Rod length and cavity bottom thickness measuring machine of constant-speed universal joint

A constant velocity universal joint and thickness measurement technology, applied in the field of measurement tools, can solve the problems of inconvenient measurement operation and large measurement error, and achieve the effects of simple structure, reduced maintenance cost, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

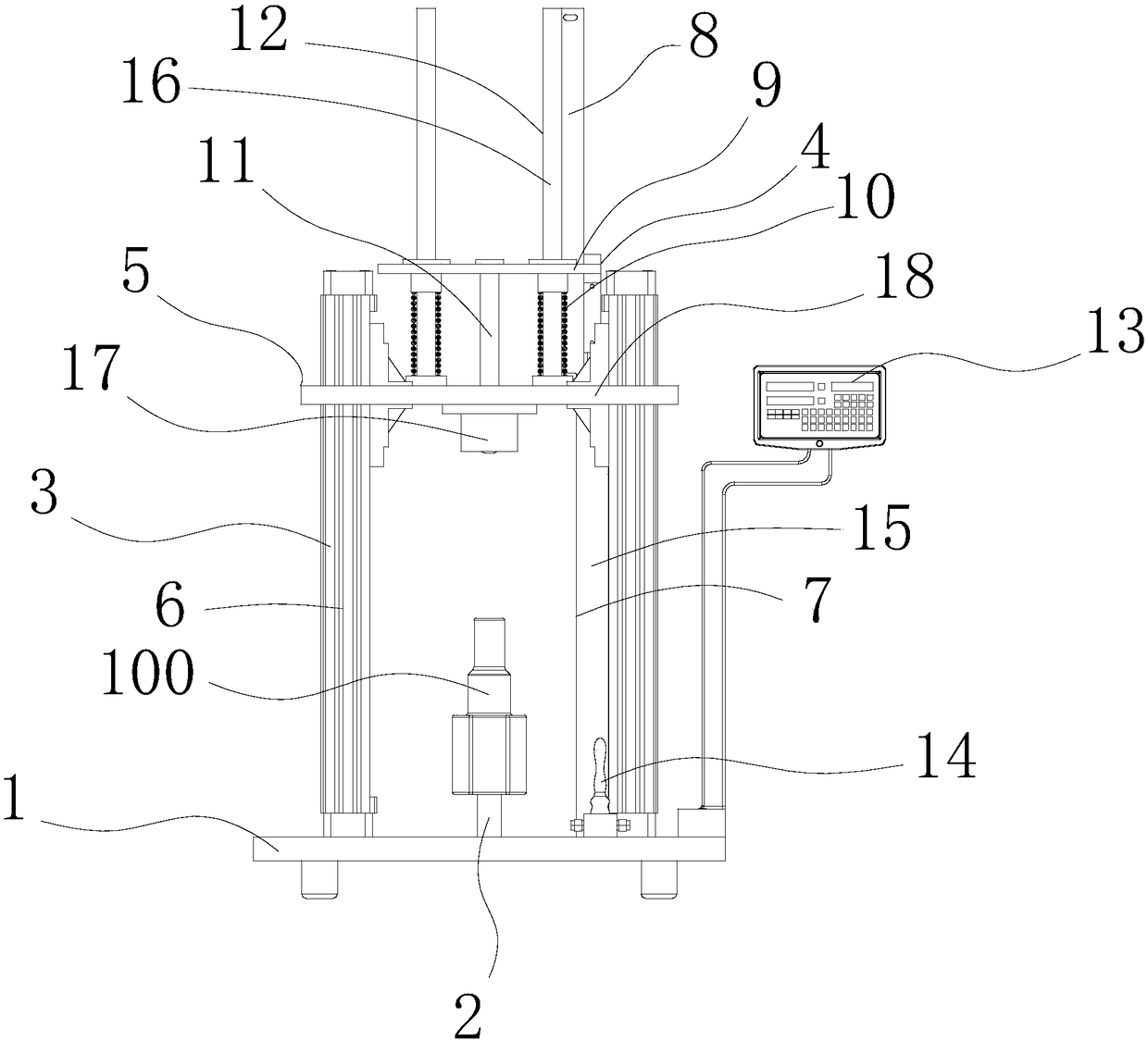

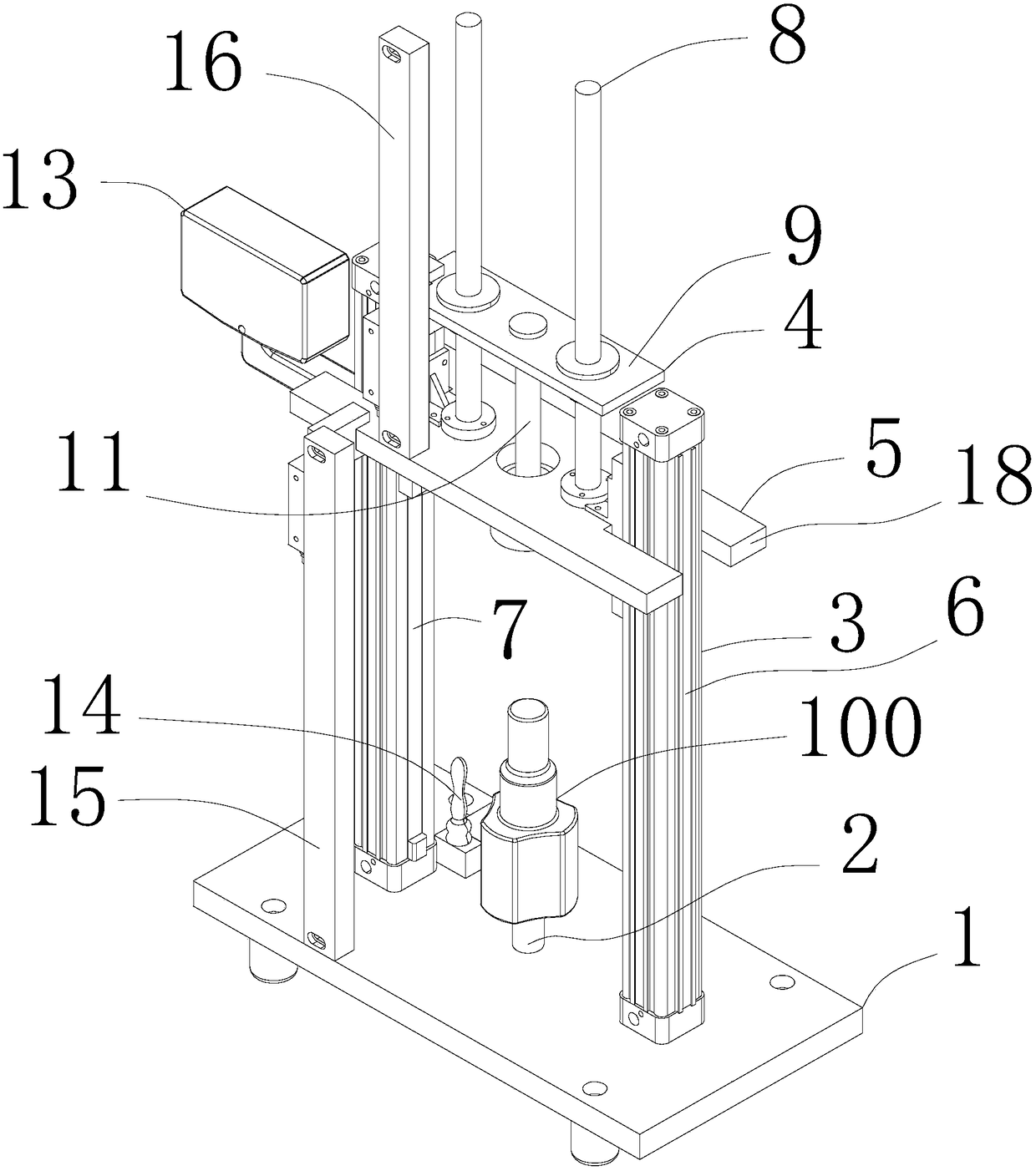

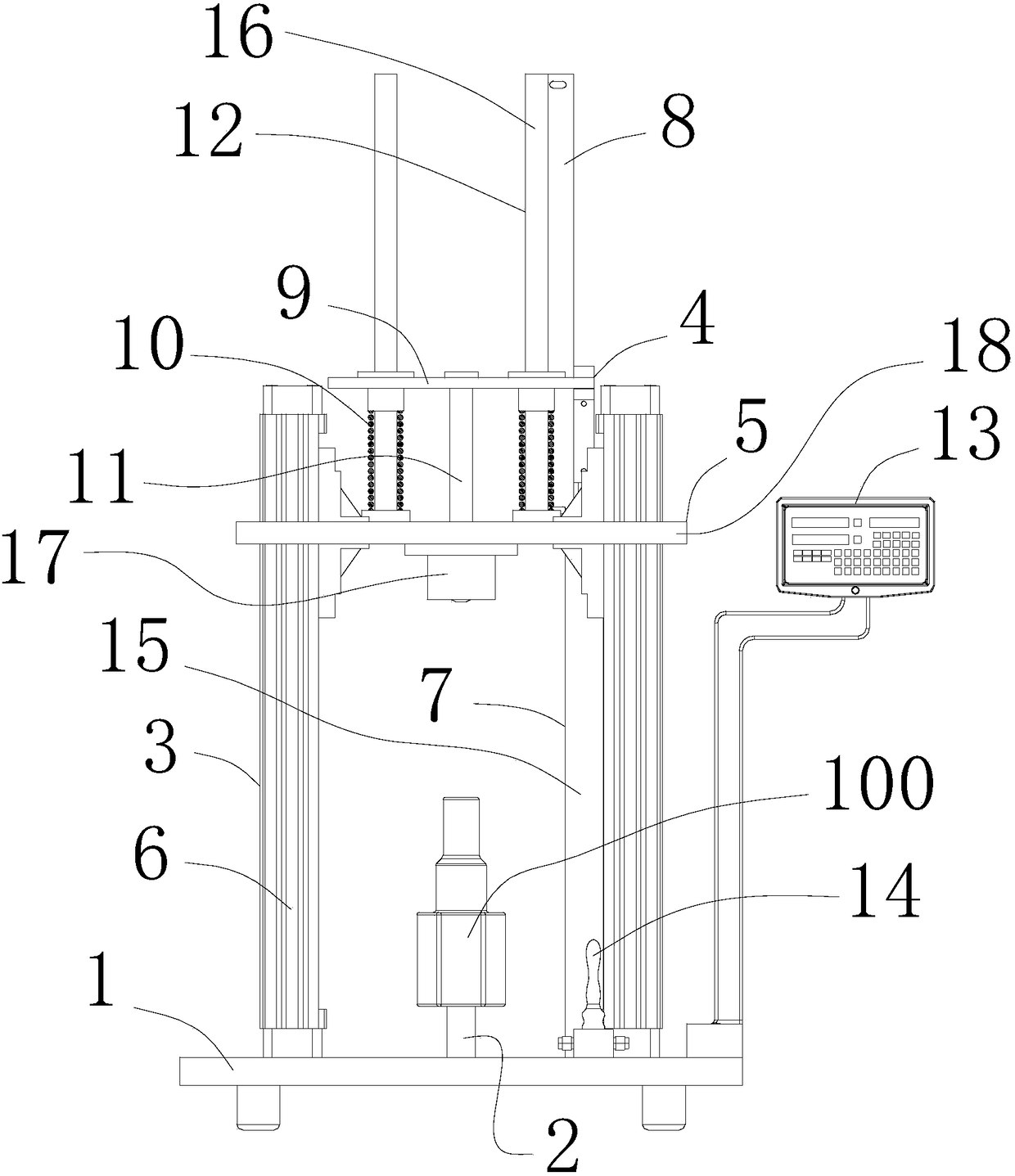

[0047] Such as figure 1 , figure 2 As shown, a constant velocity universal joint rod length and cavity bottom thickness measuring machine includes a base 1 on which a measuring mandrel 2 for positioning a workpiece 100 to be measured is fixed, and on the base 1 is also fixed There is a thickness measuring mechanism 3 for measuring the thickness of the cavity bottom of the workpiece 100 to be measured, and a length measuring mechanism 4 for measuring the rod length of the workpiece 100 to be measured is fixed on the thickness measuring mechanism 3;

