Small environment-friendly energy-saving oil pressing production device

A technology of environmental protection, energy saving and production equipment, which is applied in the production of fat oil/fat and fat production, can solve the problem of high cost of waste gas treatment, and achieve the effect of improving dust removal effect, reducing falling speed, improving dust removal effect and baking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

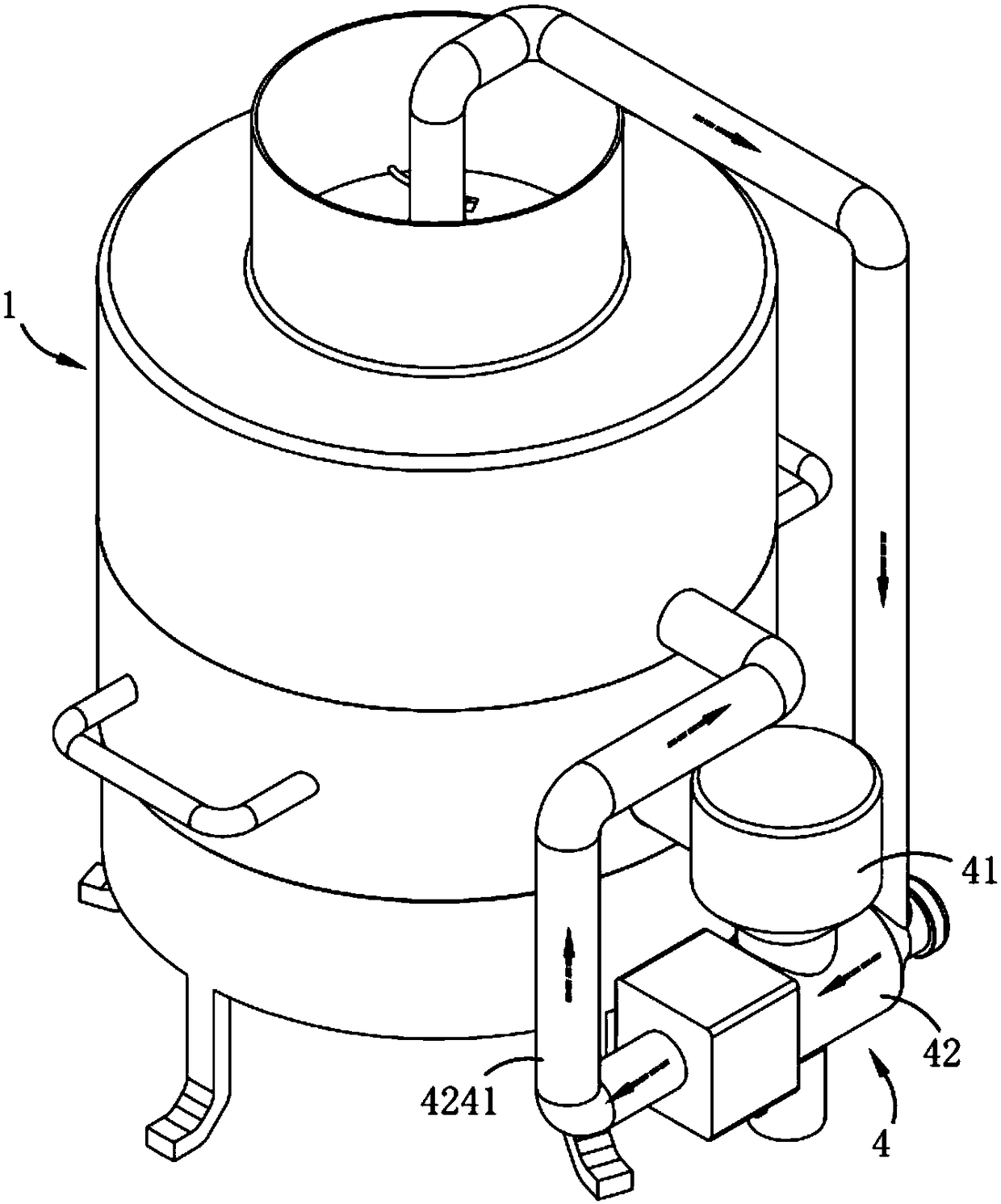

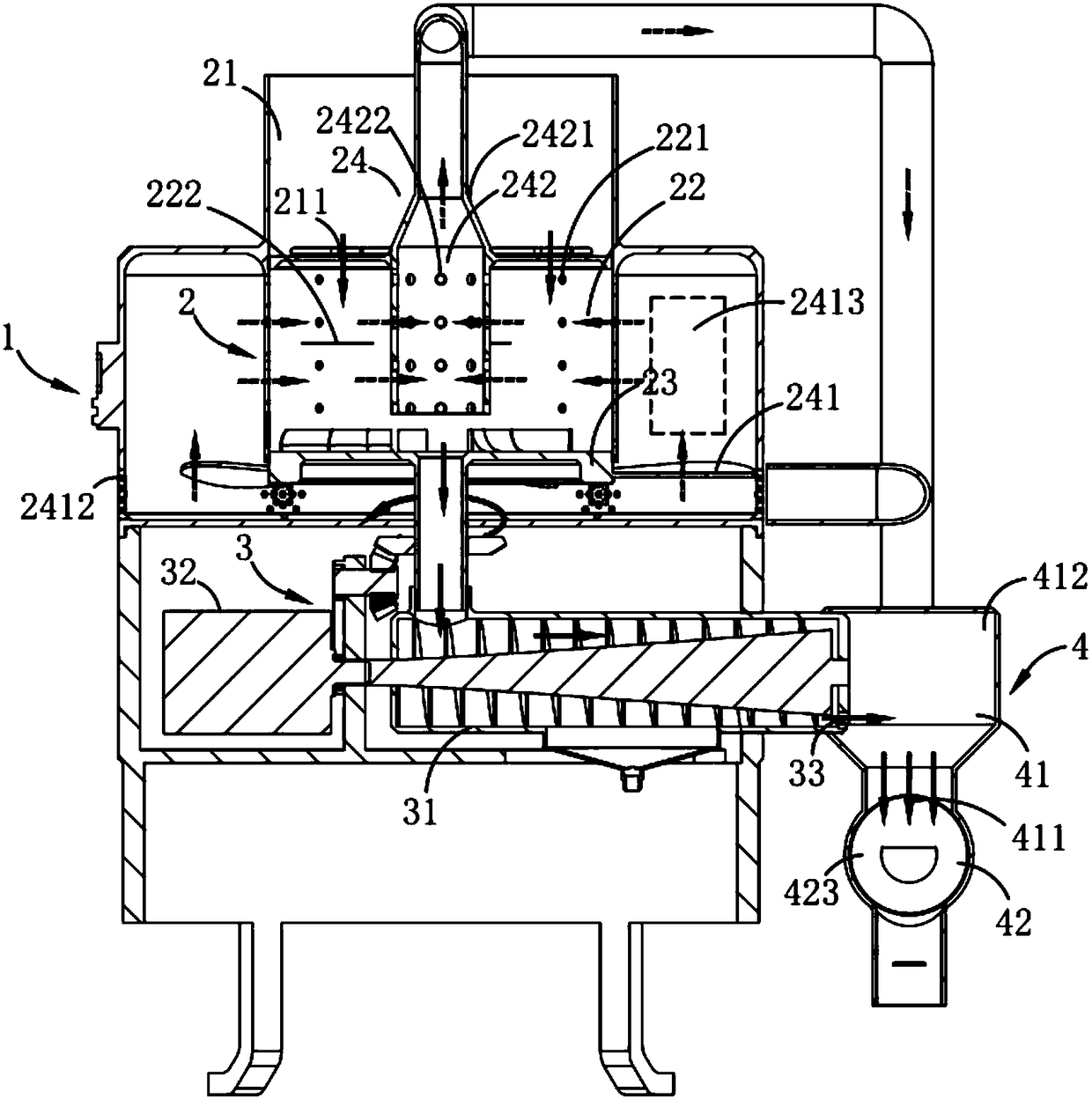

[0036] Such as figure 1 , 2 As shown in and 3, a small-scale environmental protection and energy-saving oil extraction production device includes a heating chamber 1, and also includes:

[0037] Baking mechanism 2; the baking mechanism 2 is arranged inside the heating bin 1, which includes a storage bin 21 for placing oil, a dust removal bin 22 located below the storage bin 21, and a dust removal bin 22 arranged inside the The transmission assembly 23 and the dust removal assembly 24 for cleaning the dust inside the dust remova...

Embodiment 2

[0047] Such as figure 2 with 5 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that: the guide part 323 is fixedly arranged on the baking bin 321 and is located above the transfer part 322, and includes a plurality of elastic pieces 3231 arranged uniformly around the axis of the baking bin 321. The elastic pieces 3231 It is elastically connected to the inner wall of the baking bin 321, and the elastic piece 3231 is arranged at an angle with the inner wall of the baking bin 321; A beveled blade 2411 and an air-introduction hole 2412 opened on the heating chamber 1, the beveled blade 2411 is located in the heating chamber 1 and below the dust removal chamber 22, forming a pressure zone 2413 above it, The a...

