Static cracking agent expansion pressure test device and method

A technology of static breaking agent and testing device, which is applied in the field of geotechnical engineering, can solve problems such as large errors and inability to measure, and achieve the effect of eliminating interference, simple test device, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

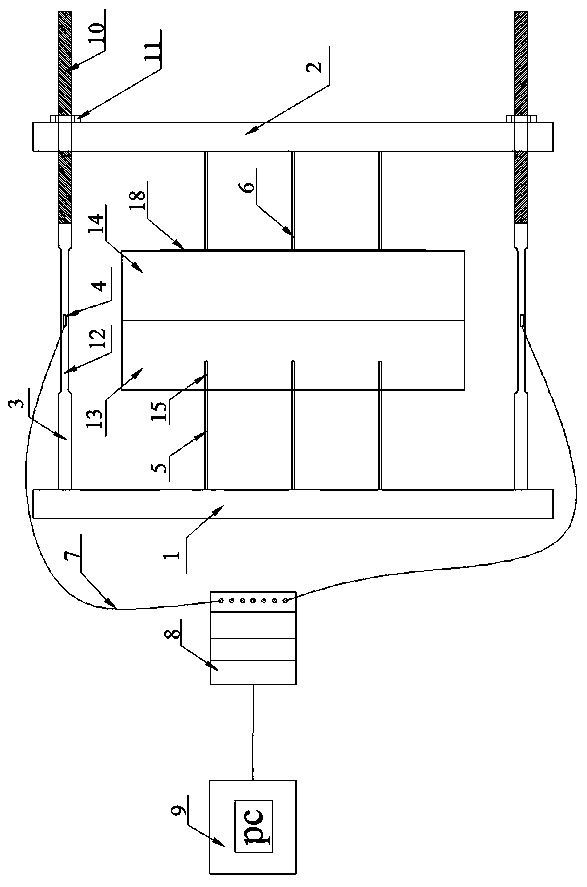

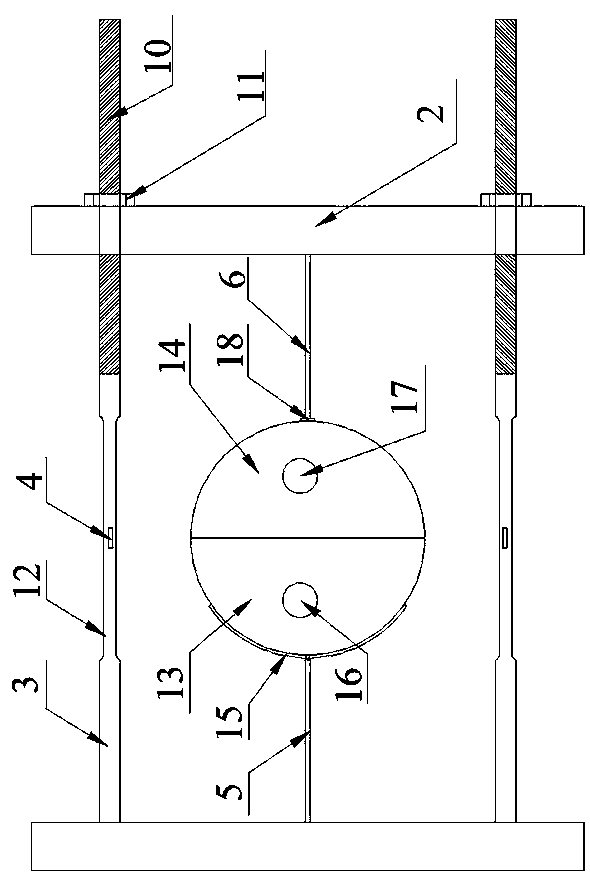

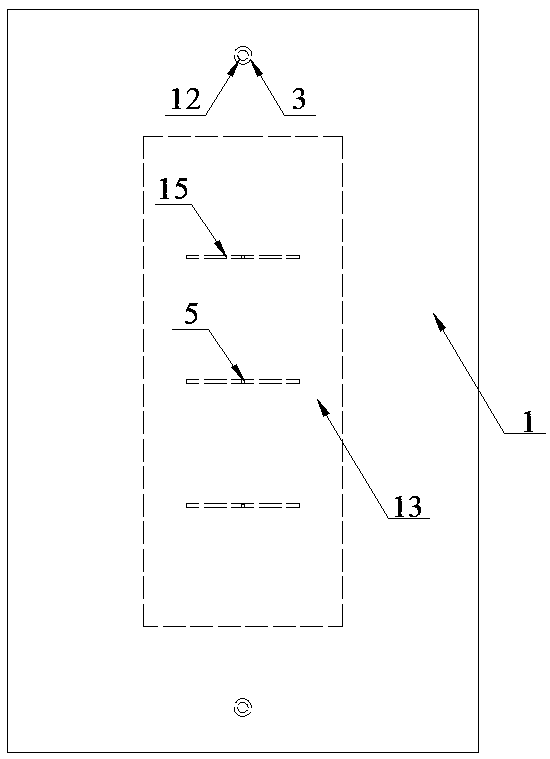

[0042] This embodiment provides a test device for static breaker expansion pressure, such as Figure 1 to Figure 4As shown, it includes the first limit plate 1, the second limit plate 2, the measuring rod 3, the resistance strain gauge 4, the test cylinder, the first limit rod 5, the second limit rod 6, and the resistance strain gauge 4 The resistance strain gauge 8 that is connected by wire 7 and the computer 9 that is electrically connected with resistance strain gauge 8; The first limiting plate 1 is fixed on the platform, and is oppositely arranged with the second limiting plate 2; Measuring bar 3 comprises smooth section and Threaded section 10; the end of smooth section is fixedly arranged on the first limiting plate 1; threaded section 10 passes through the second limiting plate 2 and is provided with a limiting nut 11 over the second limiting plate 2; A measuring section 12 is arranged on the smooth section between the position plate 1 and the second limit plate 2; the...

Embodiment 2

[0051] This embodiment provides a test method for static breaker expansion pressure, which is implemented based on the test device for static breaker expansion pressure described in Example 1, according to the expansion of static breaker hydration reaction The transmission path of the pressure is to measure the strain characteristics of the measuring section 12 through the resistance strain gauge 4, thereby calculating the size of the expansion pressure generated by the breaking agent, including the following steps:

