Vascular patch using silk matrix and method of manufacturing same

一种制造方法、基质的技术,应用在利用蚕丝基质的血管补片及其制造领域,能够解决炎症或组织坏死、不可能长时间发挥血管功能、低生物相容性等问题,达到降低制造成本、优异细胞培养能力、简单制造工艺的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Production of the vascular patch 1 of the present invention

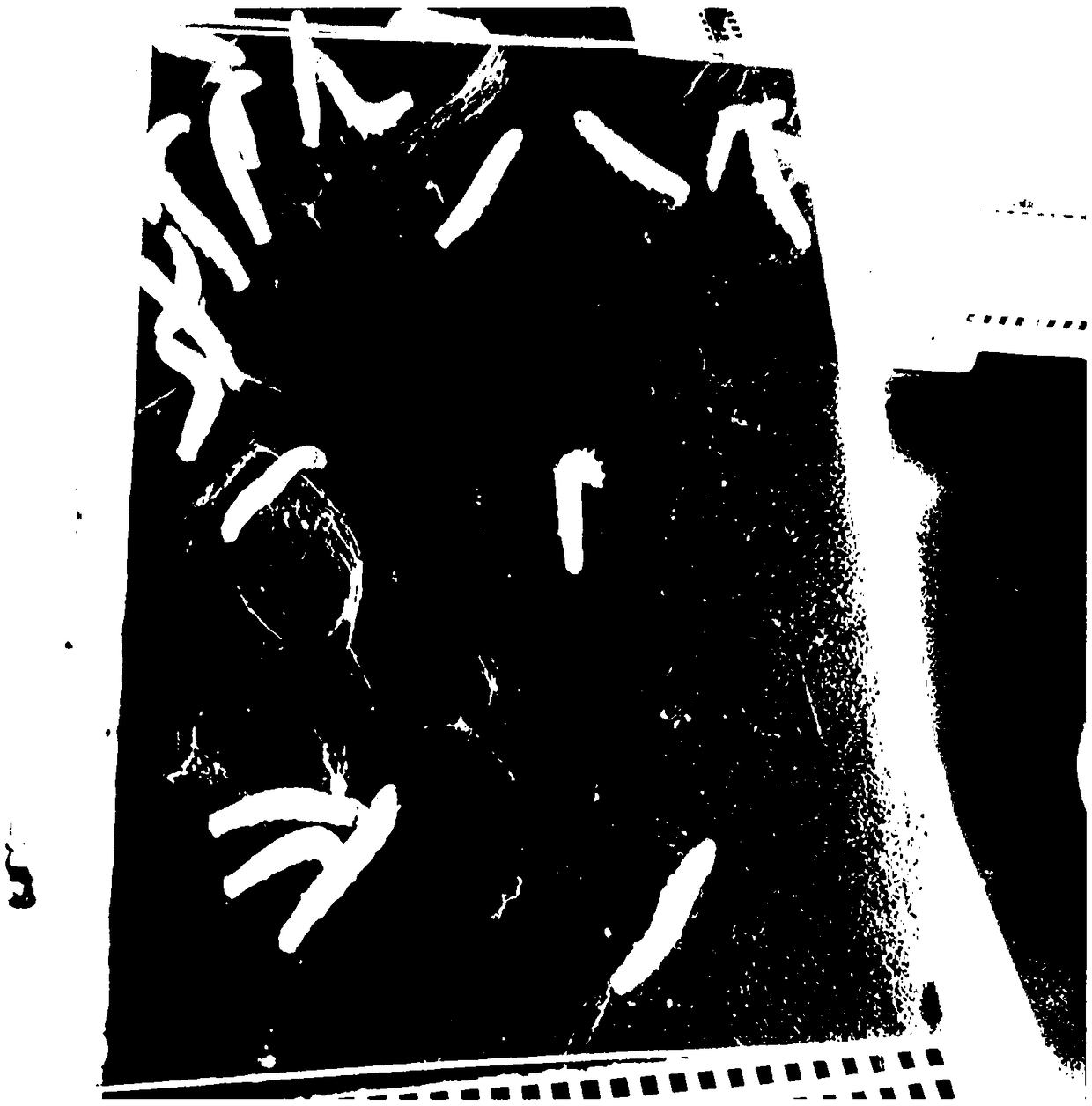

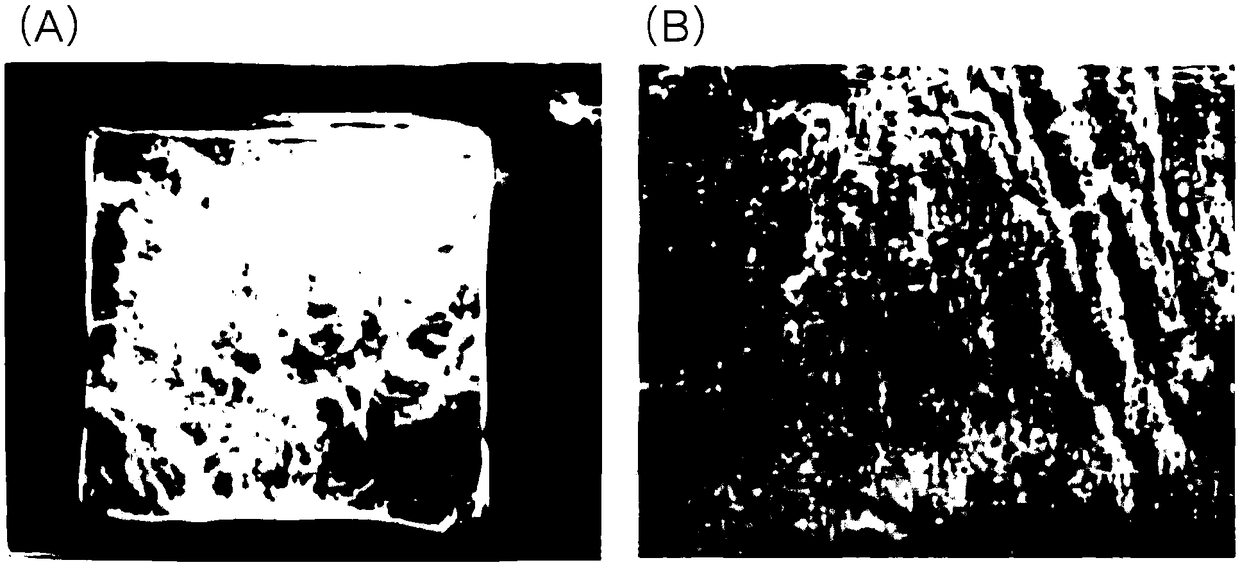

[0058] like figure 1 As shown, 15 mature silkworms were placed on a sheet gradually inclined at 20° relative to the ground. After 1 hour, the sheet was again gradually tilted in the opposite direction. In this way, silkworms weave cocoons while moving, producing figure 2 The silk matrix 10 of the configuration shown in A.

[0059] The above-mentioned tilting process was performed for one day, the balance was maintained for two days, and the above-mentioned tilting process was performed again, whereby silk substrates were produced from silkworms in about 3 days. The thickness of the silk matrix is about 0.01 mm.

