V-shaped jaw crusher

A jaw crusher and cavity technology, applied in grain processing and other directions, can solve the problems of increased height stroke, reduced output, power loss, etc., and achieve the effects of large stroke speed, low wear rate, and large feed particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

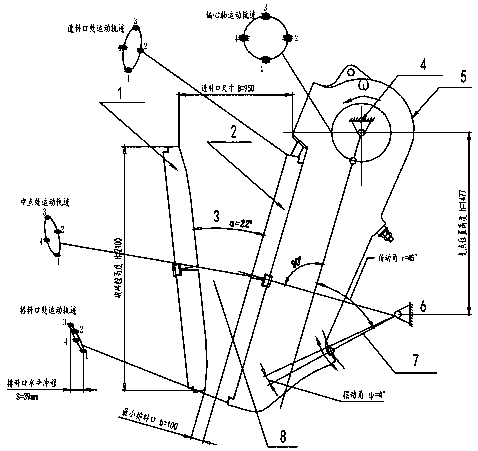

[0008] Embodiment 1: with reference to attached figure 1 . A V-cavity jaw crusher, including the jaw crusher. The structure of the jaw crusher itself belongs to the prior art. This application is based on the existing jaw crusher through the assembly structure of the jaw crusher The further improvement of the machine has brought unexpected technical effects----the discharge port has been increased from 150 tons to 310 tons per hour to 290 tons to 800 tons. In the jaw crusher, the distance between the fulcrum position 6 of the toggle plate 7 and the suspension point position 4 of the movable jaw 5 is 1477 ± 0.5 mm, and the meshing angle 3 between the fixed plate 1 and the movable plate 2 is α22 ± 0.5 degrees. Cavity 8 is a V-shaped cavity with a lower opening, with a height of 2100±0.5 mm, a material inlet of 950±0.5 mm, a minimum discharge port of 100±0.5 mm, a horizontal stroke of 39±0.5 mm, and discharge port per hour 290 tons to 800 tons. The transmission angle between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com