Multistage charging aging equipment

A technology of aging equipment and aging rack, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of high cost and large power consumption, and achieve the effect of reducing aging cost, reducing energy consumption, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

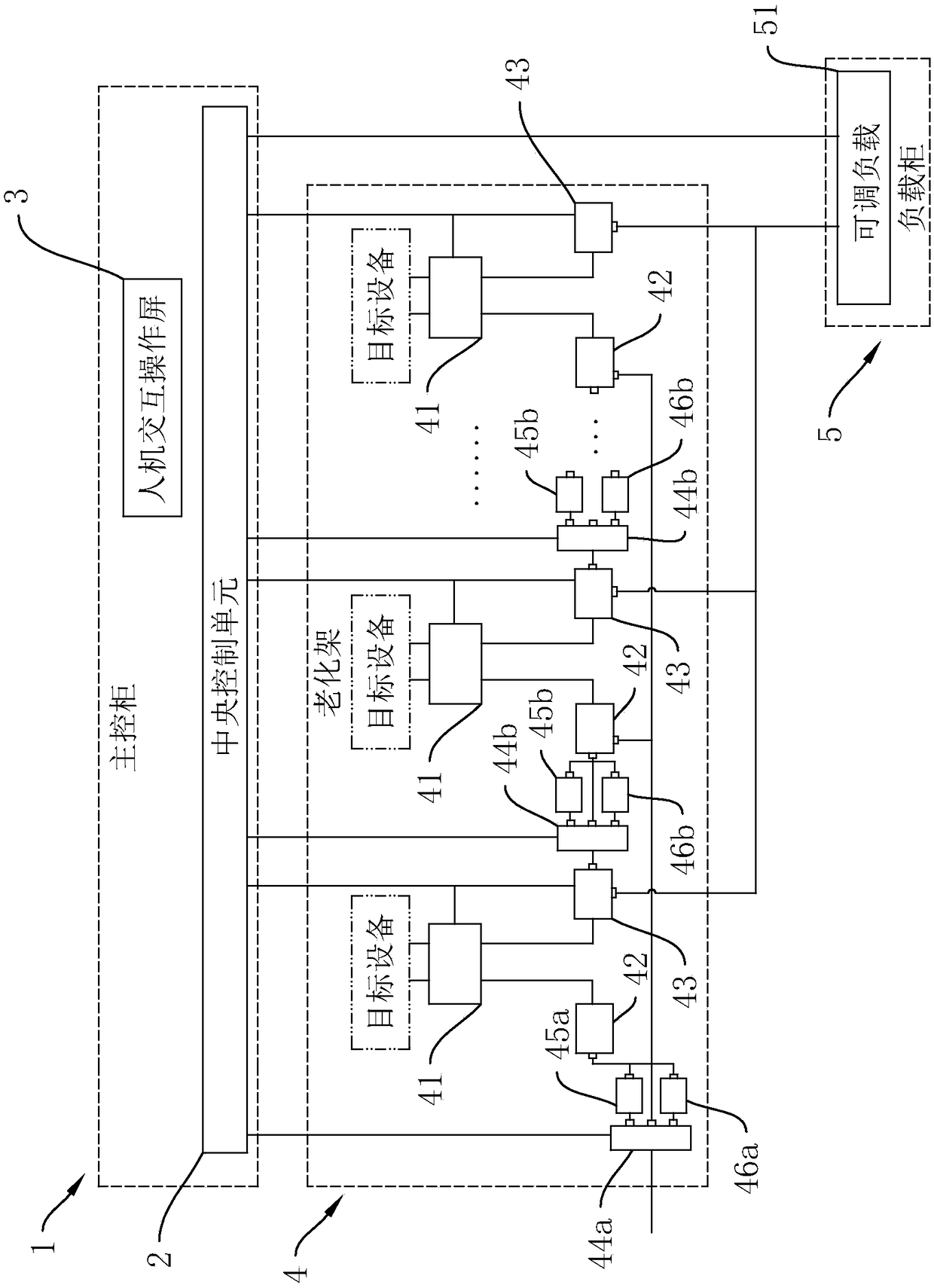

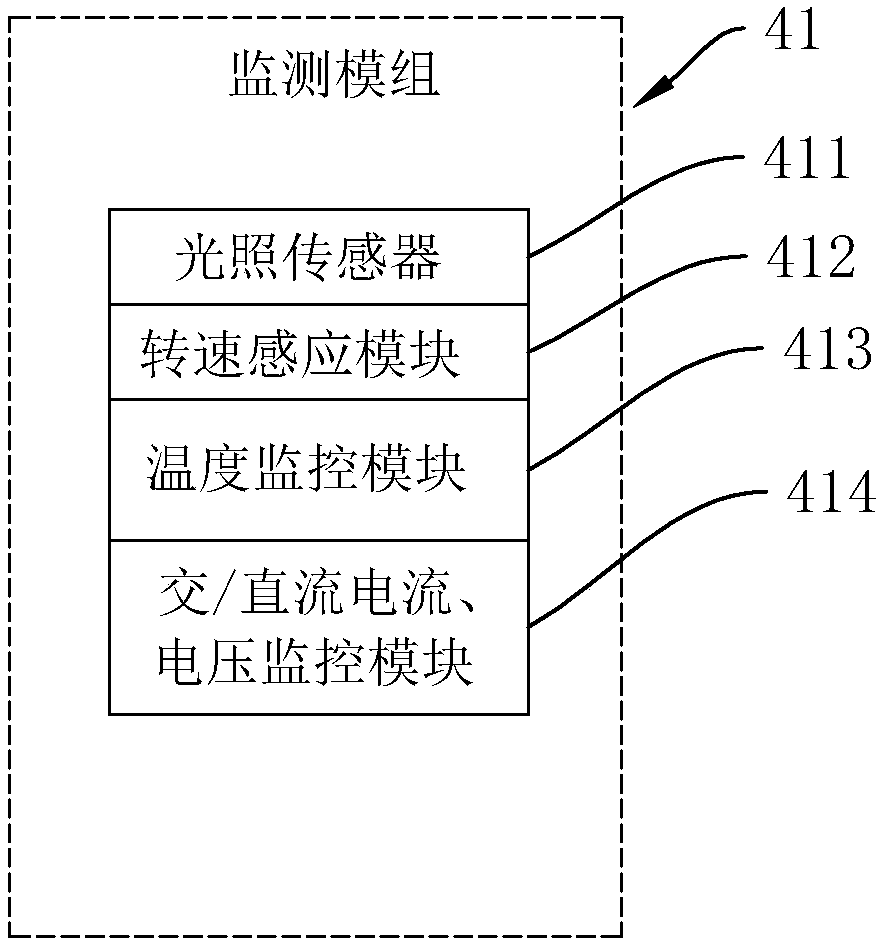

[0027] Such as figure 1 As shown, the multi-stage charging aging equipment includes a main control cabinet 1, an aging rack 4 and a load cabinet 5. The main control cabinet 1 is provided with a central control unit 2; the aging rack 4 is provided with a multi-stage monitoring module 41 for monitoring The operating parameters of the target equipment in the aging process, the monitoring modules 41 at all levels can be connected in series, in parallel or in combination with the target equipment according to the specific conditions of the target equipment, and all the monitoring modules 41 are connected with the central The control unit 2 is electrically coupled, in this embodiment, as figure 2 As shown, the monitoring module 41 is provided with an illumination sensor 411, which can be used for the illumination parameters of lighting equipment such as lamps and lanterns. 41 is provided with an AC / DC current and voltage monitoring module 413 and a temperature monitoring module 41...

Embodiment 2

[0033] When the operating current of the target device does not match the nature of the mains input current, on the basis of the above embodiments, a multi-directional control switch 44a is provided on the mains input circuit of the monitoring module 41, and the multi-directional control switch and the central control The unit 2 is electrically connected; when the monitoring modules 41 at all levels are connected in series, the first contact of the multidirectional control switch 44a is directly electrically connected to the power input connector 42, and the second contact of the multidirectional control switch 44a is connected to the power input connector 42. The circuit between the input connectors 42 is provided with a rectifier 45a, which can convert the input current of the first-level target equipment into direct current. Similarly, when the monitoring modules 41 of all levels are connected in parallel, the rectifier 45a is arranged on the On the total input circuit, the ...

Embodiment 3

[0039] When the monitoring modules 41 at all levels are connected in series, and the target equipment is AC input and DC output, a multi-directional control switch 44b is provided on the circuit between the power output terminal and the power input connector 42 of the next stage, The multidirectional control switch 44b is electrically connected with the central control unit 2; the first contact of the multidirectional control switch 44b is directly electrically connected with the power input connector 42, and the second contact of the multidirectional control switch 44b is connected with the power input connector 42. If an inverter 46b is provided on the circuit between them, the aging of the target equipment connected to the monitoring modules 41 at all levels can be realized. For target equipment such as charging piles and rectifiers, the direct current output by the upper-level target equipment can also be passed through The conversion of the inverter 46b is used for the agi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com