All-aluminum slab-wall structure

A technology for wall panels and aluminum panels, which is applied in the field of all-aluminum panel structures, can solve the problems of non-recyclability, harm, excessive formaldehyde, etc., and achieve the effects of simple structure, strong operability, and reduced installation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

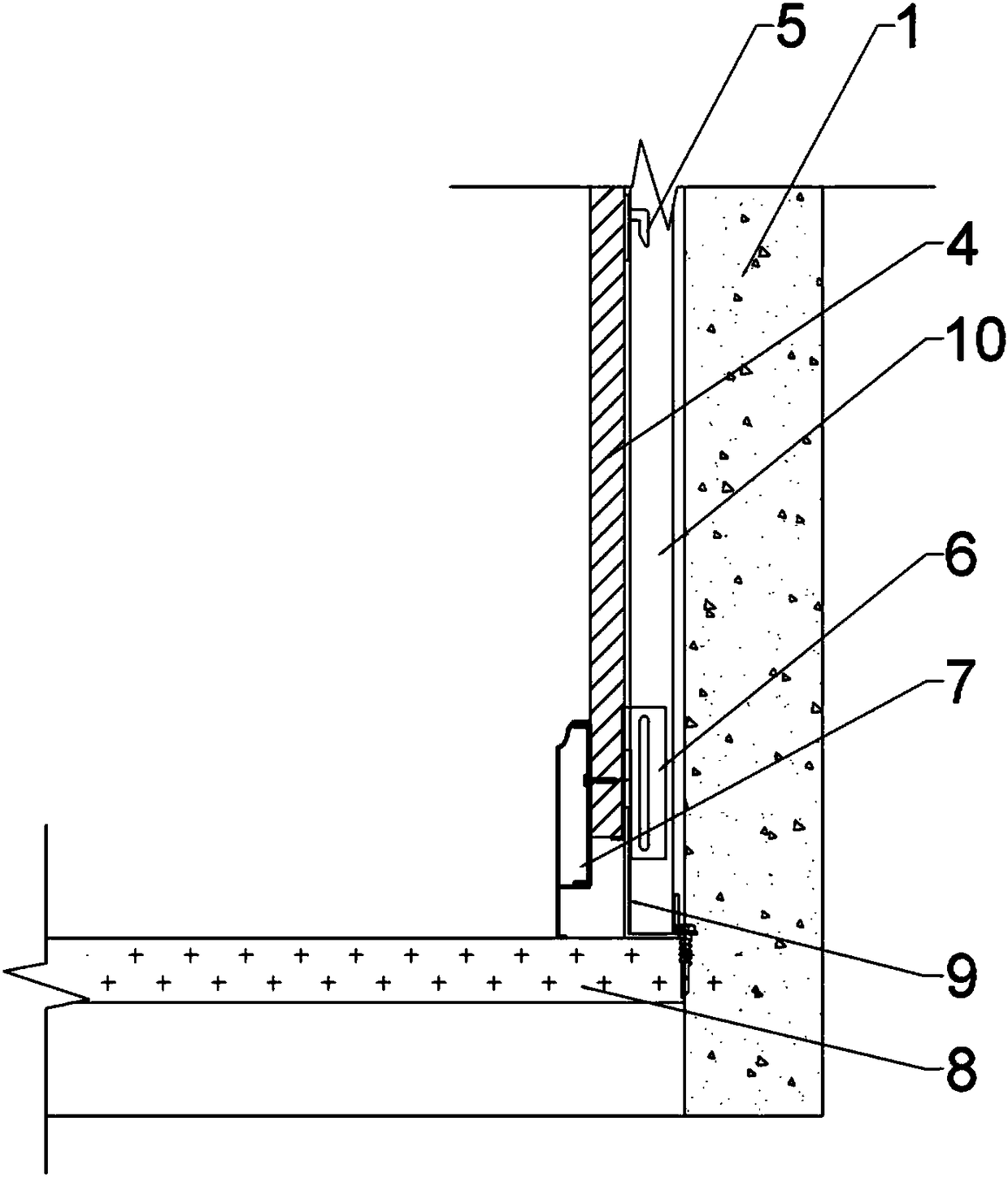

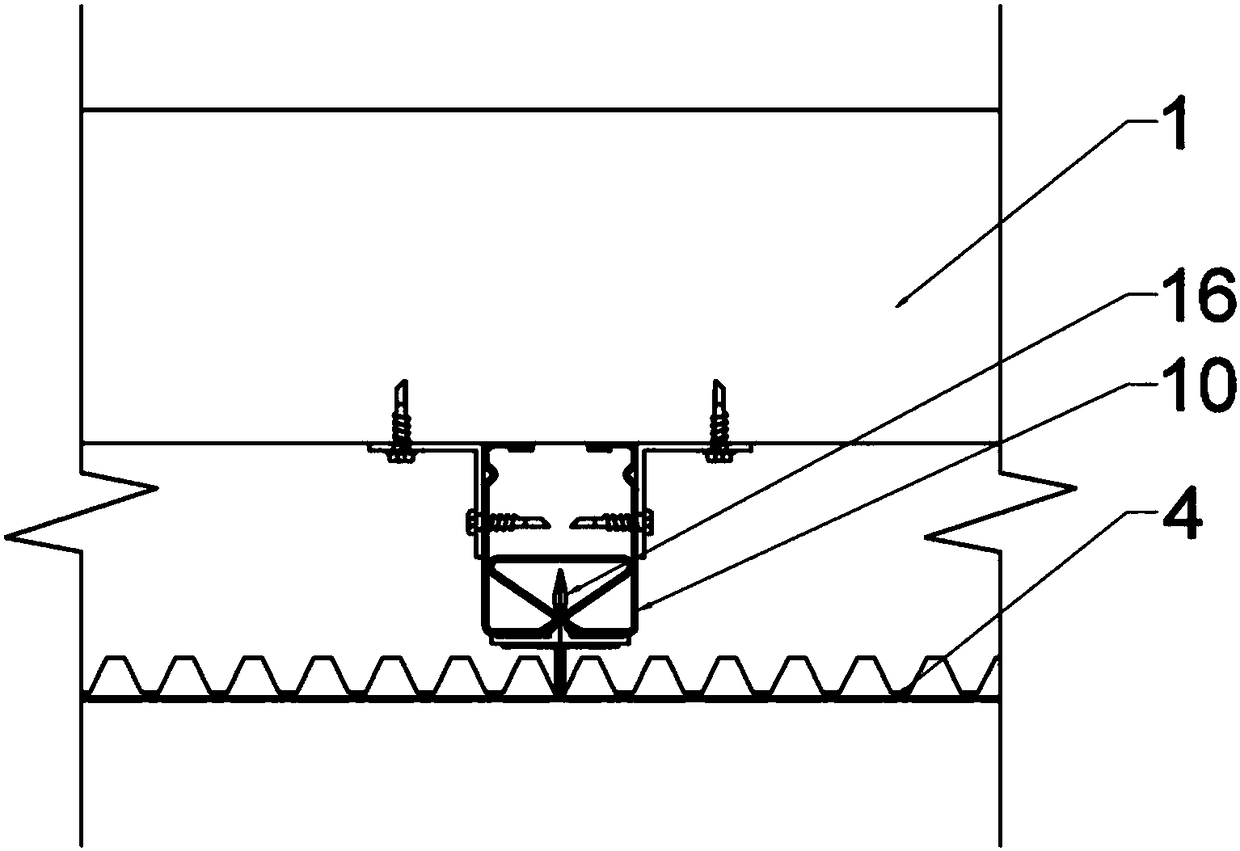

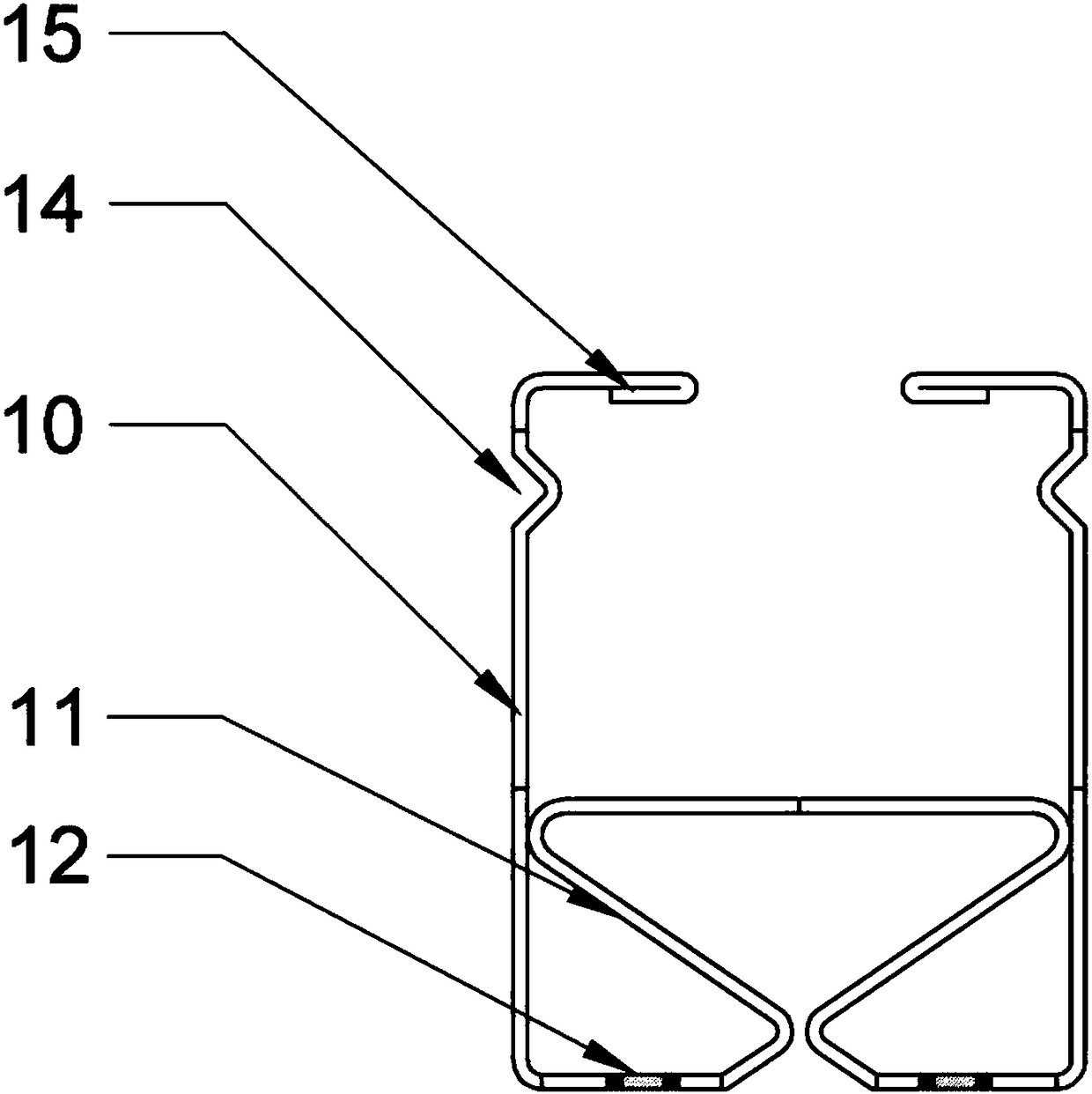

[0033] Basic as attached Figure 1-2 Shown: an all-aluminum wall panel structure, including wall panel 4, skirt waist installation part, ground 8 closing part and seamless installation part.

[0034]The wall panel 4 includes an aluminum plate layer and a corrugated plate layer fixed to the aluminum plate layer. The clapboard 4 is made of aluminum