Dynamic deflection instrument calibration method

A calibration method and the technology of the deflection meter, which are applied in the direction of instruments, measuring devices, and electrical devices, etc., can solve the problems of traceability and inability to give the indication value of the dynamic deflection meter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

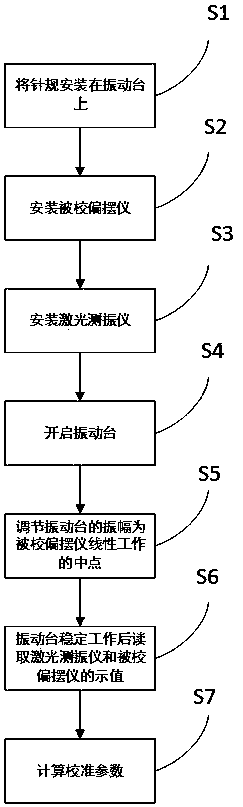

[0038] Such as figure 1 As shown, a dynamic deflection meter calibration method includes the following steps:

[0039] S1: Install the gauge on the vibration table;

[0040] S2: Install the pendulum to be calibrated;

[0041] S3: install the laser vibrometer;

[0042] S4: Turn on the vibration table;

[0043] S5: Adjust the amplitude of the vibrating table to the midpoint of the linear work of the pendulum to be corrected;

[0044] S6: Read the indications of the laser vibrometer and the calibrated pendulum after the vibration table works stably;

[0045] S7: Calculating calibration parameters.

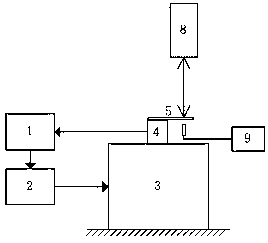

[0046] In this embodiment, install through steps S1-S3:

[0047] Wherein, in step S1, the standard needle gauge is installed on the installation platform that is located on the standard vibration table, and the standard needle gauge is installed to the appropriate position of the deflection meter measurement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com