Reverse flow cooling tower

A countercurrent cooling and tower body technology, applied in the field of cooling towers, can solve the problems that the cooling effect of countercurrent cooling towers needs to be improved, and there is little research on the overall ventilation structure of cooling towers, so as to achieve favorable cooling effects, improve cooling efficiency, and reduce flow field resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0026] Example.

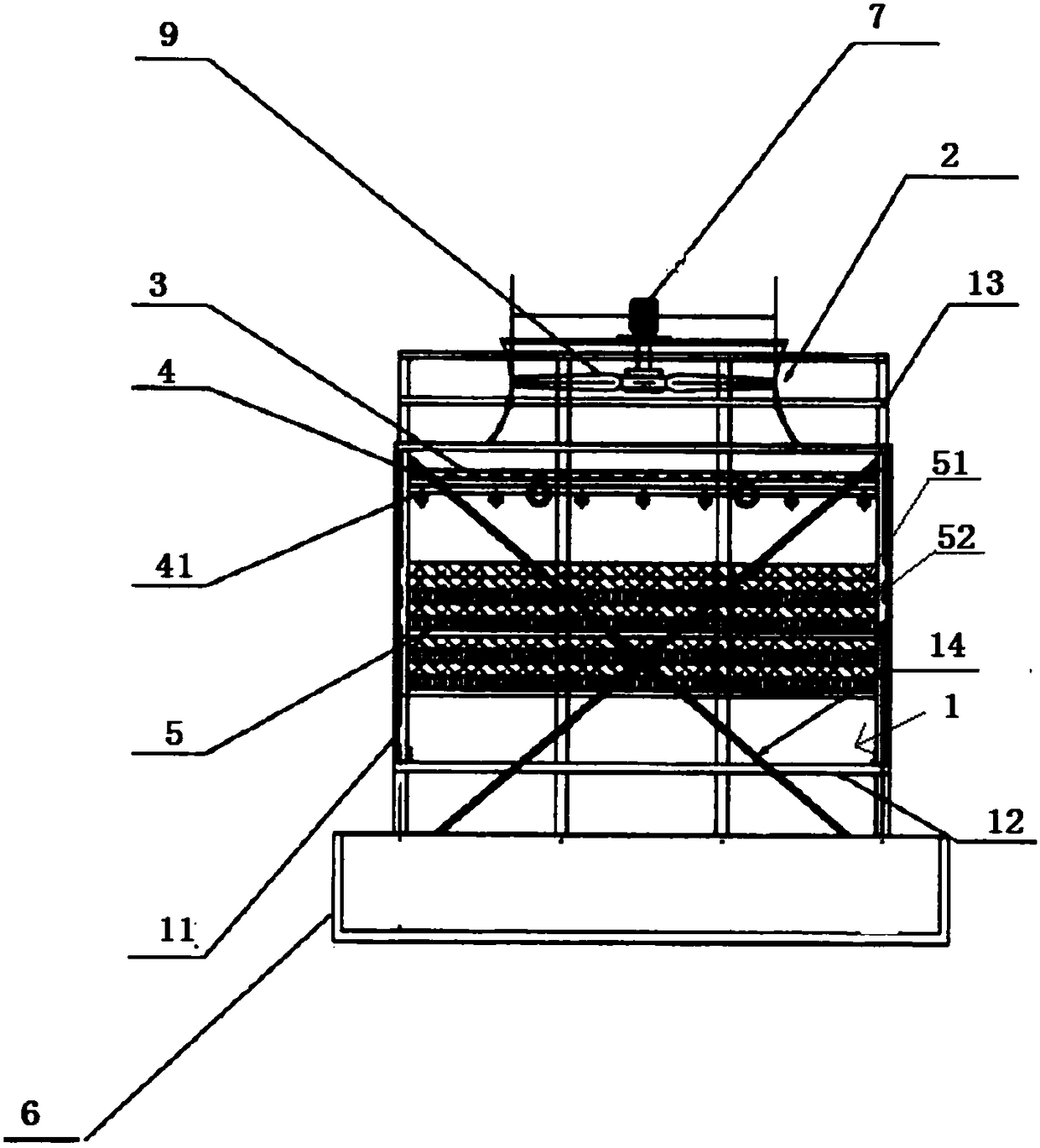

