Sterilizing and deodorizing device and machine tool cutting fluid treating device

A treatment device and cutting fluid technology, applied in the direction of filtration treatment, water/sewage treatment, light water/sewage treatment, etc., can solve the problems of high cost and inconvenient, achieve the effect of easy replacement and installation, and improved catalytic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

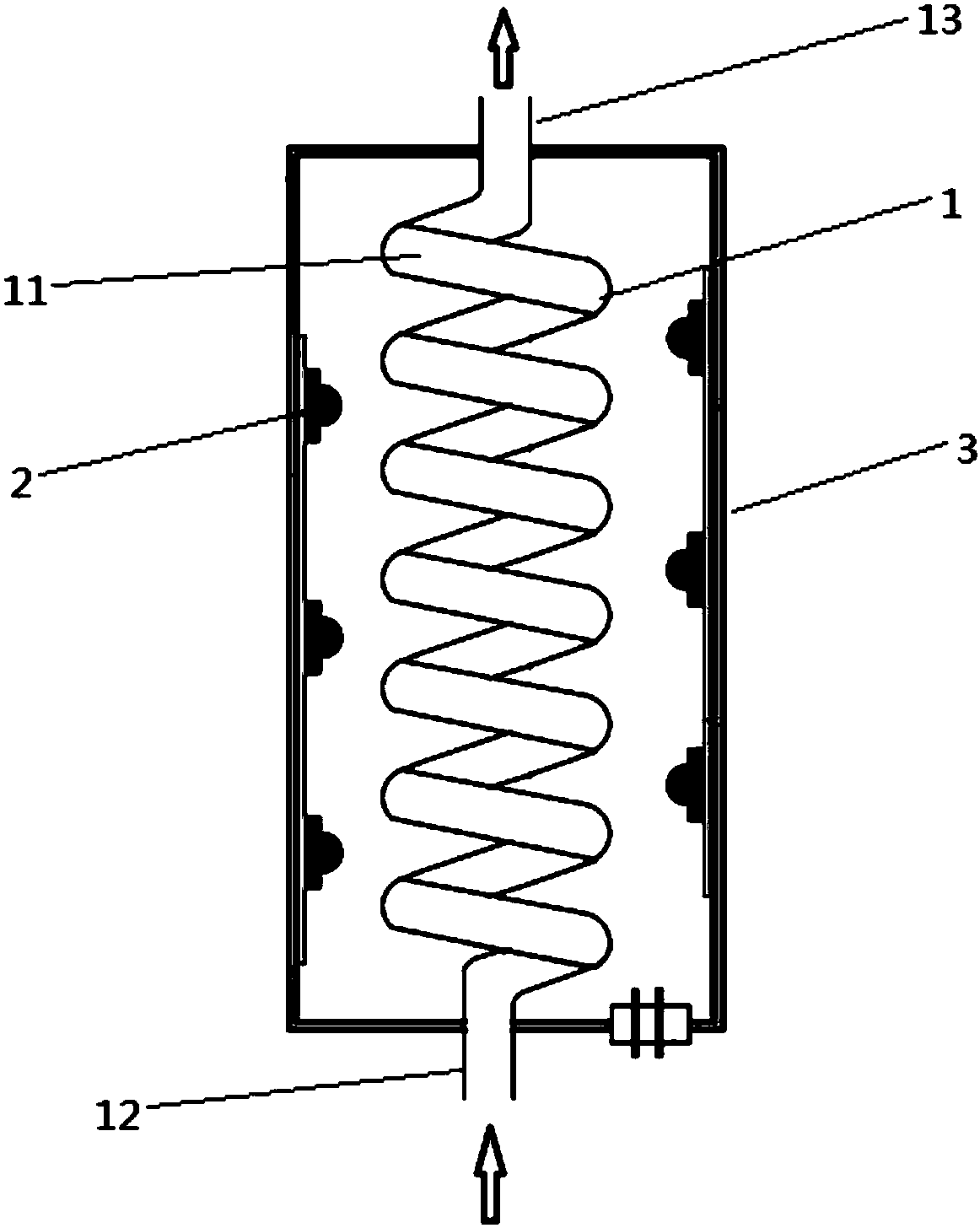

Embodiment 1

[0050] This embodiment provides a machine tool cutting fluid processing device, which includes a machine tool and a cutting fluid circulation pipeline connected to the machine tool, wherein: the machine tool cutting fluid processing device also includes a sterilizing and deodorizing device, and the sterilizing and deodorizing device is arranged on the cutting on the liquid circulation line. In the present invention, a sterilizing and deodorizing device is arranged in series on the cutting fluid circulation pipeline connected to the machine tool to realize the online and timely processing of the cutting fluid, avoiding the shortage of replacing the cutting fluid or using the cutting fluid with deodorant added; in addition, the sterilization and deodorization The device is only installed on the cutting fluid circulation pipeline outside the machine tool, so it is extremely convenient to replace and install without making adaptive changes inside the machine tool, which is extremel...

