Alfalfa seed coating agent suitable for saline and alkaline land as well as preparation method thereof

A technology of coating agent and saline-alkali land, applied in the field of alfalfa seed coating agent and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

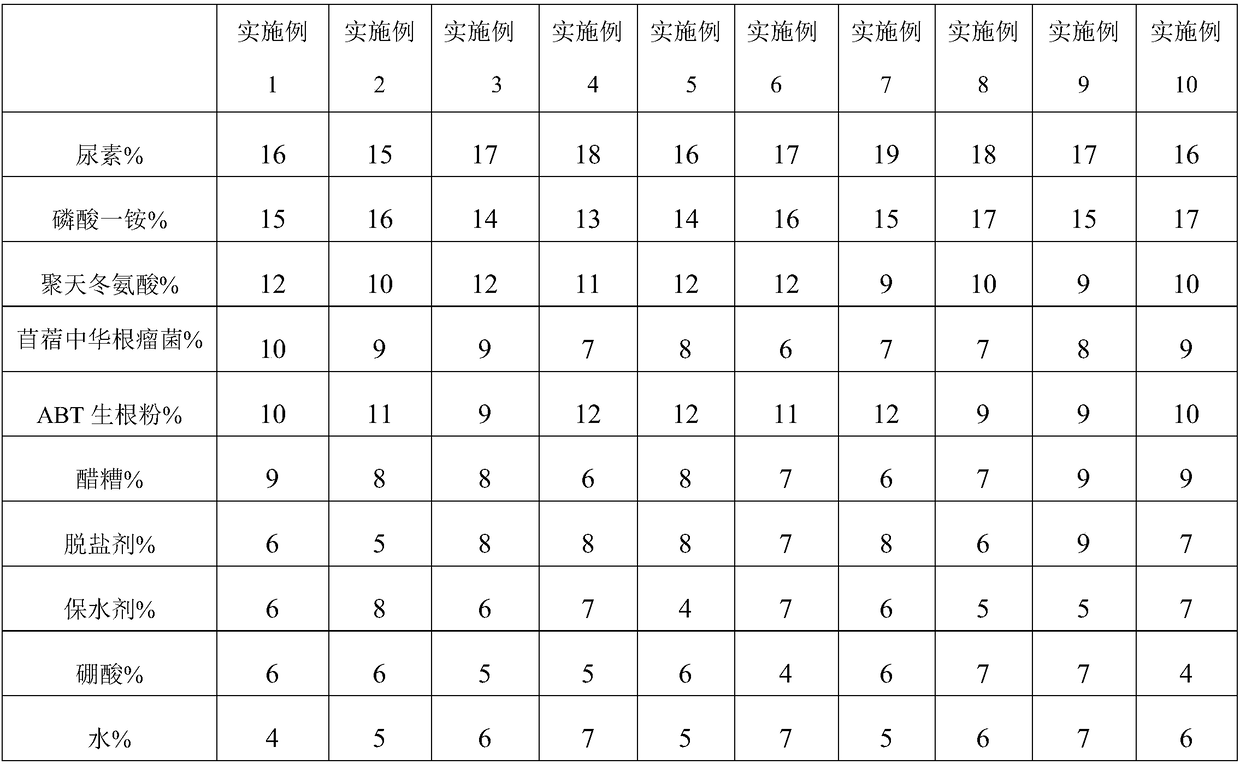

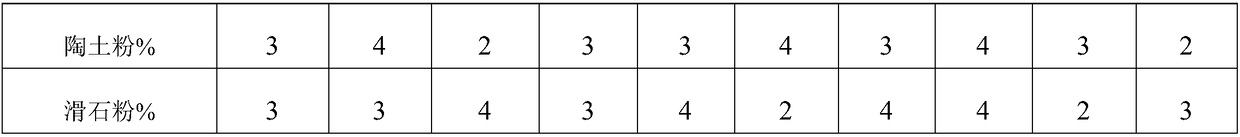

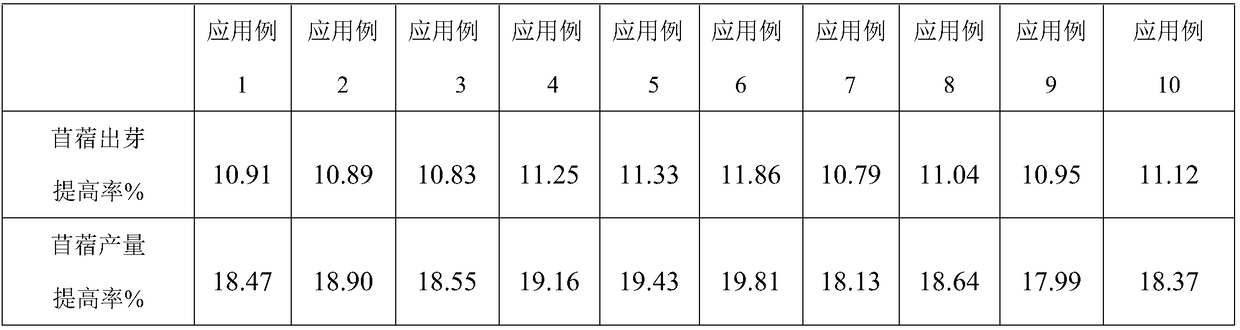

Examples

preparation example Construction

[0027] The preparation method of described coating agent comprises the steps:

[0028] The first step is to add the Sinorhizobium meliloti into the water, stir evenly, and obtain material A;

[0029] The second part adds the urea, the monoammonium phosphate and the polyaspartic acid into the material A, and continues to stir until uniform to obtain the material B;

[0030] The third step is to add the ABT root-inducing powder to the material B, and continue to stir until uniform to obtain material C;

[0031] The fourth step is to add the vinegar grains and the boric acid to the material C, and continue to stir until uniform to obtain the material D;

[0032] The fifth step is to add the water retaining agent and the desalting agent to the material D, and continue to stir until uniform to obtain the material E;

[0033] The sixth step is to add the clay powder and the talc powder to the material E, and continue to stir until uniform to obtain the material F; add the material...

Embodiment 1

[0047] The percentage by weight of each component of the coating agent is: 18% for urea, 13% for monoammonium phosphate, 11% for polyaspartic acid, 7% for Sinorhizobium meliloti, 12% for ABT rooting powder, 12% for vinegar grains 6% for desalination agent, 7% for water retaining agent, 5% for boric acid, 7% for water, 3% for clay powder, and 3% for talcum powder.

[0048] The coating agent is obtained according to the preparation method of the coating agent according to the weight percentage of each component of the coating agent.

[0049] After the alfalfa seeds are coated with the coating agent and planted, the alfalfa germination improvement rate is 11.25%, and the alfalfa yield improvement rate is 19.16%.

Embodiment 2

[0051] The percentages by weight of each component of the coating agent are: 16% for urea, 14% for monoammonium phosphate, 12% for polyaspartic acid, 8% for Sinorhizobium meliloti, 12% for ABT rooting powder, 12% for vinegar grains 8% for desalination agent, 4% for water retaining agent, 6% for boric acid, 5% for water, 3% for clay powder, and 4% for talcum powder.

[0052] The coating agent is obtained according to the preparation method of the coating agent according to the weight percentage of each component of the coating agent.

[0053] After the alfalfa seeds are coated with the coating agent and planted, the alfalfa germination improvement rate is 11.33%, and the alfalfa yield improvement rate is 19.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com