Drum-type shot blasting machine

A shot blasting machine and drum-type technology, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, explosion generating devices, etc., can solve the problems of large damage to the projectile, affecting the separation effect, and easy blockage of the screen holes, etc., and achieve structural Optimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

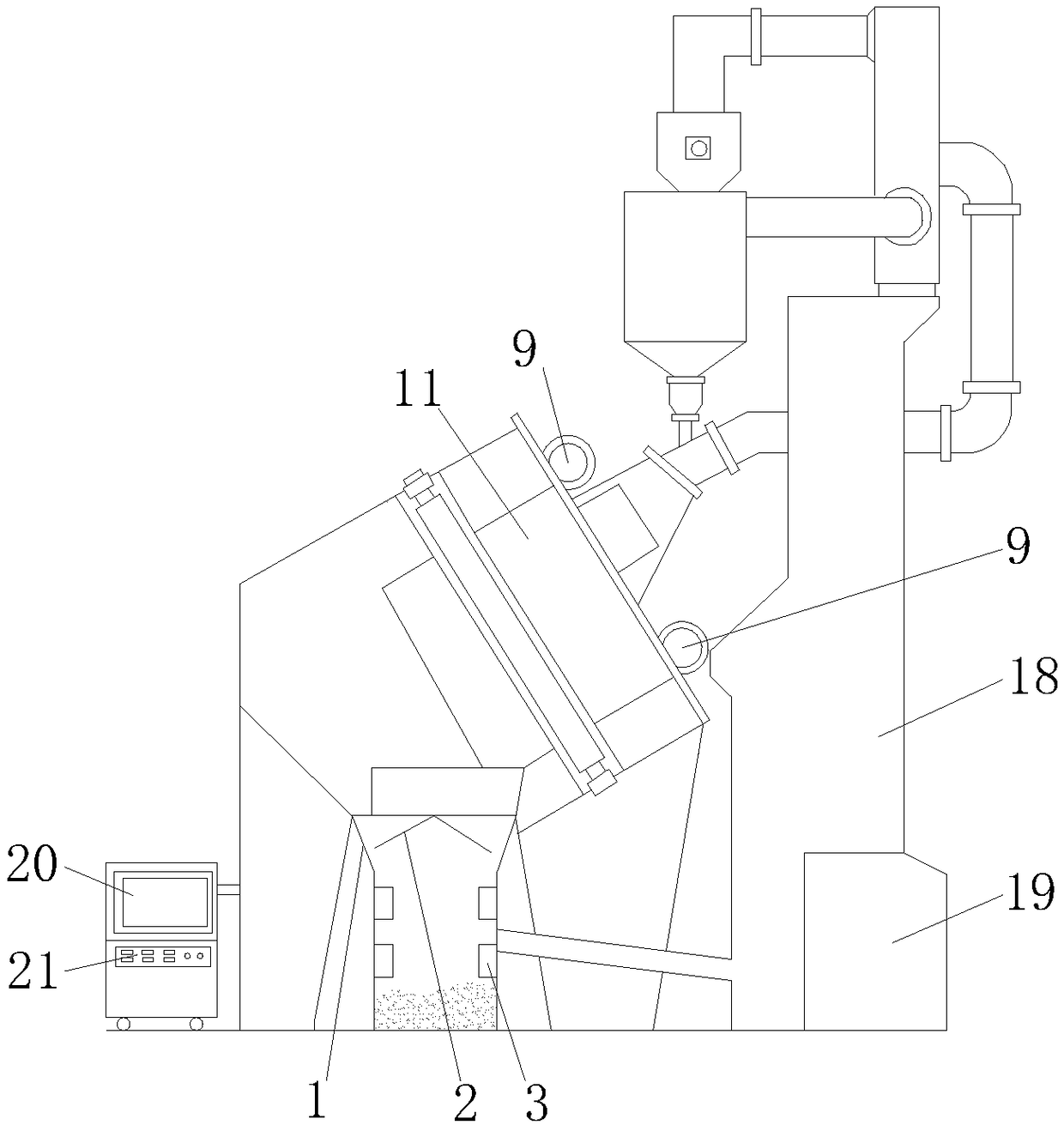

