Small environment-friendly energy-saving squeezed oil manufacture production technology

An environmental protection, energy saving, and production process technology, applied in the direction of fat oil/fat production, fat generation, separation methods, etc., can solve the problems of high cost of waste gas treatment, reduce energy consumption, solve the problem of poor uniformity of continuous baking, baking efficiency and heating The effect of uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

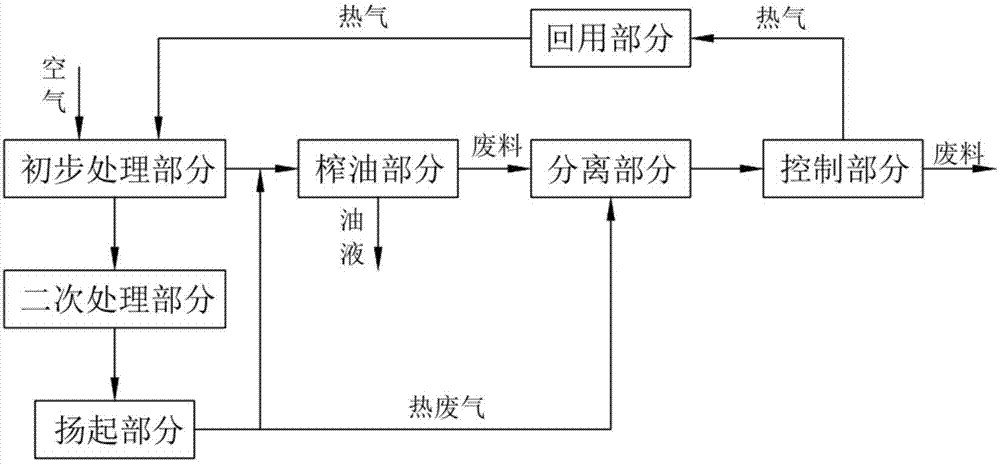

[0034] Reference manual attached figure 1 A small-scale environment-friendly and energy-saving oil extraction production process in this embodiment is described.

[0035] A small-scale environmental protection and energy-saving oil extraction production process is characterized in that it comprises the following steps:

[0036] (a) In the preliminary treatment part, the oil to be treated enters the dust removal chamber 22 and enters the preliminary dust removal station in a free fall manner. The falling oil is sprayed and blown ...

