cutting device

A technology of cutting device and spindle, applied to the spindle of the workstation and the field of ring spinning machine, can solve the problems of injury to the operator, high injury and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

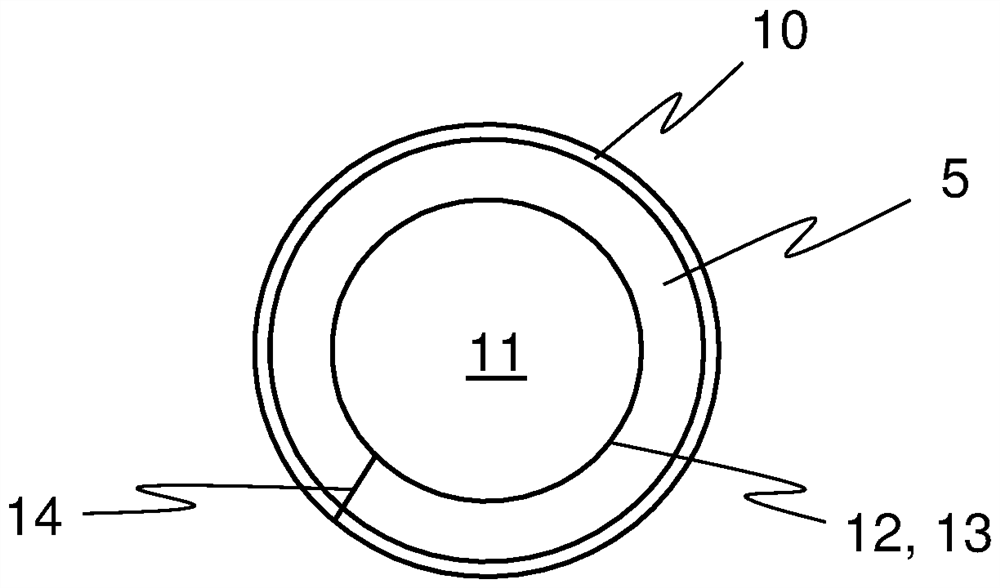

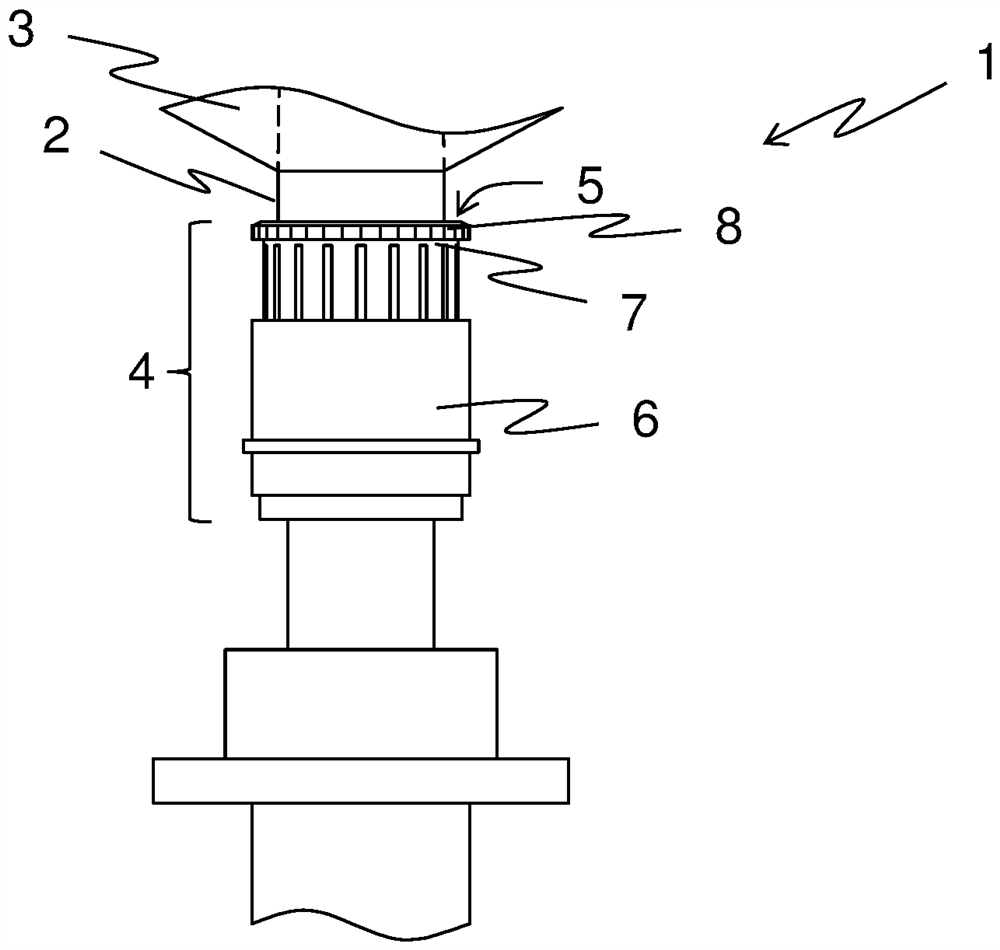

[0038] figure 1 A side view of the spindle 1 is shown. The cop 3 is located on the shaft 2 of the spindle 1 . Adjacent to the shaft 2 of the spindle 1 there is a clamping crown 4 . In addition, the cutting device 5 separate from the clamping crown is arranged on the clamping crown 4 , although hardly visible here, but designed to be flat and located on the clamping