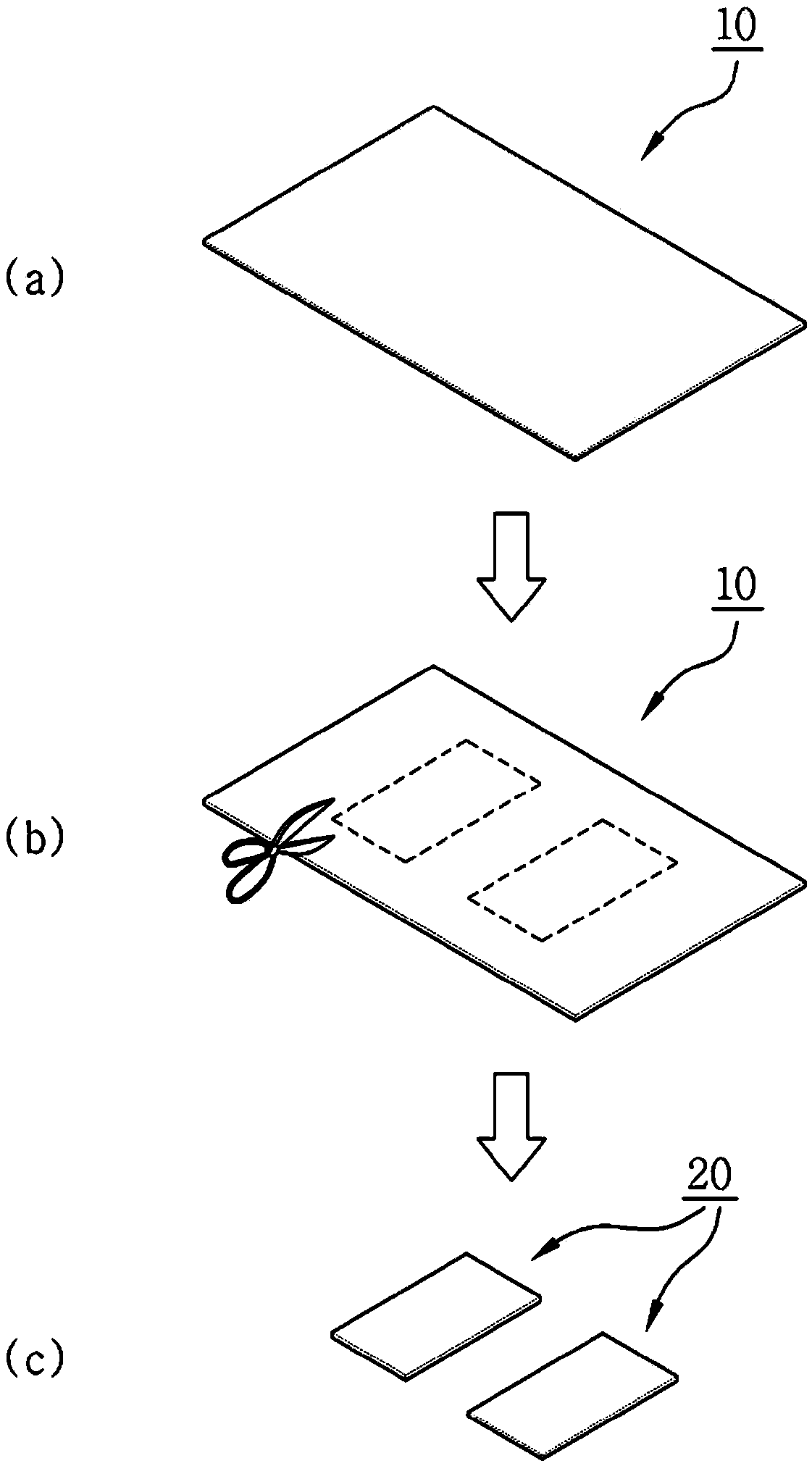

[0060] like image 3 As shown, the silk matrix 10 is cut with scissors to divide it planarly in a rectangular shape, thereby forming a silk matrix sheet 20, which is then sterilized to produce the vascular patch 1 of the present invention.

Embodiment 2

[0061] Production of the vascular patch 2 of the present invention

[0062] like figure 1 As shown, 30 mature silkworms were placed on a sheet gradually inclined at 20° relative to the ground. After 1 hour, the sheet was again gradually tilted in the opposite direction. In this way, silkworms weave cocoons while moving, producing figure 2 The silk matrix 10 of the configuration shown in B.

[0063] The above-mentioned tilting process was performed for one day, the balance was maintained for two days, and the above-mentioned tilting process was performed again, whereby silk substrates were produced from silkworms in about 3 days. The thickness of the silk matrix is about 0.7 mm.

[0064] like Figure 4 As shown, the silk matrix 10 with a thickness of 0.7 mm is peeled off to perform thickness division, thereby forming a silk matrix part 30 with a thickness of 0.2 mm, which is then sterilized, thereby producing the vascular patch 2 of the present invention .

Embodiment 3

[0065] Production of the vascular patch 3 of the present invention

[0066] like figure 1 As shown, 30 mature silkworms were placed on the sheet, and the sheet was gradually inclined at 20° relative to the ground. After 1 hour, the sheet was again gradually tilted in the opposite direction. In this way, silkworms weave cocoons while moving, producing figure 2 The silk matrix 10 of the configuration shown in B.

[0067] The above-mentioned tilting process was performed for one day, the balance was maintained for two days, and the above-mentioned tilting process was performed again, whereby silk substrates were produced from silkworms in about 3 days. The thickness of the silk matrix is about 0.7mm.

[0068] The silk matrix is then cut so as to be planarly divided in a rectangular shape, whereby the silk matrix sheet 20 is formed.

[0069] like Figure 5 As shown, the silk matrix sheet 20 with a thickness of 0.7 mm was peeled off to perform thickness division, ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com