Embodiment 3

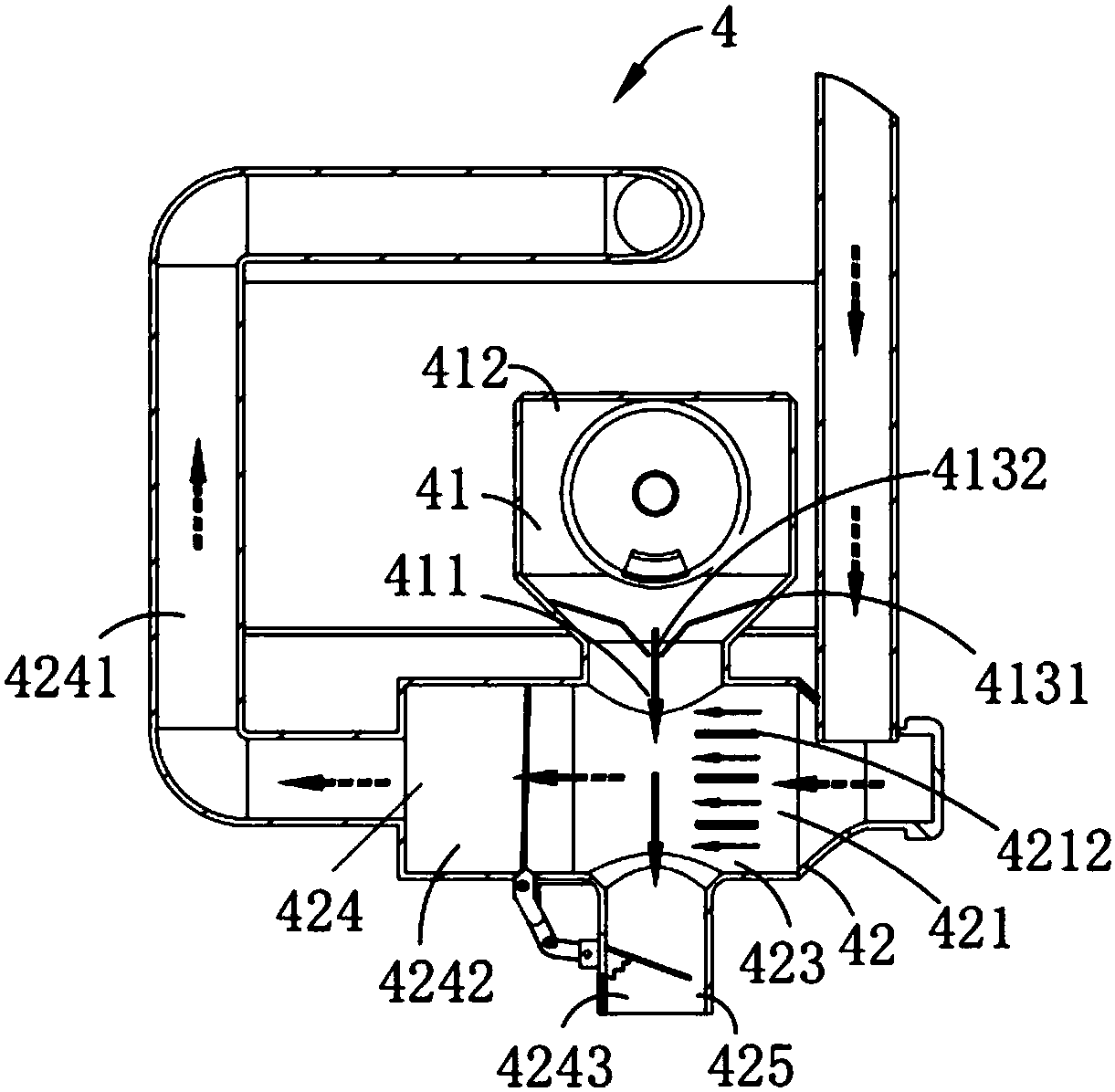

[0051] Such as figure 2 with 3 As shown, the parts identical or corresponding to those in the second embodiment adopt the reference numerals corresponding to the second embodiment. For the sake of simplicity, only the differences between the second embodiment and the second embodiment are described below; the difference between the third embodiment and the second embodiment The difference is that the molding assembly 41 includes a receiving bin 412 fixedly arranged on one side of the outer side of the heating bin 1, and a deflector 413 located at the bottom of the receiving bin, and the deflector 413 includes symmetrically arranged deflectors 4131 , forming a splayed slit 4132 facing upwards, the waste curtain 411 flows downward through the slit 4132; the waste falls on the deflector 4131 and is guided by the slant plate and limited by the width under the double action of it, so that It forms a curtain structure of uniform thickness.

[0052] Further, as figure 2 with 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com