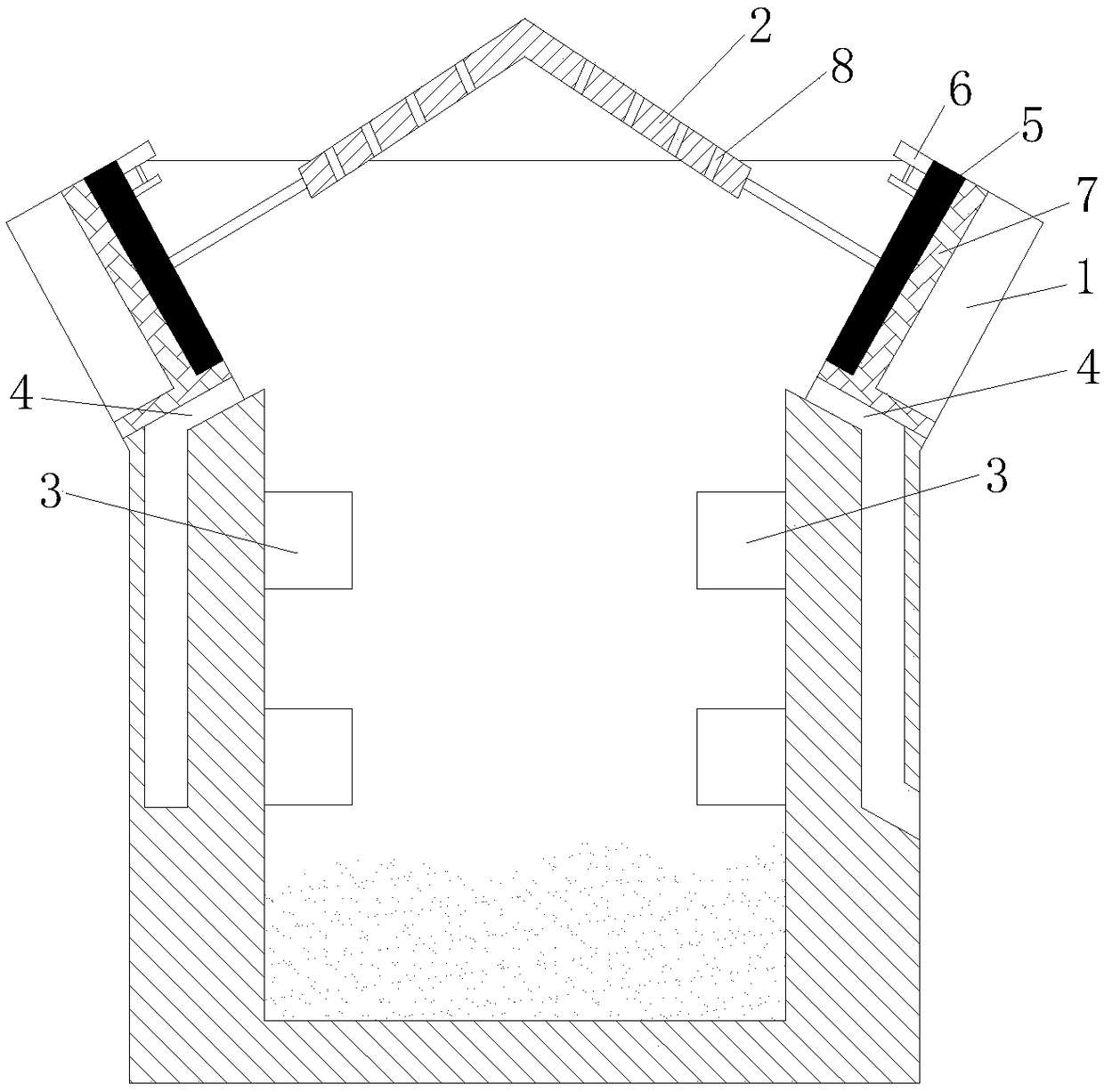

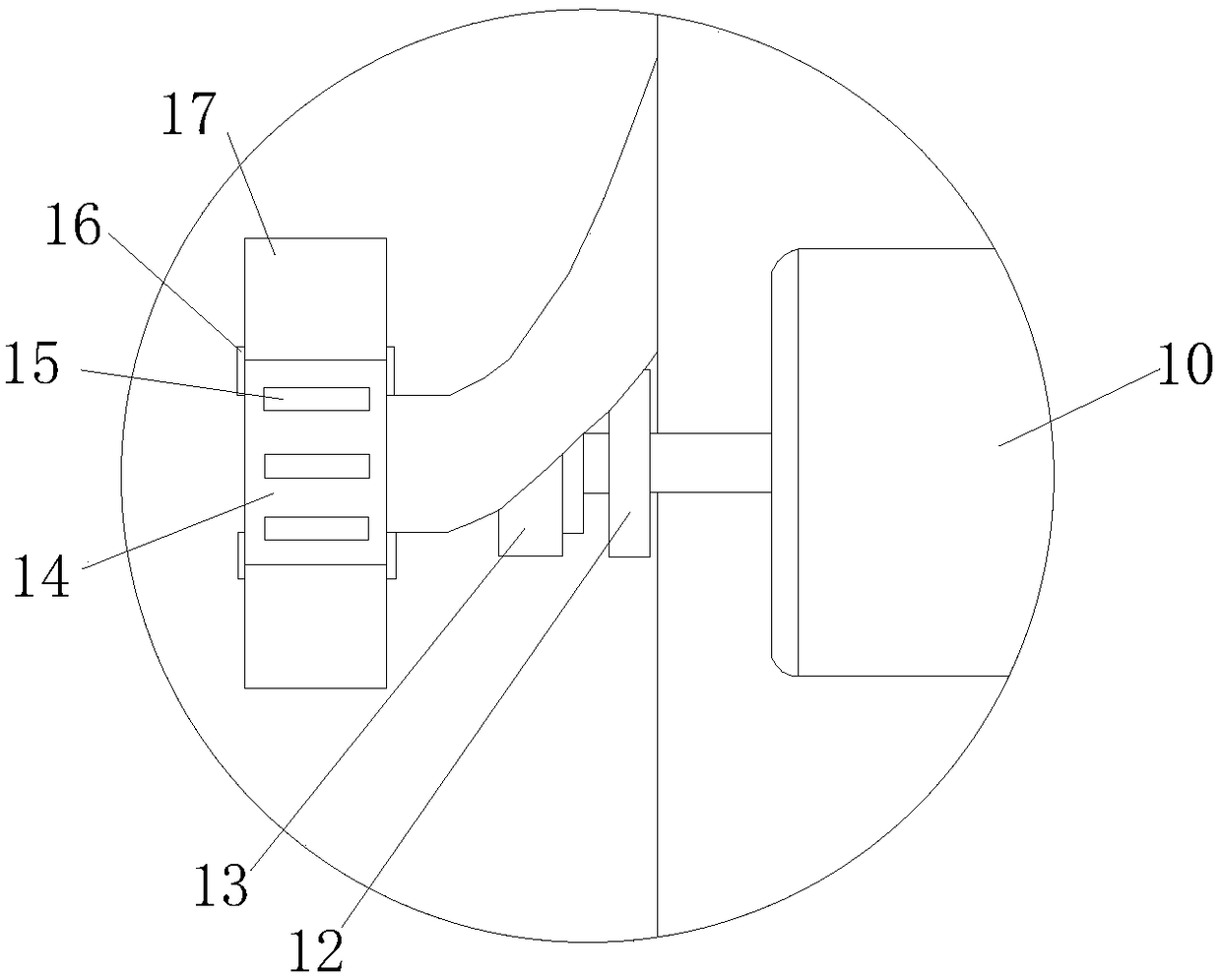

[0022] combined with the above Figure 1 to Figure 3 As shown, the invention discloses a drum type shot blasting machine, which includes a shot blasting unit, a cleaning unit, a shot feeding unit and a control unit. The control unit is arranged on one side of the shot blasting unit, and includes a control panel 20 and a display panel 21 arranged on the control panel 20 . The operator can adjust and set the working parameters of the drum type shot blasting machine of the present invention through the control panel 20, and directly and effectively display and monitor the working status of the drum type shot blasting machine through the display panel 21.

[0023] The inlet end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com