crown 4 . Cutting means, cutting edges, etc. are suitable as cutting means 5, as described in the examples below.

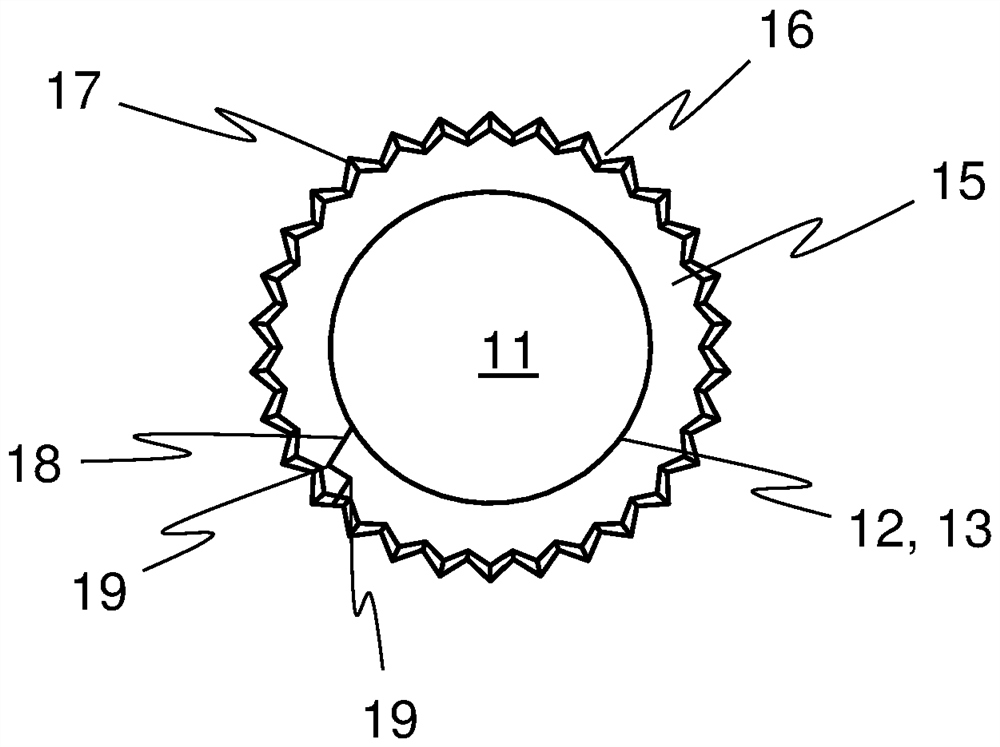

[0039] Figure 2a The clamping crown 4 is shown in more detail in the open state, as it appears shortly before the cop 3 is removed from the spindle 1 . The clamping sleeve 6 has been pulled down in the process, so that the lower winding area 7 is opened. Then, several turns of wire are wound onto the lower winding area 7 . Between the cop 3 and the lower winding area 7 , the thread travels through the notch in the clamping ring 8 and thus also over the cutting device 5 .

[0040] Then, as in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com