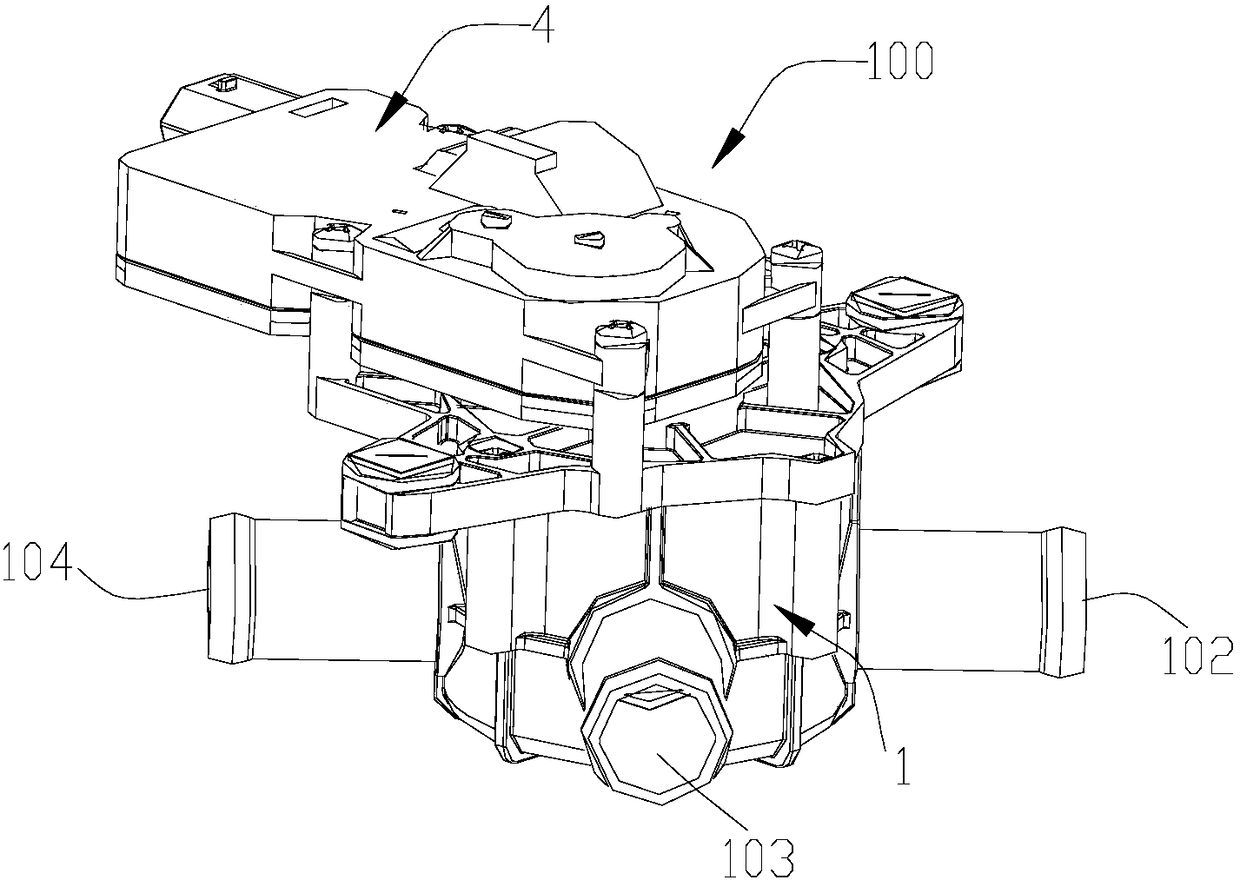

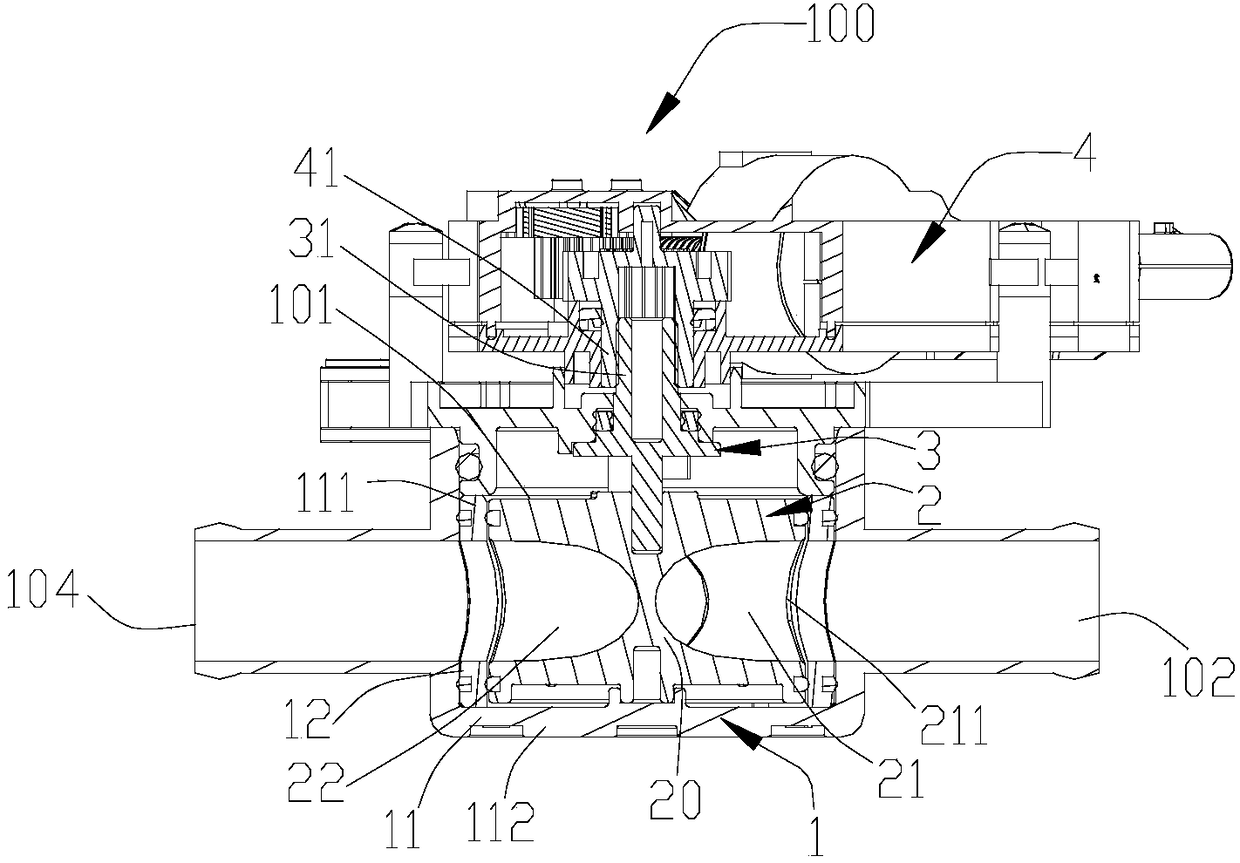

Flow control device

A technology of flow control device and flow channel, which is applied to valve devices, cocks including cut-off devices, multi-way valves, etc., which can solve the problems of reduced sealing performance and achieve the effect of improving internal sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