Embodiment 2

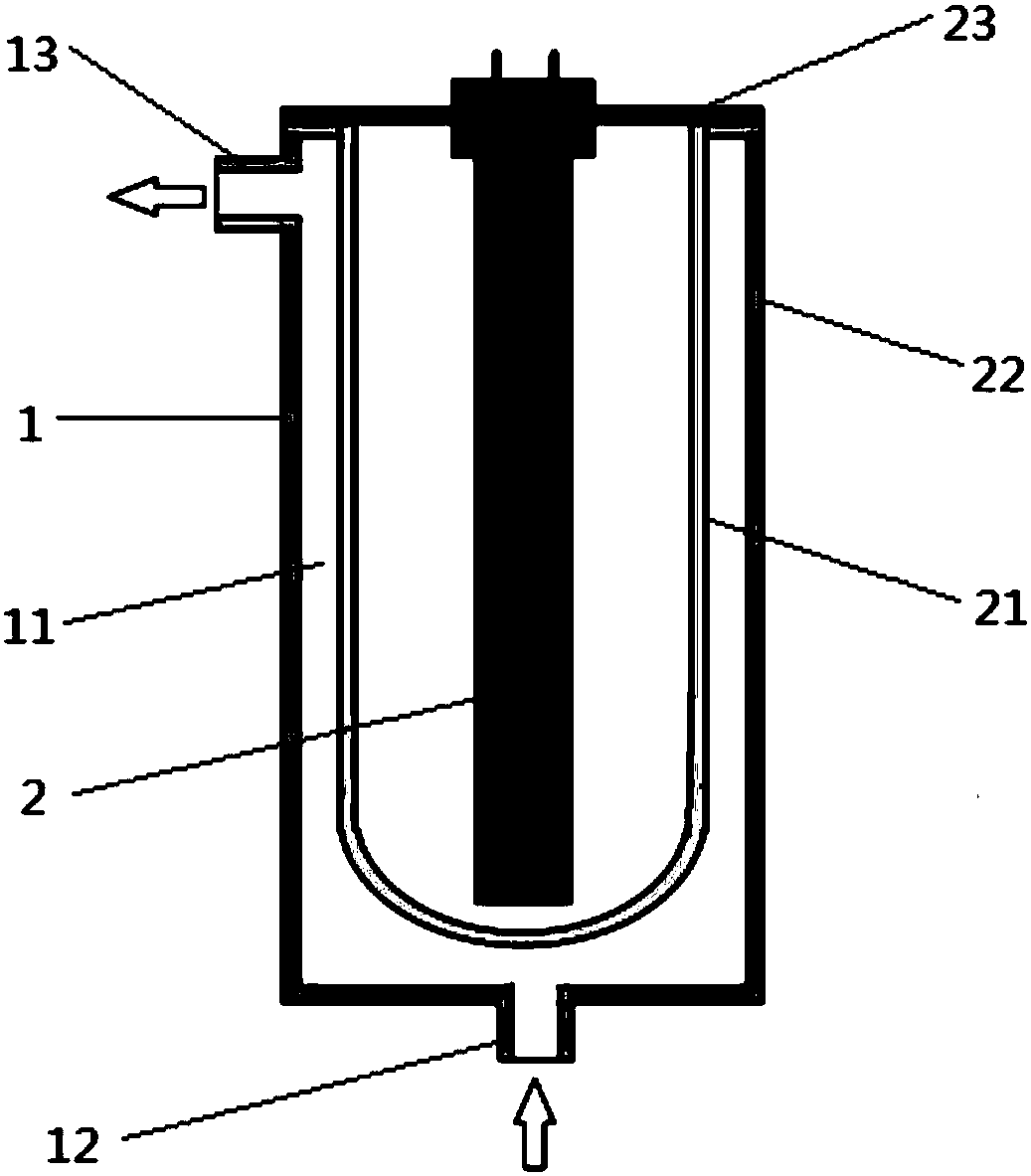

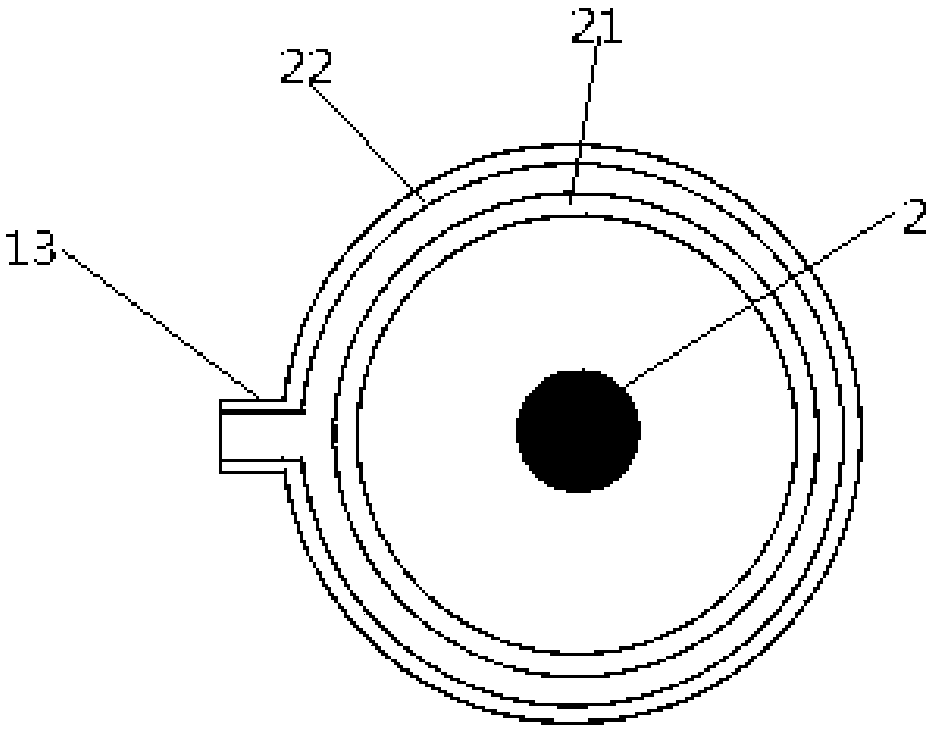

[0066] This embodiment provides a machine tool cutting fluid processing device, which includes a machine tool and a cutting fluid circulation pipeline connected to the machine tool, wherein: the machine tool cutting fluid processing device also includes a sterilizing and deodorizing device, and the sterilizing and deodorizing device is arranged on the cutting on the liquid circulation line. In the present invention, a sterilizing and deodorizing device is arranged in series on the cutting fluid circulation pipeline connected to the machine tool to realize the online and timely processing of the cutting fluid, avoiding the shortage of replacing the cutting fluid or using the cutting fluid with deodorant added; in addition, the sterilization and deodorization The device is only installed on the cutting fluid circulation pipeline outside the machine tool, so it is extremely convenient to replace and install without making adaptive changes inside the machine tool, which is extremel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com