Large buried depth thin bedrock area high seam full-mechanized caving mining pressing frame water-inrush control method

A technology of thin bedrock and thick coal seam is applied in the field of water inrush prevention and control in fully mechanized caving mining of thick coal seam in large burial depth and thin bedrock area. The effect of safe and efficient mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

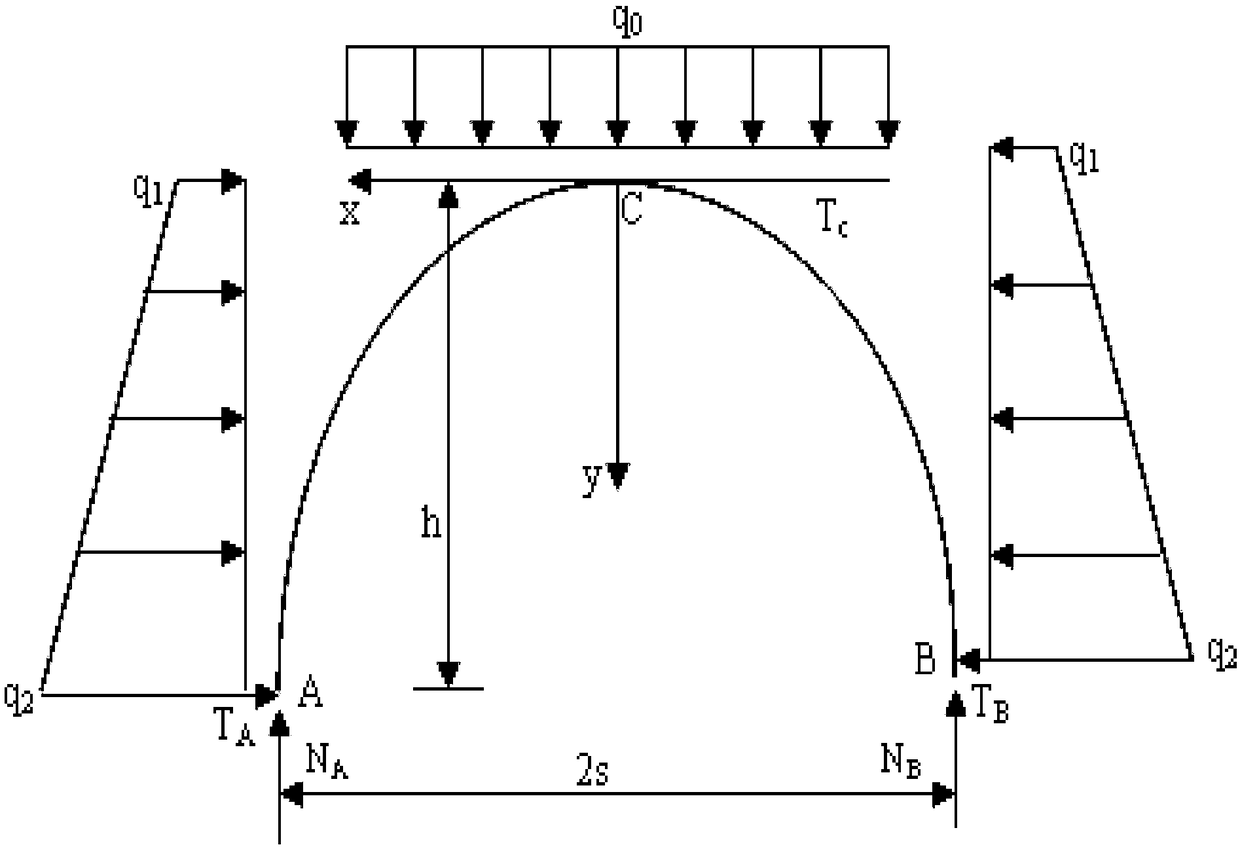

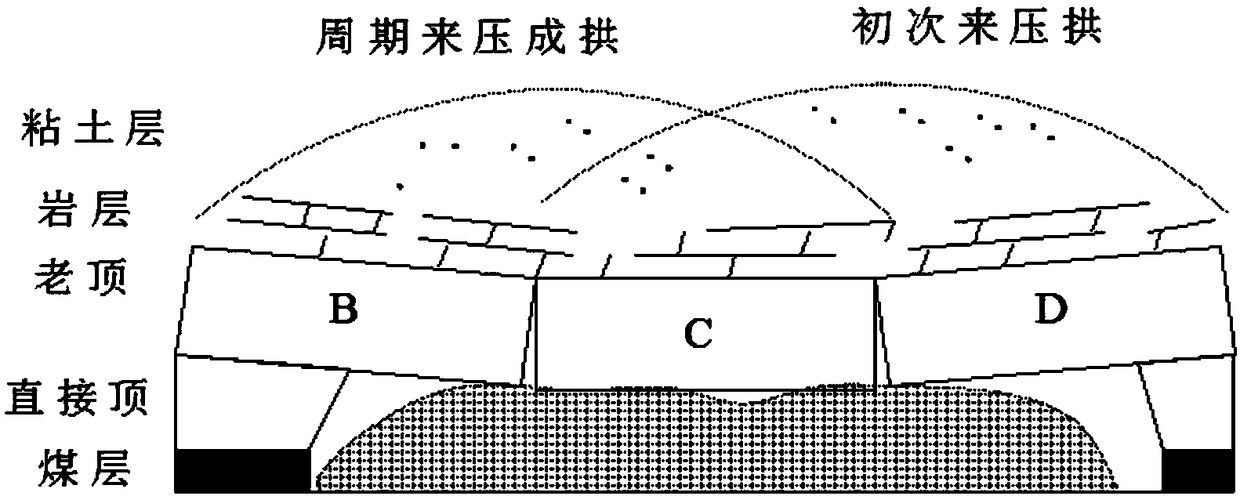

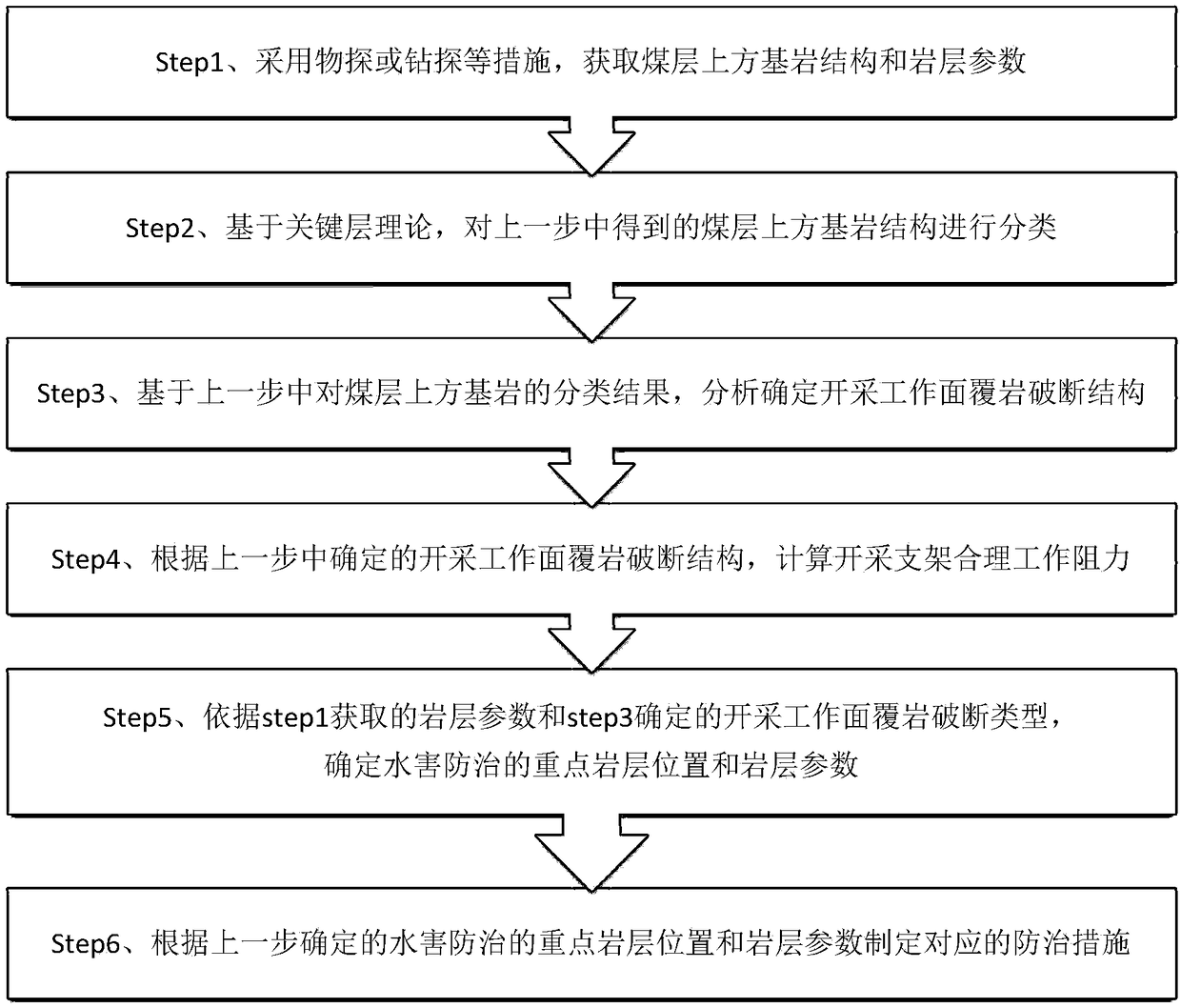

[0037] Such as figure 1 , figure 2 and image 3 As shown, a method for preventing and controlling water inrush from press frames in fully mechanized caving mining in thick coal seams with large buried depth and thin bedrock area includes the following steps:

[0038] Step 1. Obtain the bedrock structure and rock formation parameters above the coal seam by means of geophysical prospecting or drilling;

[0039] Step2, based on the key layer theory, classify the bedrock structure above the coal seam obtained in step1;

[0040] ① When there is no key layer in the overlying rock, it is called ultra-thin bedrock;

[0041] ② When there is one key layer or two composite key layers in the overlying rock, it is called thin bedrock;

[0042] ③ When there are two or more key layers in the overlying rock, it is called normal thickness bedrock.

[0043] Step3. Based on the classification results of the bedrock above the coal seam in step2, analyze and determine the fracture structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com