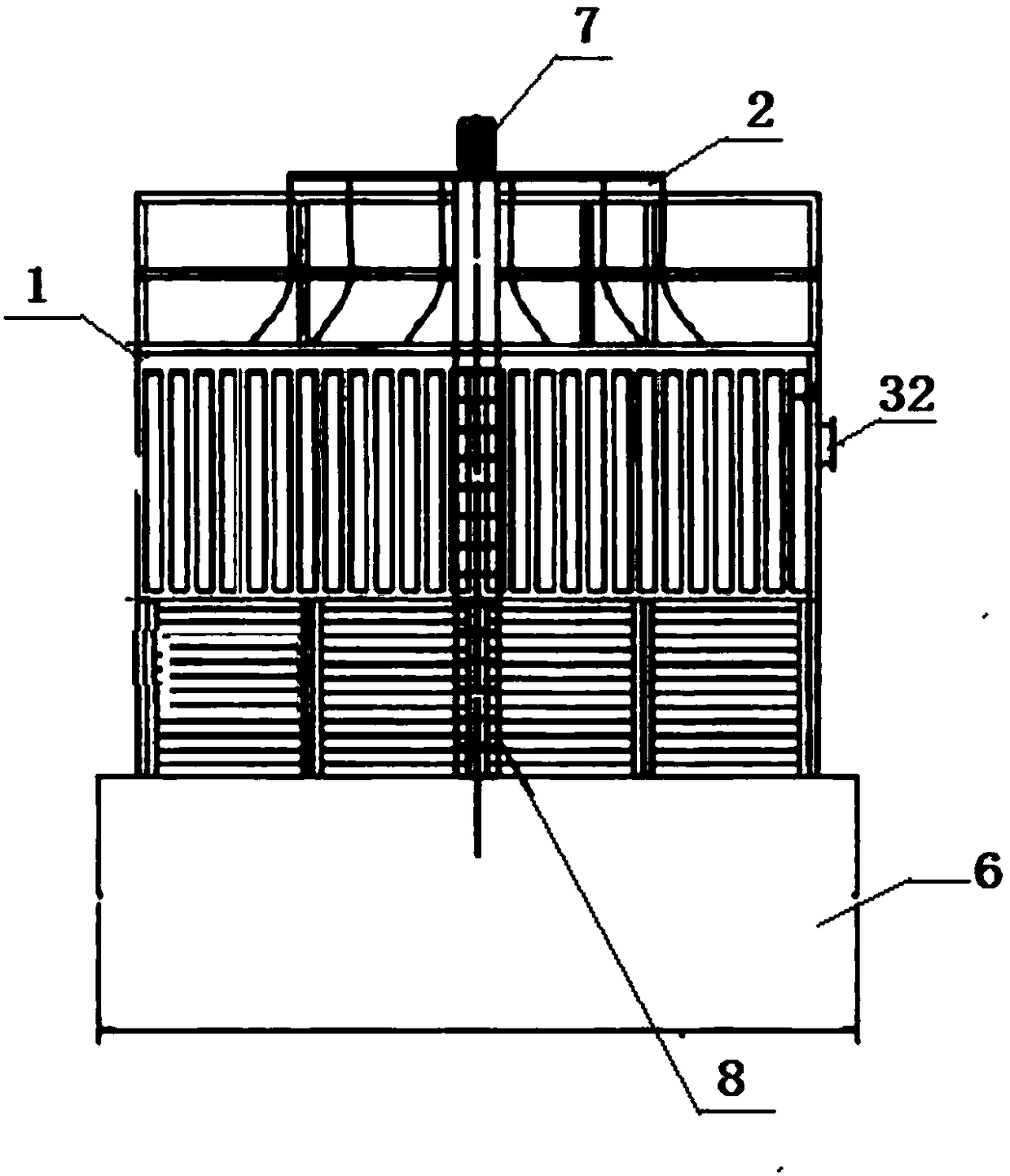

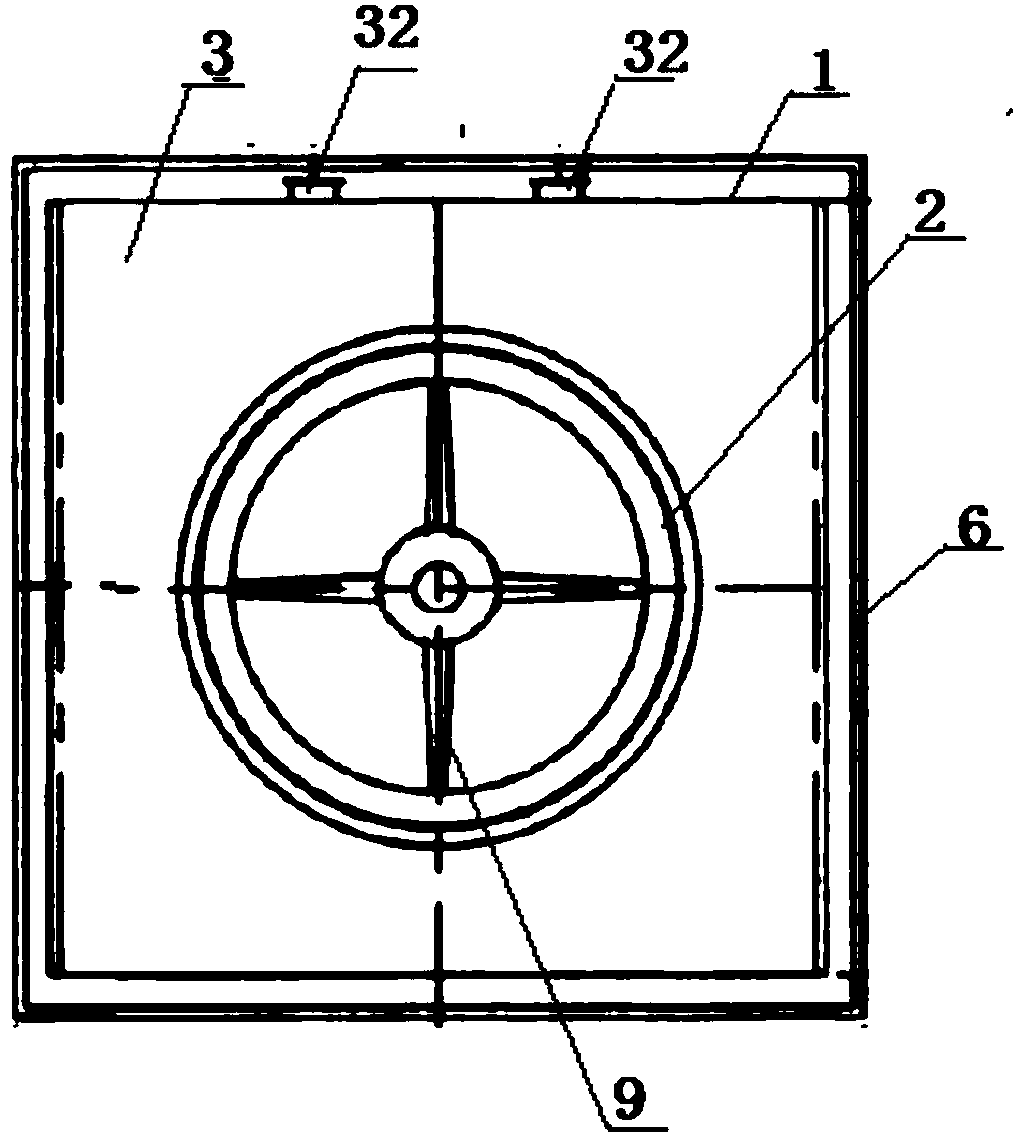

[0027] A kind of countercurrent cooling tower in the present embodiment, as figure 1 Shown, comprise tower body frame 1, be located at the air duct 2 on the top of tower body frame 1, as Figure 4 As shown, the air cylinder surface near the air outlet 22 of the air cylinder 2 is a shrinking curved surface 21, so that the flow field converges toward the middle. Such as figure 1 As shown, the fan 9 is arranged in the fan tube 2 and the air outlet 22 of the fan tube 2 is facing downward, so that the blowing of the fan is downward, and then the hot water is cooled. The bottom of the air outlet 22 of the air cylinder 2 is provided with a water eliminator 3, a spray pipe 4, a filler 5 and a pool 6 in sequence, so that the hot water enters the pool 6 after being cooled successively, and the pool 6 is a concrete pool in addition. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com