Dry gas filter

A filter and dry gas technology, which is applied in the fields of dispersed particle filtration, gas fuel, chemical instruments and methods, etc., can solve the problem of not being suitable for dry natural gas filtration, etc., and achieve the effect of convenient replacement and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

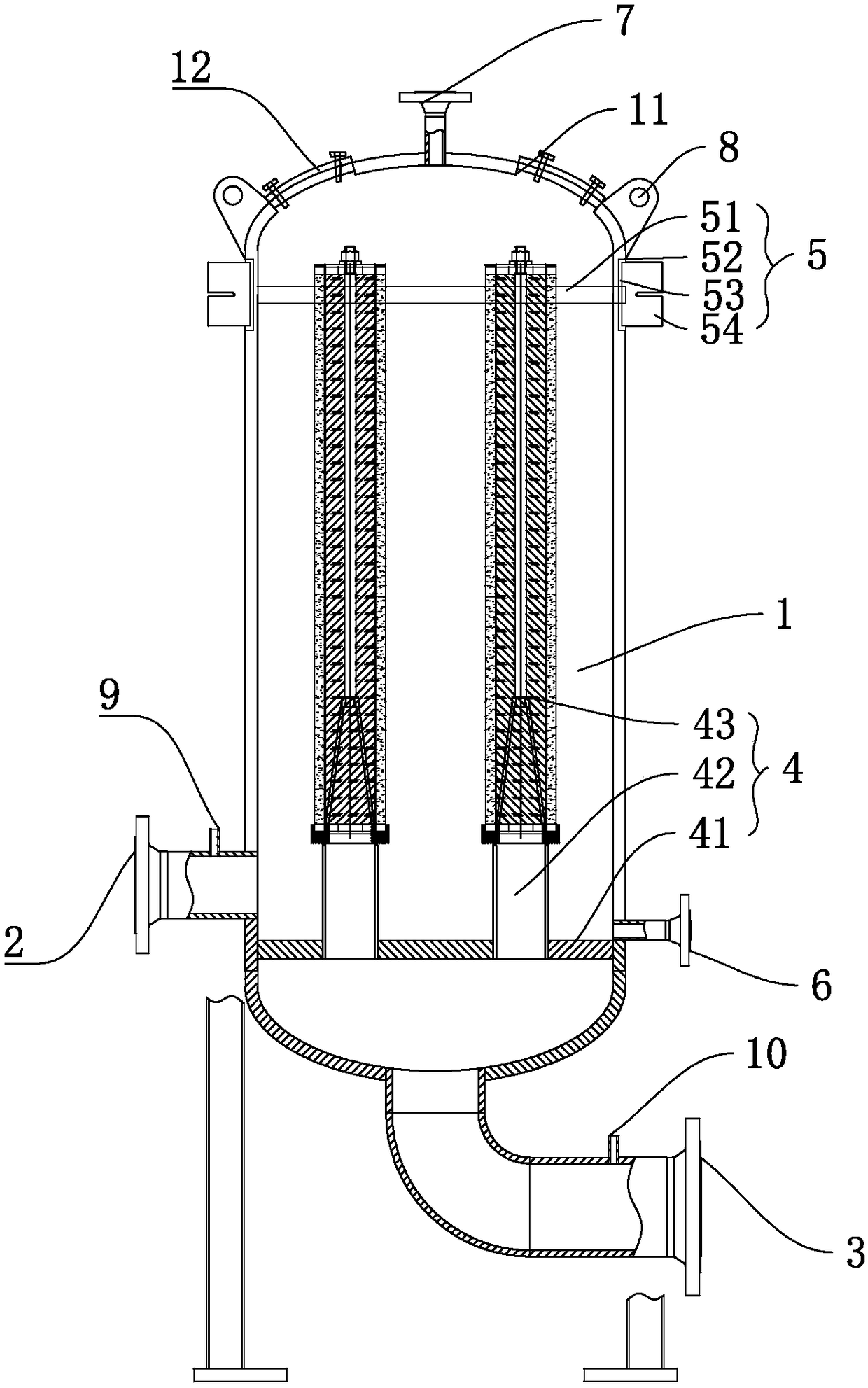

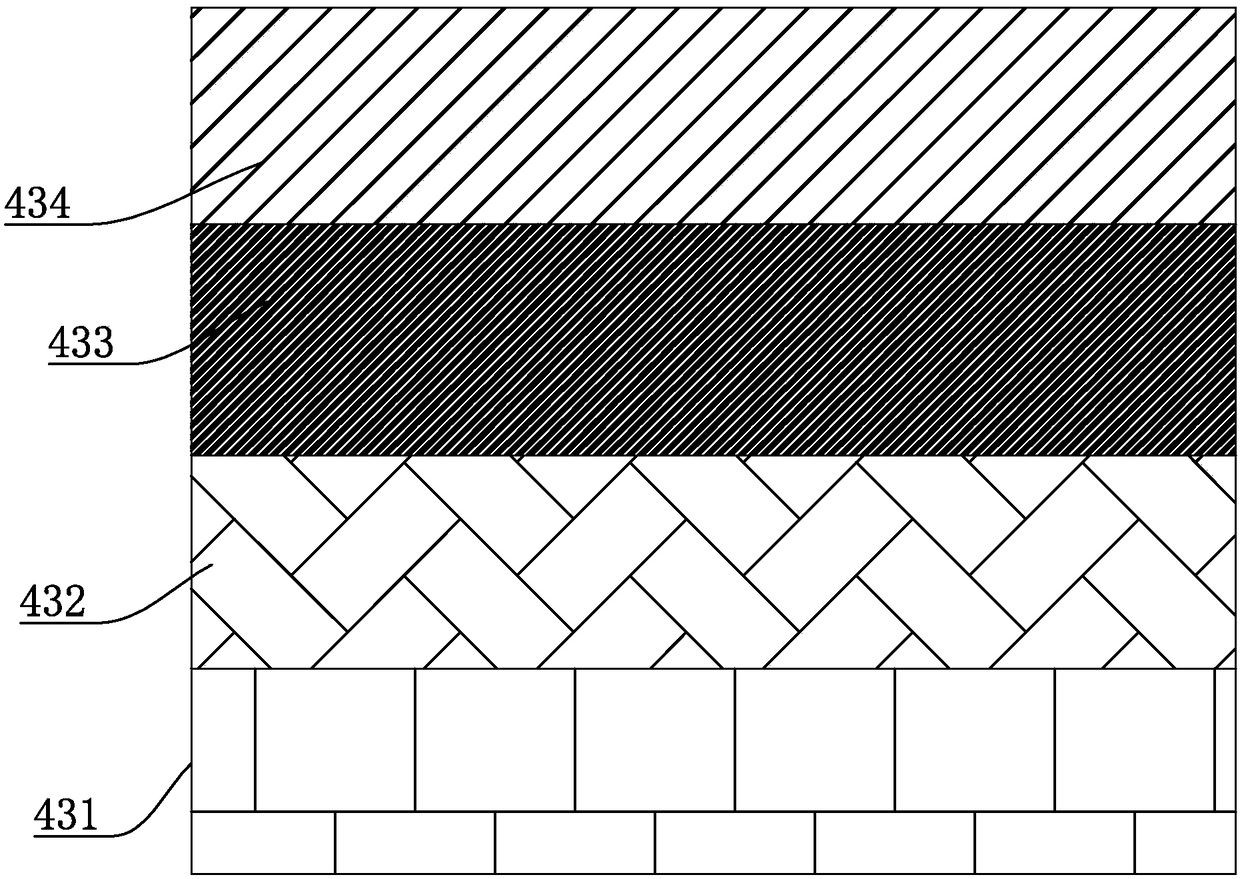

[0027] Example 1: A dry gas filter, such as figure 1 and figure 2 As shown, the tank body 1 is included. The bottom side of the tank body 1 is provided with an air inlet 2; the bottom end of the tank body 1 is provided with an exhaust pipe 3; the air inlet 2 is provided with an inlet pressure gauge 9. An outlet pressure gauge 10 is provided on the exhaust pipe 3, and a filter device 4 is provided in the tank body 1. The filter device 4 includes a support plate 41 located below the air inlet 2 and fixed on the inner wall of the tank body 1. A sewage pipe 6 communicating with the outside of the tank body 1 is provided, a vent pipe 42 is vertically provided on the support plate 41, and the vent pipe 42 penetrates the support plate 41 and communicates with the exhaust pipe 3. At the same time, a filter element 43 is sleeved on the vent pipe 42, and the filter element 43 mainly includes a filter element 43 plate surrounded by a tube and sleeved on the vent pipe 42. The surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com