[0052] Step 1: coupling the first half cylinder 13 and the second half cylinder 14 to form a test cylinder;

[0053] Step 2: Fix the first semi-cylinder 13 through the arc splint 15 on the first limit rod 5;

[0054] Step 3: Rotate the limit nut 11 to adjust the second limit plate 2 to move toward the second half-cylinder 14 until the second end of the second limit rod 6 abuts against the outer wall of the second half-cylinder 14;

[0055] Step 4: Polish the mea...

Embodiment 3

[0069] This embodiment takes the measurement of the expansion pressure when the mass ratio of the static breaking agent to water (water-cement ratio) is 7:3 as an example, and its specific implementation is as follows.

[0070] 1. Device construction size and processing requirements:

[0071] (1) The first semi-cylinder 13 and the second semi-cylinder 14 are semicircular thin-walled steel cylinders: radius 30mm, wall thickness 4mm, height 500mm, upper and lower bottom seals; the cut surface should be flat and smooth, and the two steel cylinders can be neatly stitched along the cut surface , there is no obvious gap and staggered seam phenomenon, and the leakage of the steel cylinder can be observed by pouring water before the test;

[0072] (2) The diameter of the grouting hole 16 on the first half cylinder 13 should be 10mm~15mm, and the diameter of the vent hole 17 on the second half cylinder 14 should be 5mm~10mm, which is convenient for grouting and hole sealing;

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com