[0048] Such as figure 1 , figure 2As shown, the thickness measuring mechanism 3 includes a measuring ring 5 that interferes with the workpiece 100 to be measured, and the base 1 is fixed with a driver 6 that drives the measuring ring 5 to move along the axial direction of the measuring mandrel 2. The thickness The measuring mechanism 3 also includes a thickness measuring instrument 7 for detecting the displacement distance of ...

Embodiment 2

[0063] This embodiment is a further limitation of Embodiment 1.

[0064] Such as figure 1 , figure 2 As shown, the thickness measuring instrument 7 is a first grating ruler, and the first grating ruler includes a first scale grating 15 fixed on the base 1 and a first indicator grating fixed on the measuring ring 5, The first scale grating 15 can be fixed on the base 1 through a detachable or non-detachable connection. In order to improve the fixing performance of the first scale grating 15, the first scale grating 15 can be made to lean against the driver 6, and the first scale The grating 15 is fixed to the driver 6 so that the first scale grating 15 is securely fixed.

[0065] The length measuring instrument 12 is a second grating ruler, and the second grating ruler includes a second scale grating 16 fixed on the measuring ring 5 and a second indicator grating fixed on the slider 9 .

[0066] Both the first grating ruler and the second grating ruler are common grating ru...

Embodiment 3

[0074] The display 13 includes a display screen and a processor, and the thickness measuring instrument 7 and the length measuring instrument 12 all communicate with the processor, and the processor processes the parameters measured by the thickness measuring instrument 7 and the length measuring instrument 12 Controls the display display.

[0075] The processor is a common processor in the prior art, and its main function is to process the parameters measured by the length measuring instrument 12 and the thickness measuring instrument 7, such as simple conversion and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com