Image sensor

An image sensor and photosensitive chip technology, applied in the field of sensors, can solve problems such as signal attenuation and distortion, and achieve the effect of preventing signal distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

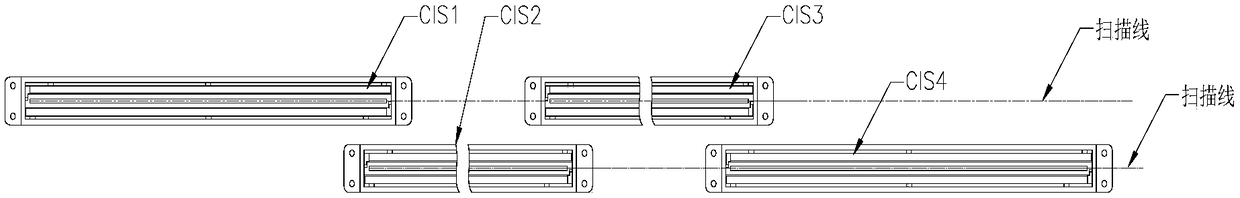

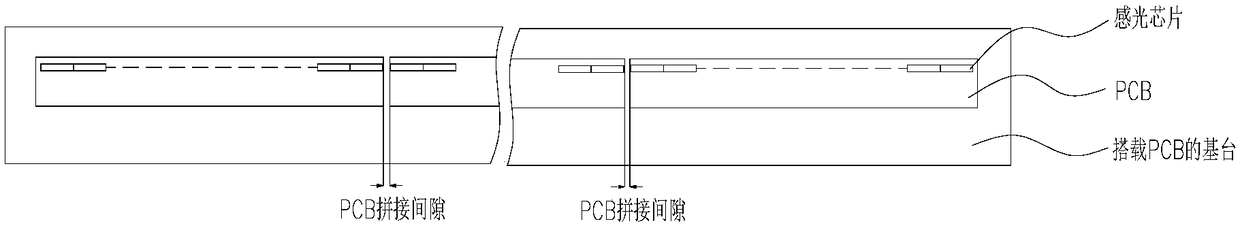

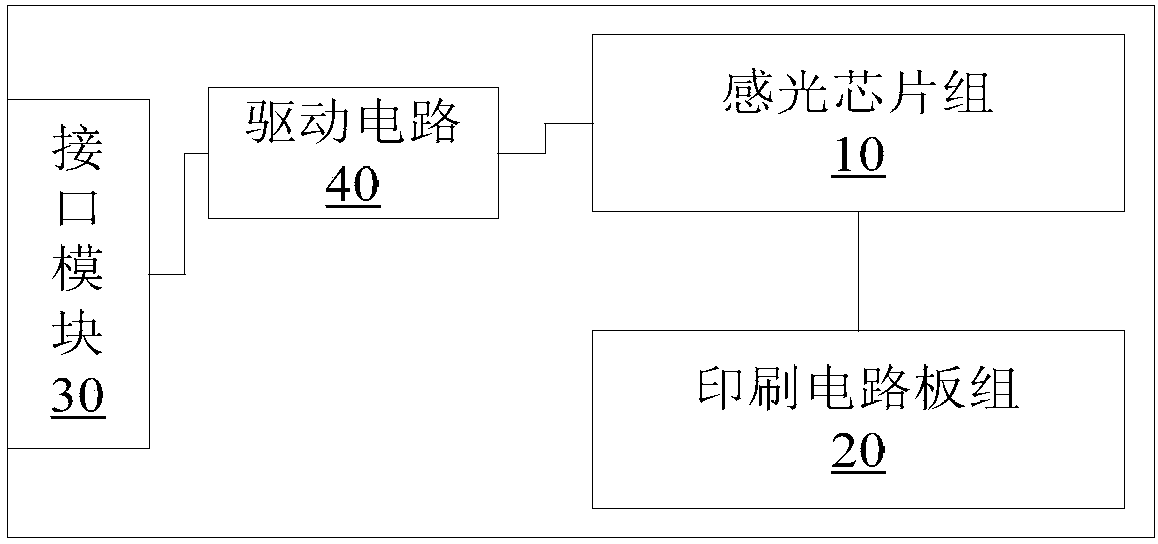

[0042] image 3 is a schematic diagram of an optional image sensor according to an embodiment of the present invention, such as image 3 As shown, the image sensor includes a photosensitive chip set 10, a printed circuit board set 20, an interface module 30 and a drive circuit 40, wherein the photosensitive chip set 10 includes a plurality of photosensitive chips connected in sequence along a preset direction, and each photosensitive chip is used for Convert the light sensed by itself into an electrical signal. In the case of a contact image sensor CIS, each photosensitive chip is used to sense the light reflected by the original, and convert the light reflected by the original sensed by itself into electric signal. The printed circuit board group 20 includes a plurality of printed circuit boards sequentially connected along a predetermined direction, each printed circuit board is connected to at least one photosensitive chip, and each printed circuit board is used to receive...

Embodiment 2

[0051] An image sensor such as Figure 8 As shown, the image sensor includes a light source 1 , a lens 2 , a photosensitive chip 3 , a printed circuit board 4 b , a frame 5 , a base 6 , metal wires 7 and an interface module 9 . The light emitted by the light source 1 is reflected by the original, and is collected by the lens 2 on the photosensitive chip 3 for photoelectric conversion. The electrical signal converted by the photosensitive chip 3 passes through the metal wire 7 and is transmitted to the outside through the interface 9 on the printed circuit board 4b. The base 6 is used to mount the printed circuit board 4 b, and the frame 5 is used to mount the light source 1 and the lens 2 .

[0052] The top view of the abutment 6 is as follows Figure 4 As shown, the right view is as Figure 5 As shown, the bottom view is as Image 6 As shown, a plurality of spliced printed circuit boards 4b and a non-wiring circuit board 4a are mounted on the base 6, and a plurality of p...

Embodiment 3

[0060] An image sensor such as Figure 12 As shown, the image sensor includes a light source 1 , a lens 2 , a photosensitive chip 3 , a printed circuit board 4 b , a frame 5 , a base 6 , metal wires 7 and an interface module 9 . The light emitted by the light source 1 is reflected by the original, and is collected by the lens 2 on the photosensitive chip 3 for photoelectric conversion. The electrical signal converted by the photosensitive chip 3 passes through the metal wire 7 and is transmitted to the outside through the interface 9 on the printed circuit board 4b. The base 6 is used to mount the printed circuit board 4 b, and the frame 5 is used to mount the light source 1 and the lens 2 .

[0061] The top view of the abutment 6 is as follows Figure 13 As shown, the right view is as Figure 14 As shown, the bottom view is as Image 6As shown, a plurality of spliced printed circuit boards 4 b are mounted on the base 6 , and a plurality of photosensitive chips 3 are spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com