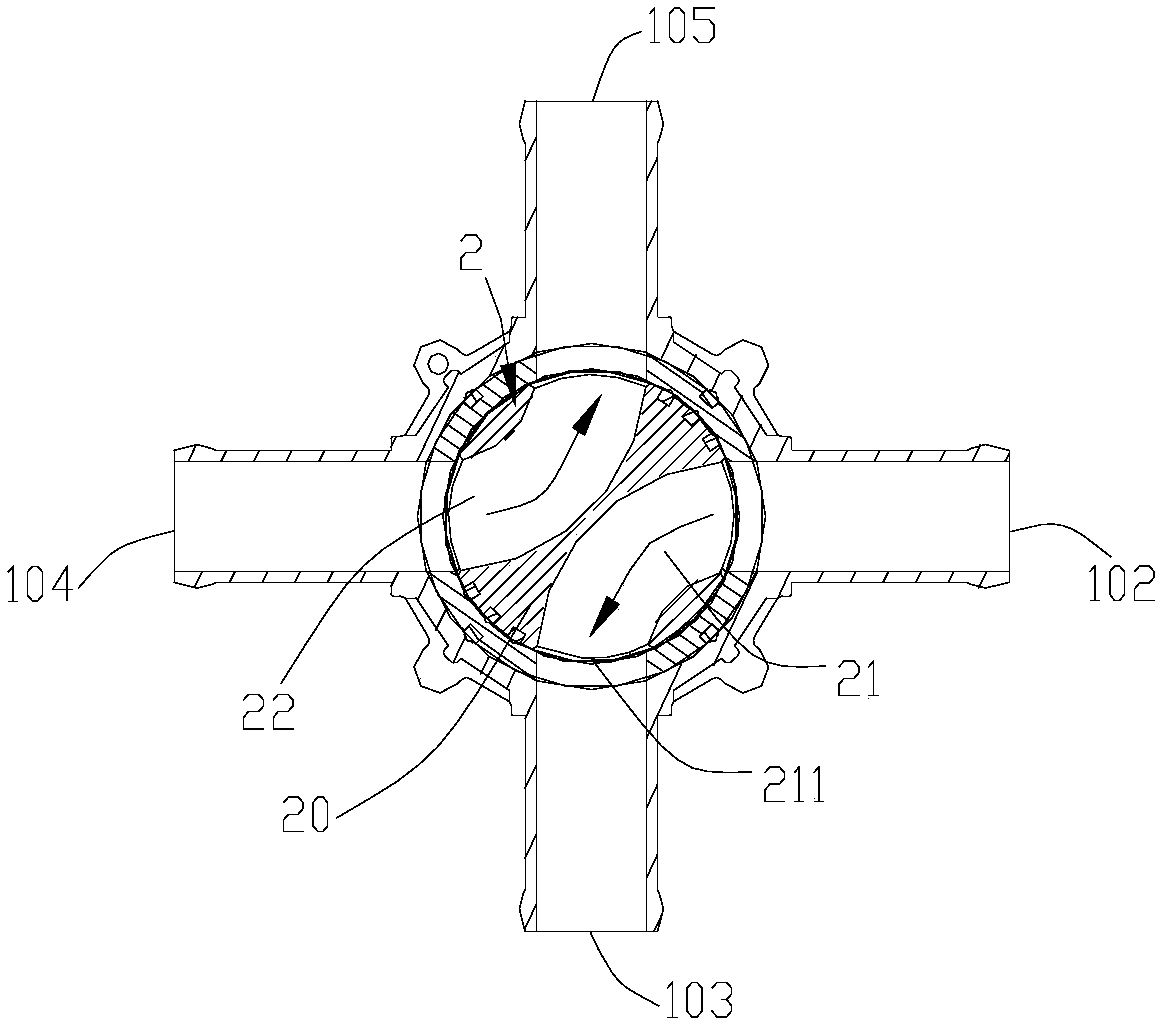

[0024] In other embodiments, the spool can be integrally formed with other materials such as ceramics, plexiglass, or metal, or a sealing contact structure of other materials such as ceramics, plexiglass, or metal is embedded on the outside of the spool 2, specifically the sealing contact portion of the spool 2 The main body part 20 protrudes outwards along the radial direction of the valve core, that is, the sealing contact part of the valve core 2 is fitted and assembled with the main body part 20 or the sealing contact part and the main body part 20 are integrally structured. The sealing contact part of 2 is a ceramic arc-shaped contact surface or a metal arc-shaped contact surface or a plexiglass arc-shaped contact surface. The surface roughness of the arc-shaped contact surface is greater than 0.03 μm and less than 0.48 μm, and the surface is relatively smooth to meet the sealing contact performance .

[0025] Driven by the transmission element, the spool 2 reciprocates a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com