plate, so there are no environmental problems such as paint pollution and formaldehyde exceeding the standard; the setting of the steel keel can not only strengthen the fixing between the clapboard 4 and the wall 1, but also make the entire clapboard 4 form a An organic whole with an orderly layout. The setting of the corrugated board layer enhances the thickness of the wall panel 4 and the overall structural strength, and avoids the problem of the wall panel 4 collapsing due to insufficient local strength. The corrugated board layer and the aluminum board layer are fixed by bonding; it is convenient and quick to realize the fixing ...

Embodiment 2

[0045] The difference from Example 1 is only that: the corrugated board layer and the aluminum board layer of the wall panel are fixed by hot melt adhesive, and the thickness of the corrugated board layer gradually decreases from top to bottom, and between the wall board and the aluminum board layer A number of cavities are formed between them. The cavities are vertically arranged and both ends are connected. The lower ends of the cavities are equipped with sealing iron rings and sealing plugs that slide and fit with the sealing iron rings. The sealing plugs are made of magnets. Usually, the sealing plugs and the sealing iron rings The lower end of the corrugated board layer is sealed by suction, and some of the cavities are filled with aluminum sulfate solution, and some of the cavities are filled with sodium hydroxide solution; , the sealing plug and the corrugated board layer are easy to absorb heat and heat up, the sealing plug quickly reaches the Curie temperature and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com