A method for rolling ultra-thin foil with pulse current assisted multi-roll mill

A pulsed current, rolling mill technology, applied in metal rolling and other directions, can solve the problems of difficulty in insulating multi-roll mills, increasing the frequency of roll change and roll repair, and difficulty in insulating rolling mill equipment, etc., to overcome the energy potential. barrier, improving diffusion capacity, and the effect of fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

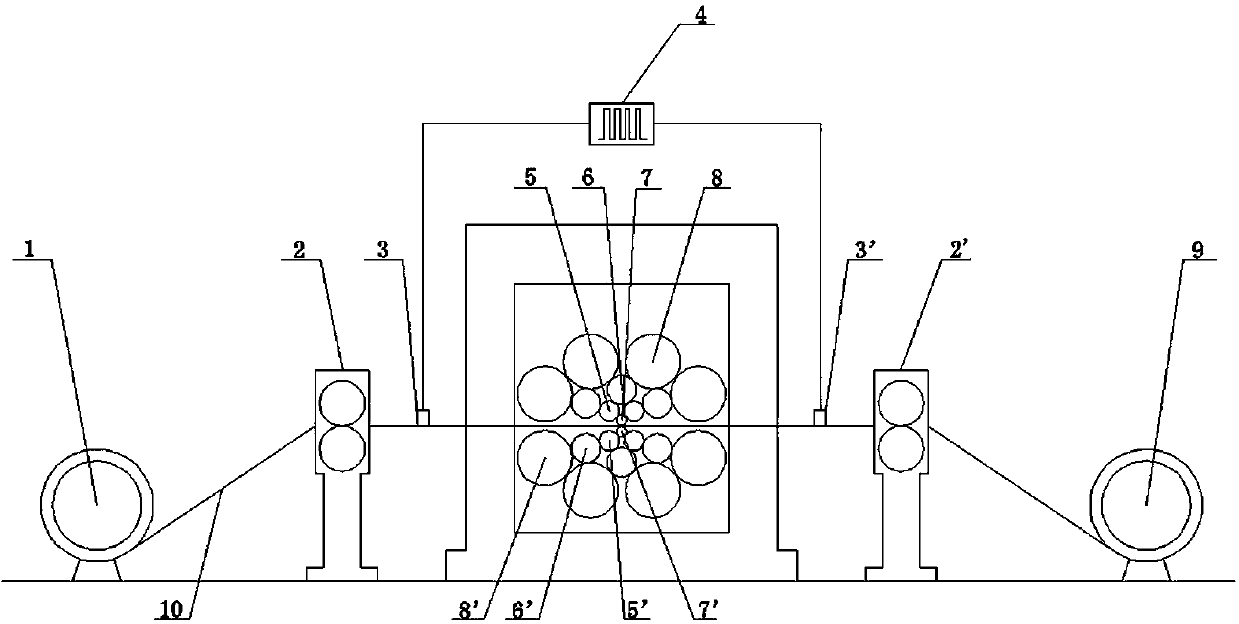

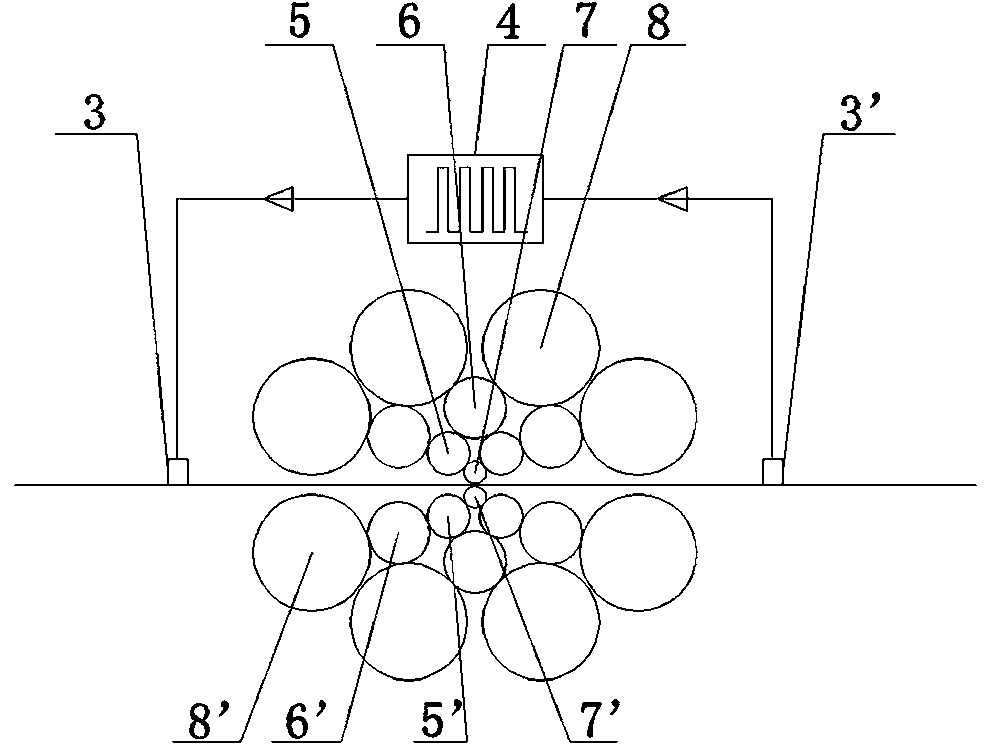

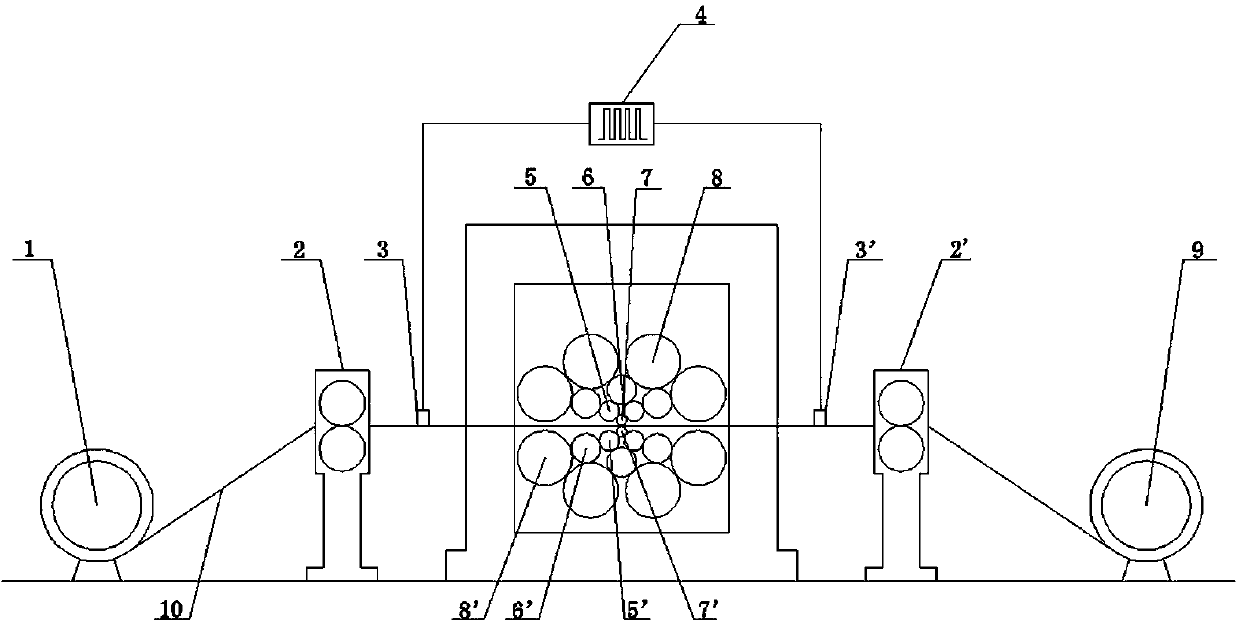

[0034]Referring to Fig. 1 to Fig. 2, take the experiment of rolling 304 stainless steel ultra-thin foil strip with ceramic work rolls in a 20-high rolling mill as an example, including unwinder 1, winder 9, first guide roll 2 and second guide roll 2' , a pair of asynchronously rotating upper and lower roll sets are arranged between the first guide roll 2 and the second guide roll 2', the upper roll set and the lower roll set are respectively composed of four outermost support rolls (four uppermost outermost layer support rollers 8, four lowermost outermost layer support rollers 8'), three second layer intermediate rollers (upper second layer intermediate roller 6, lower second layer intermediate roller 6'), two The first intermediate roll (upper first intermediate roll 5, lower first intermediate roll 5') and one work roll (upper work roll 7, lower work roll 7') are symmetrically arranged, with two upper and lower work rolls (The upper work roll 7, the lower work roll 7') are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com