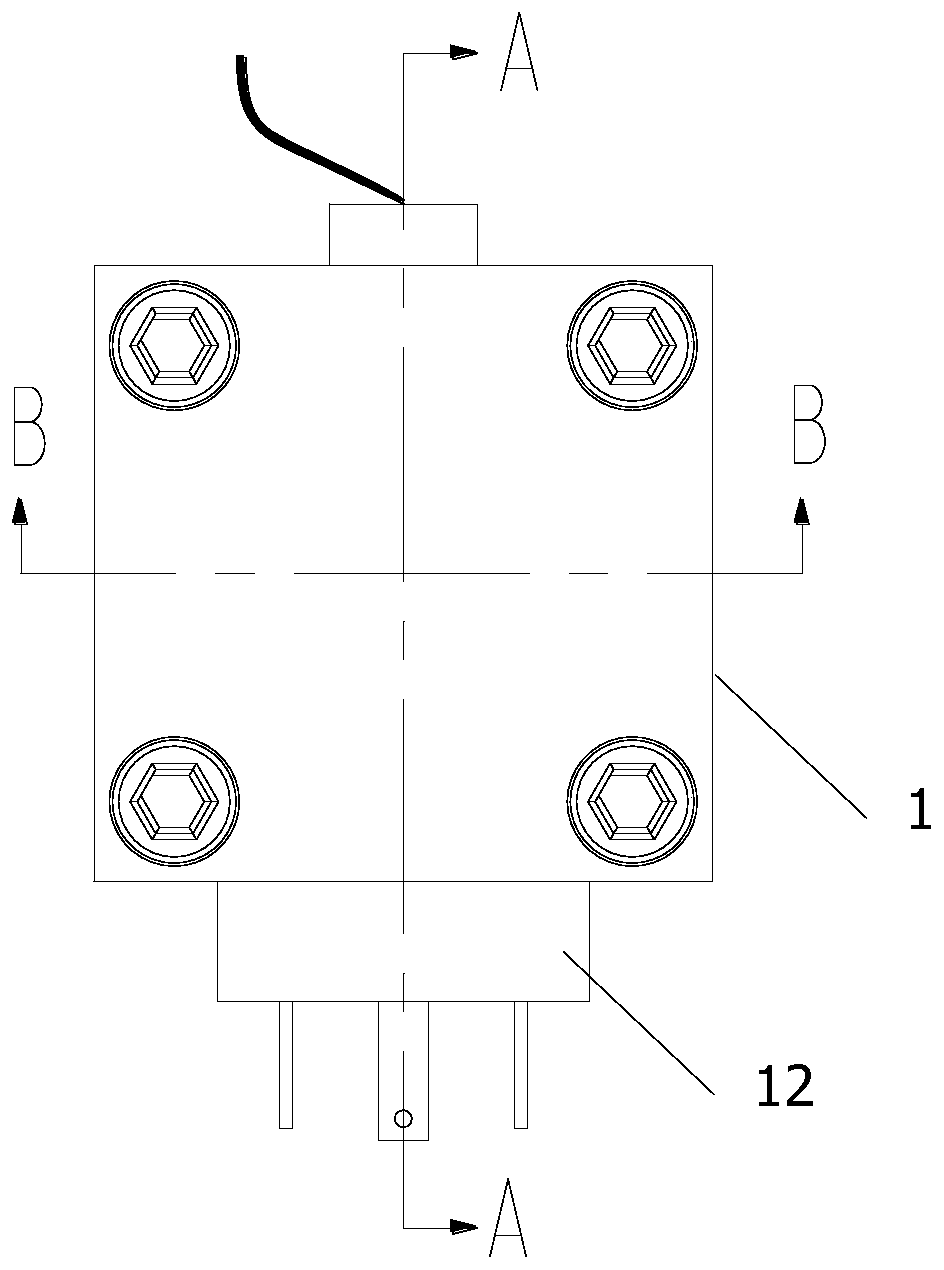

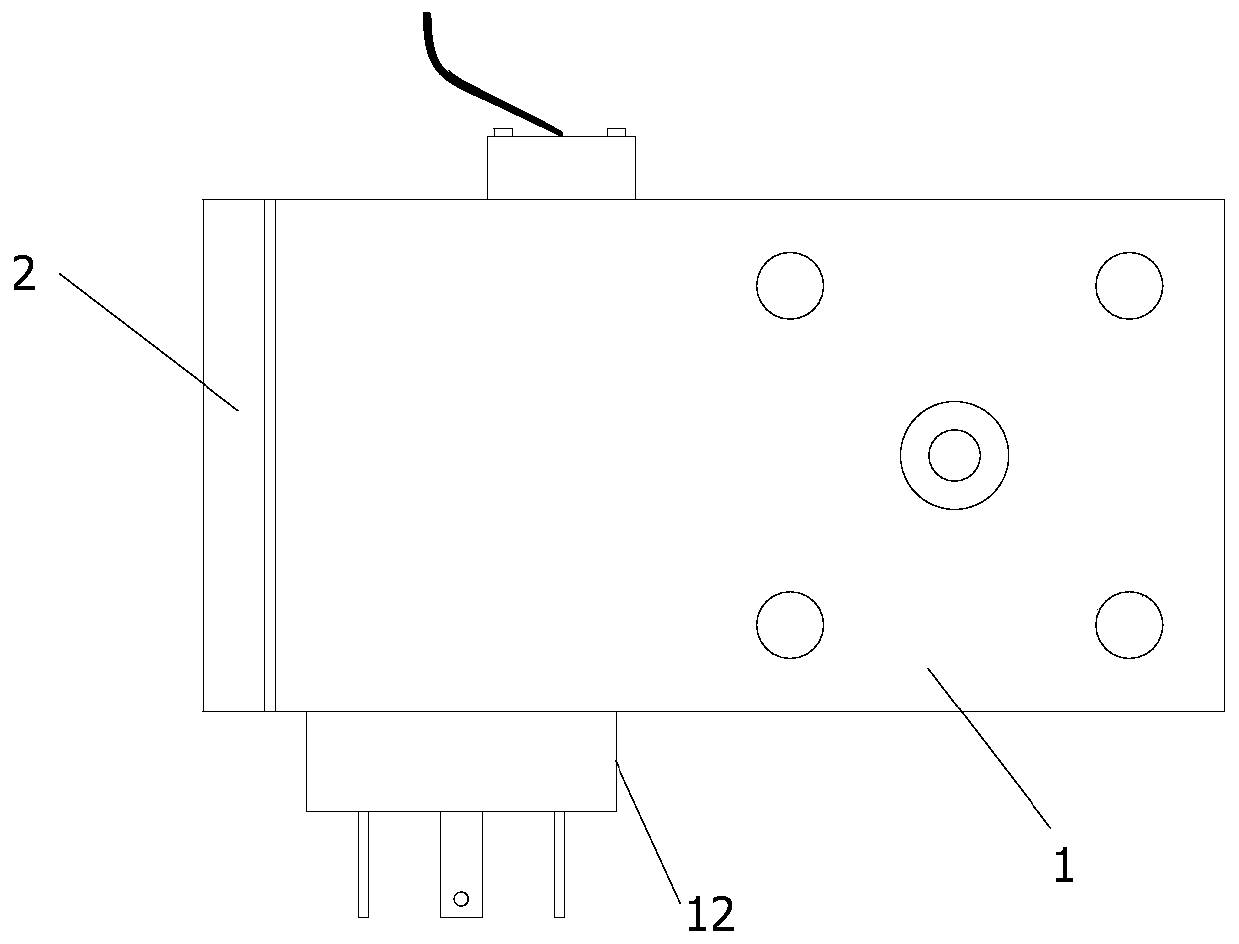

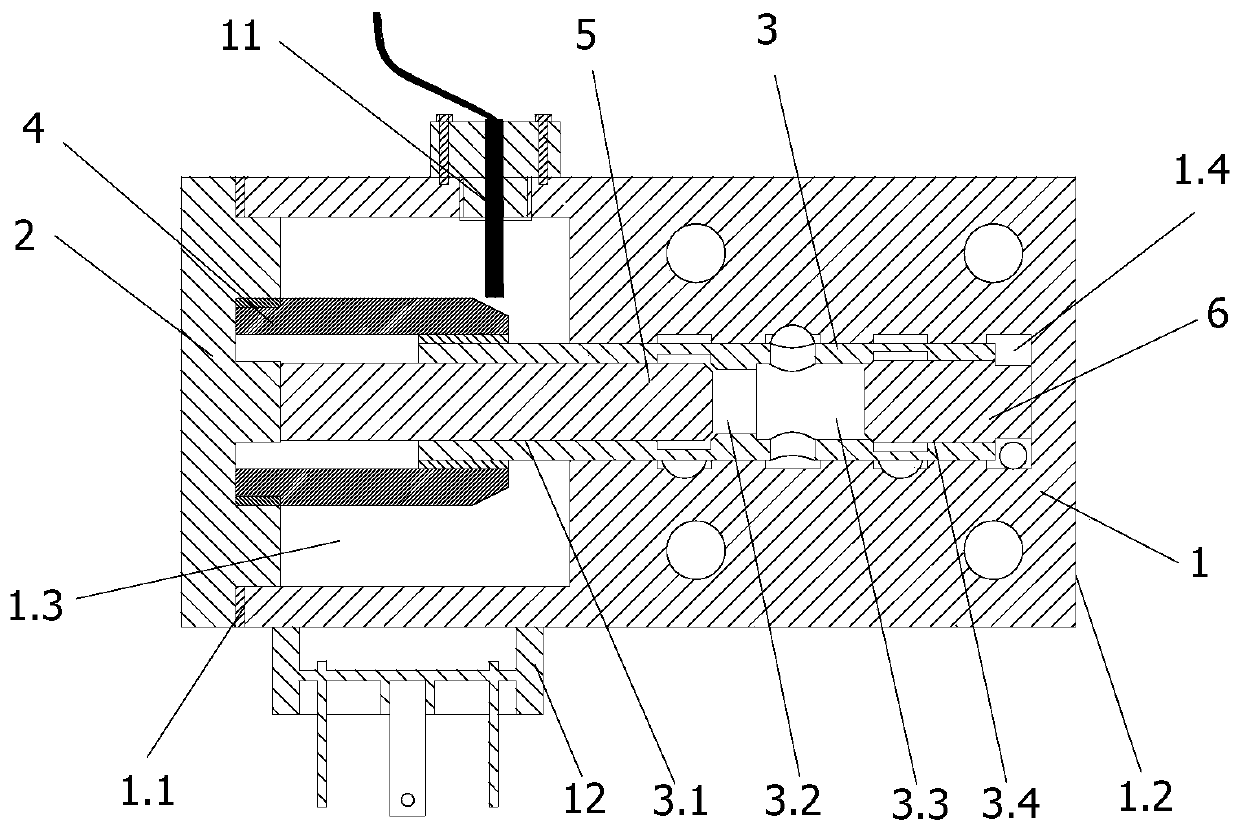

[0033]As shown in the figure, a piezoelectric high-speed and large-flow two-position three-way valve includes a valve body 1 with an open end 1.1 and a closed end 1.2. The open end 1.1 of the valve body 1 is provided with a valve cover 2, and the valve body 1 The inner cavity is a stepped cavity formed by the first cavity 1.3 and the second cavity 1.4; the first cavity 1.3 is pierced with an outer spool 3, and one end of the outer spool 3 extends to the closed end 1.2 of the valve body 1, and the outer spool 3 The other end of the spool 3 extends toward the open end 1.1 of the valve body 1 and penetrates into the second cavity 1.4; the second cavity 1.4 is provided with a ring-shaped and can be positioned between the outer spool 3 and the valve cover 2. The piezoelectric ring 4 deformed by electrification, the piezoelectric ring 4 can be made of piezoelectric ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com