Embodiment 2

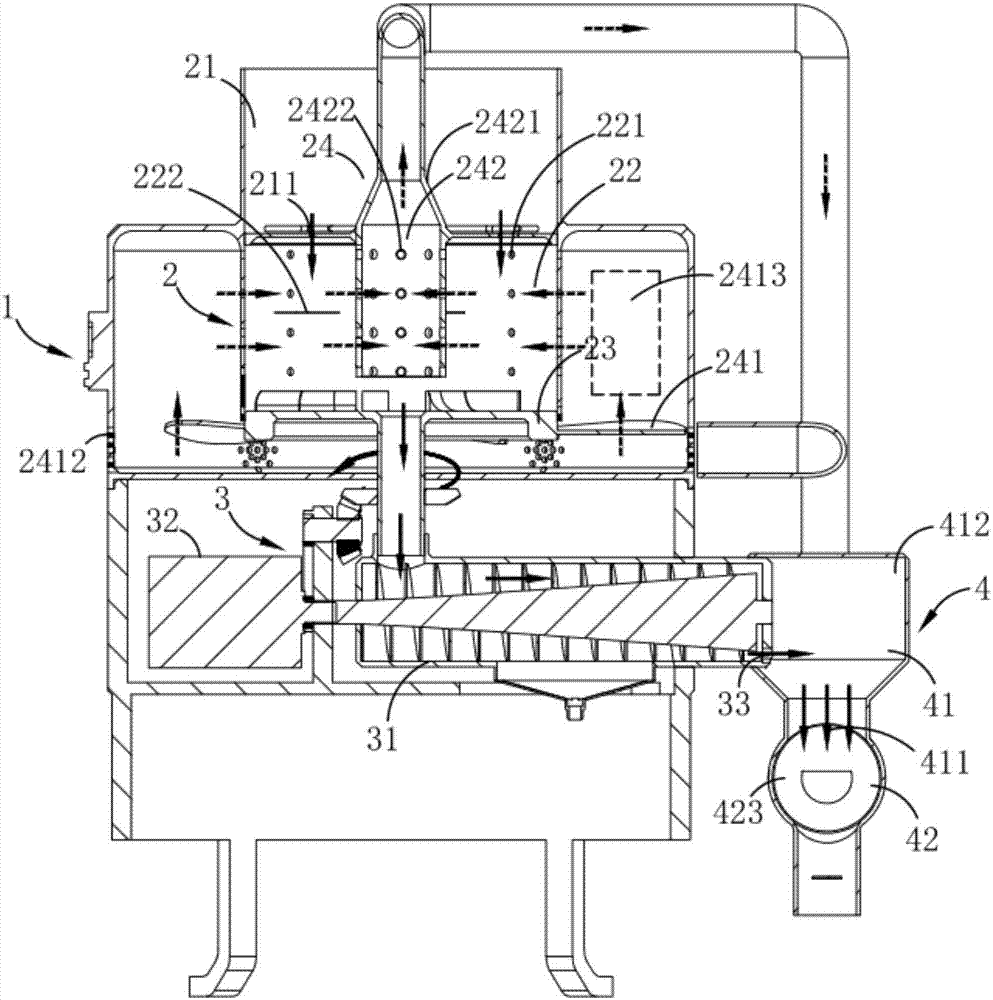

[0046] Wherein, the same or corresponding parts as those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment is that : the waste material curtain 411 is formed by freely falling waste material, after the waste material is flattened by the baffle plate 4131 on the molding assembly 41 in a slanted plate flow manner, the slit 4132 formed by the baffle plate 4131 is symmetrically arranged Positioning is performed, and the waste material flows through the slit 4132 to form a waste material curtain 411 .

[0047] Further, the air curtain 422 divides the diversion region 4211 in the diversion part 421 by a plurality of diverter plates 4212 on the diverter part 421 at intervals up and down, and the exhaust gas flowing through the diversion region 4211 passes through the diverter plat...

Embodiment 3

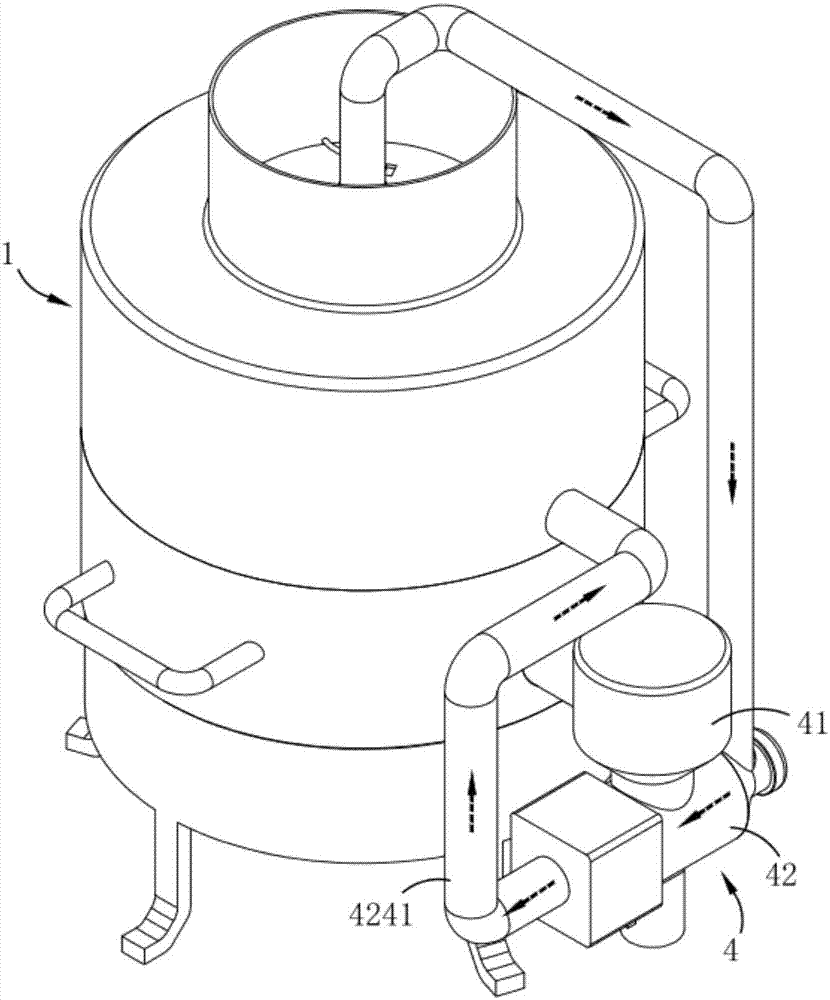

[0052] Refer to the attached Figure 2-8 Describe a small-scale environment-friendly and energy-saving oil extraction production device in this embodiment.

[0053] Such as figure 2 , 3 Shown in and 4, a small-scale environment-friendly and energy-saving oil extraction production device includes a heating chamber 1, and also includes:

[0054] Baking mechanism 2; the baking mechanism 2 is arranged inside the heating bin 1, which includes a storage bin 21 for placing oil, a dust removal bin 22 located below the storage bin 21, and a dust removal bin 22 arranged inside the The transmission assembly 23 and the dust removal assembly 24 for cleaning the dust inside the dust removal bin 22, the dust removal assembly 24 includes a drainage part 241 and an exhaust part 242;

[0055] The oil pressing mechanism 3, the oil after dedusting and roasting is transmitted to the oil pressing mechanism 3 through the transmission component 23, and the oil pressing mechanism 3 includes an oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com