Method for recovering ethylene and vinyl-based comonomer

A comonomer and vinyl technology, which is applied in the field of recycling ethylene and vinyl-based comonomers, can solve the problems of high cost, consumption, and insufficient recycling, and achieve the effect of cost minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

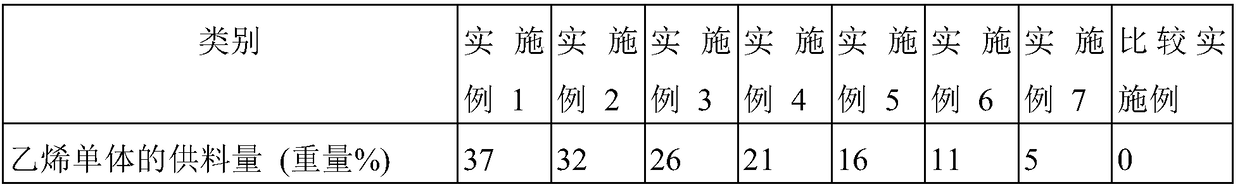

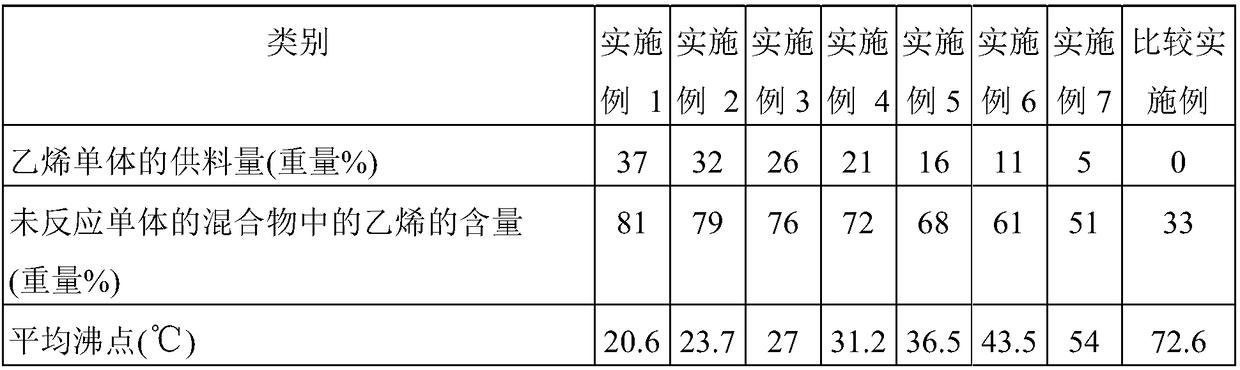

Embodiment 1 to 7

[0056]

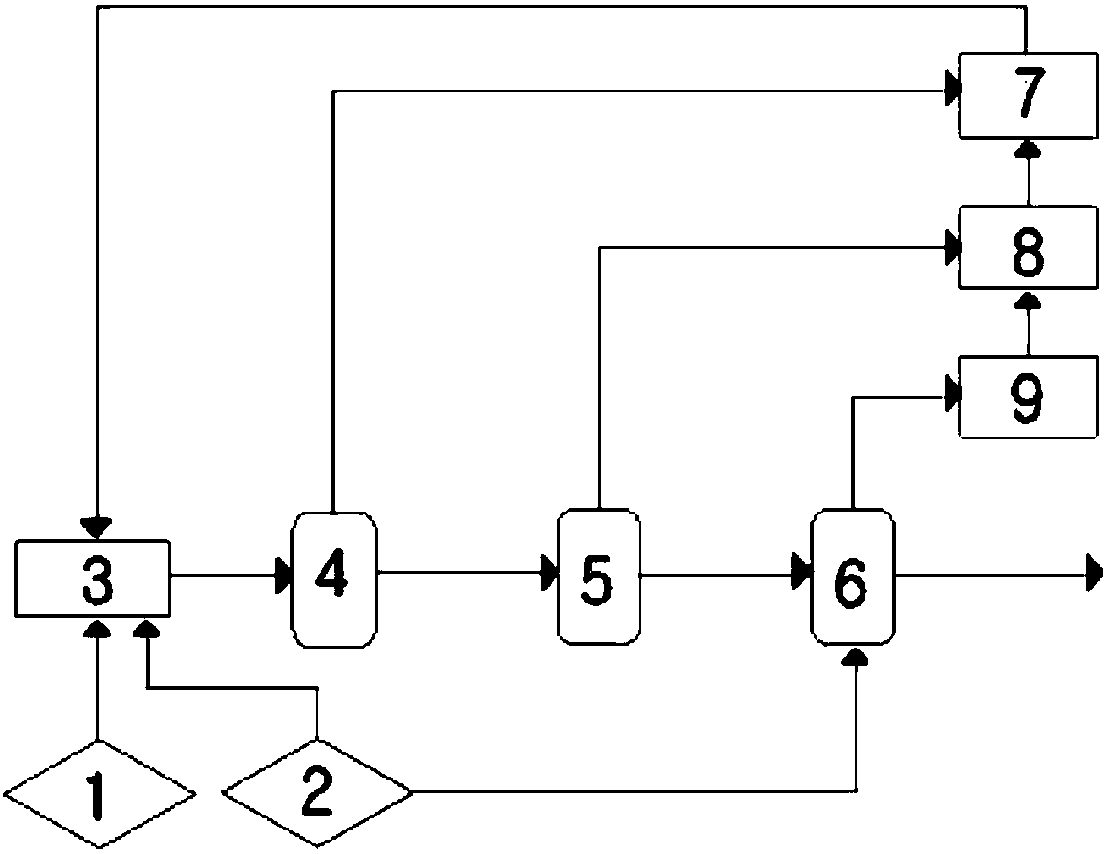

[0057] refer to figure 1 , Vinyl acetate monomer from vessel 1 and ethylene monomer from vessel 2 were respectively fed into reactor 3 at a temperature of about 150° C. to 250° C. and a pressure of 2000 bar for radical polymerization. After the reaction is complete, the mixture of ethylene-vinyl acetate polymer and unreacted monomers in the reactor 3 is transferred to the first separator 4 at a temperature of about 200°C to 250°C and a pressure of 250 bar.

[0058] In the first separator 4, the mixture of unreacted monomers is separated in a gaseous state in the upper part of the first separator 4, and the mixture of ethylene-vinyl acetate polymer and some unreacted monomers is separated in the lower part of the first separator 4 Separated in liquid phase. The mixture of unreacted monomers separated in the upper part of the first separator 4 was compressed to a pressure of 2000 bar by the first compressor 7 having a pressure of 250 bar, and then polymerized in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com