Adjustable pulse vortex generator

A generating device and pulse airflow technology, which is applied in transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of complex control system and control components, pulse swirl can not be adjusted, swirl effect can not be guaranteed, etc., to achieve adjustment The method is simple and convenient, the structure is simple and reliable, and the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

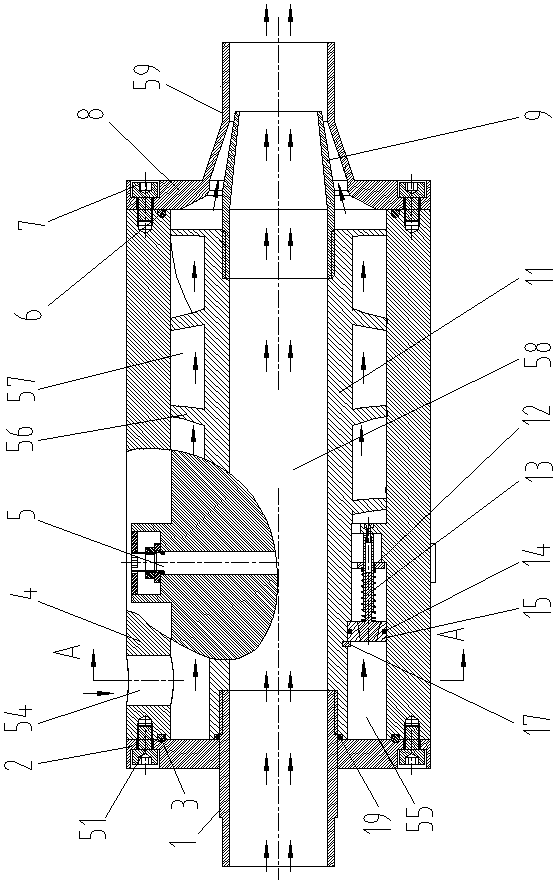

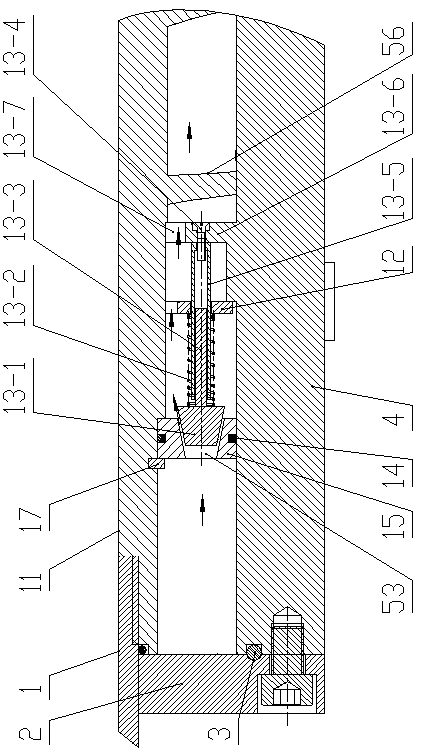

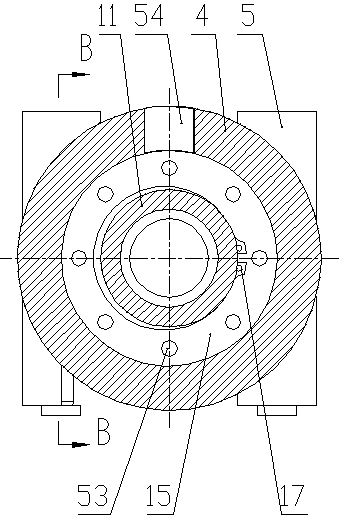

[0024] like Figure 1-Figure 6 As shown, an adjustable pulse swirl generating device of the present invention includes a split casing, an inlet pipe 1, a pulse air inlet orifice plate 15, a guide rod type one-way inlet valve 13, and a pulse air flow intensity adjustment plate 12 , Ratchet-type self-locking adjusting rod assembly 5, axially rotating vane tube 11 and outlet adjusting tube 9;

[0025]The split casing includes a left casing 2, a middle casing 4 and a right casing 8 coaxially arranged along the left and right directions, the middle casing 4 is a cylindrical structure, and the left end surface of the left casing 2 and the middle casing 4 The first O-ring 3 is arranged between them and is fastened and connected by the left screw 51, and the second O-ring 6 is arranged between the right housing 8 and the right end surface of the middle housing 4 and is fastened by the right screw 7. Connection, the axially rotating vane pipe 11 is coaxially arranged in the middle cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com