Device and method for removing elemental mercury in active coke

A technology of active coke and elemental mercury, which is applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of difficult recycling, secondary pollution, etc., and achieve the effects of low cost, efficient removal, and simple device operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

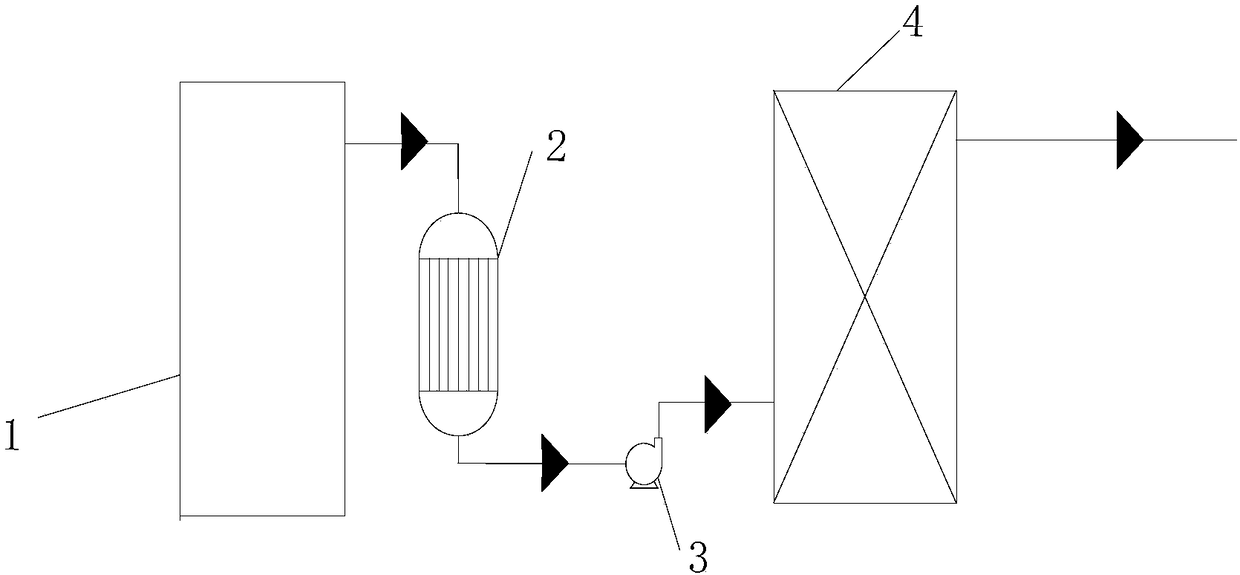

[0024] A method for removing mercury from mercury-containing active coke, specifically comprising the following steps:

[0025] Fill the mercury-containing active coke into the active coke filler, adjust the gas output of the ozone generator to 1g / h, the generated gas enters the heat exchanger through the pipeline, heats the ozone gas to 100°C, blows it through the blower, and then enters it from the pipeline In the active coke filler, there is 1m in the active coke filler 3 The mercury content is 10μg / m 3 After 30 minutes, the active coke was taken out and washed with water, and the mercury removal rate of the active coke reached 99.3%.

Embodiment 2

[0027] A method for removing mercury from mercury-containing active coke, specifically comprising the following steps:

[0028] Fill the mercury-containing active coke into the active coke filler, adjust the gas output of the ozone generator to 2g / h, the generated gas enters the heat exchanger through the pipeline, heats the ozone gas to 100°C, blows it through the blower, and then enters it from the pipeline In the active coke filler, there is 1m in the active coke filler 3 The mercury content is 10μg / m 3 After 30 minutes, the active coke was taken out and washed with water, and the mercury removal rate of the active coke reached 99.7%.

Embodiment 3

[0030] A method for removing mercury from mercury-containing active coke, specifically comprising the following steps:

[0031] Fill the mercury-containing active coke into the active coke filler, adjust the gas output of the ozone generator to 3g / h, the generated gas enters the heat exchanger through the pipeline, heats the ozone gas to 100°C, blows it through the blower, and then enters it from the pipeline In the active coke filler, there is 1m in the active coke filler 3 The mercury content is 10μg / m 3 After 30 minutes, the active coke was taken out and washed with water, and the mercury removal rate of the active coke reached 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com