Track Vegetable Harvesting Machinery

An orbital, vegetable technology, applied to harvesters, agricultural machinery and tools, and cleaning methods using liquids, etc., can solve the problems of inaccurate cutting position adjustment of cutting knives, affecting vegetable re-growth, and vegetable dispersal and confusion, etc., to achieve It is beneficial for post-cleaning, avoiding high-level shearing, and avoiding the effect of contacting the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

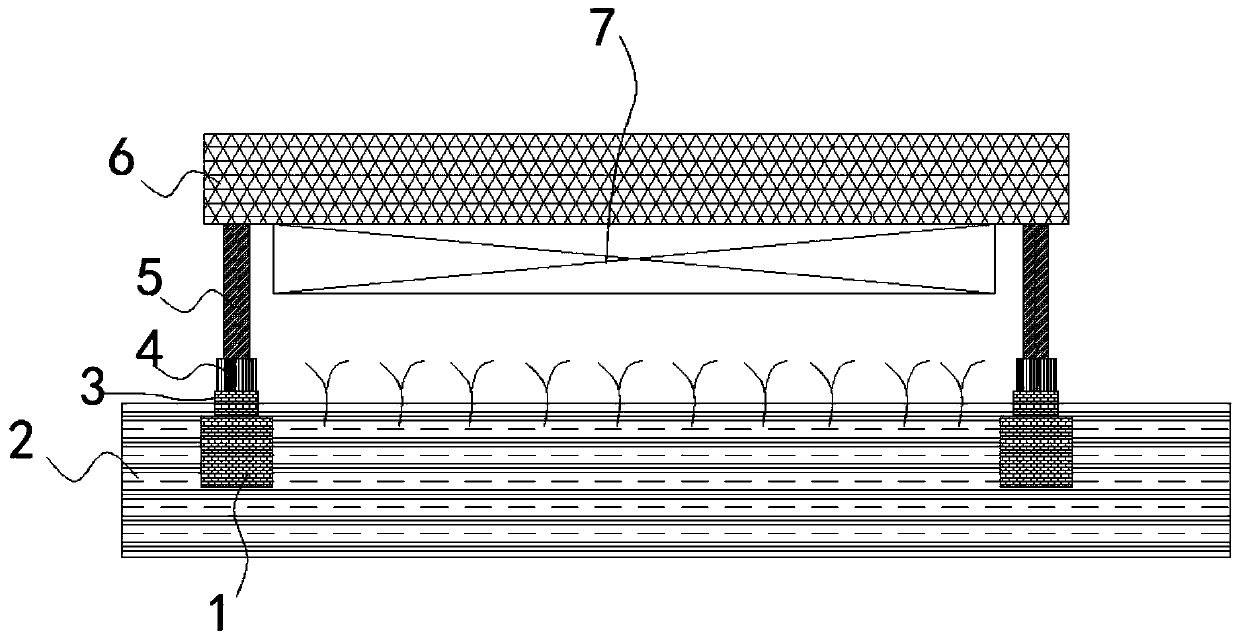

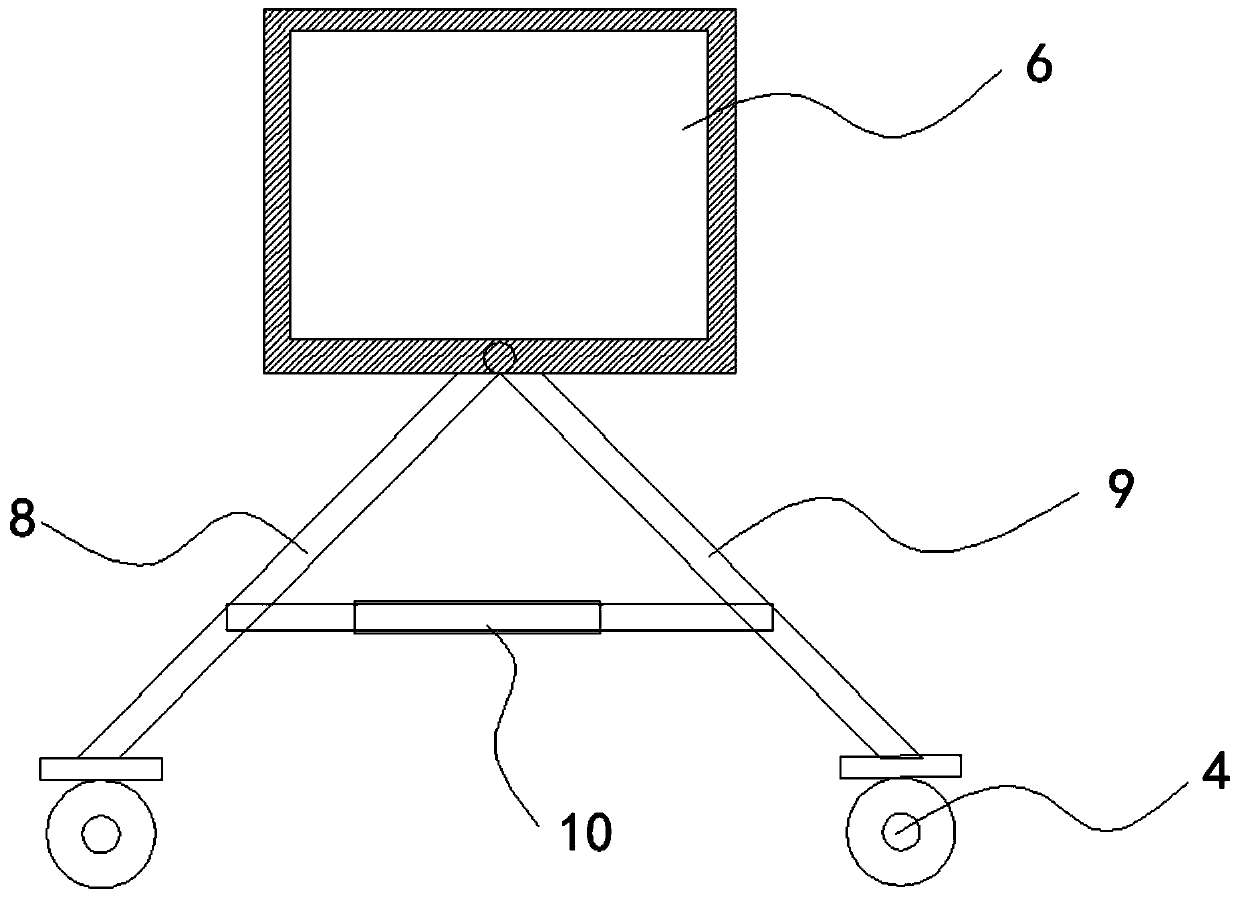

[0032] Such as figure 1 , 2 , 3, 4 and 5, a track-type vegetable harvesting machine, including:

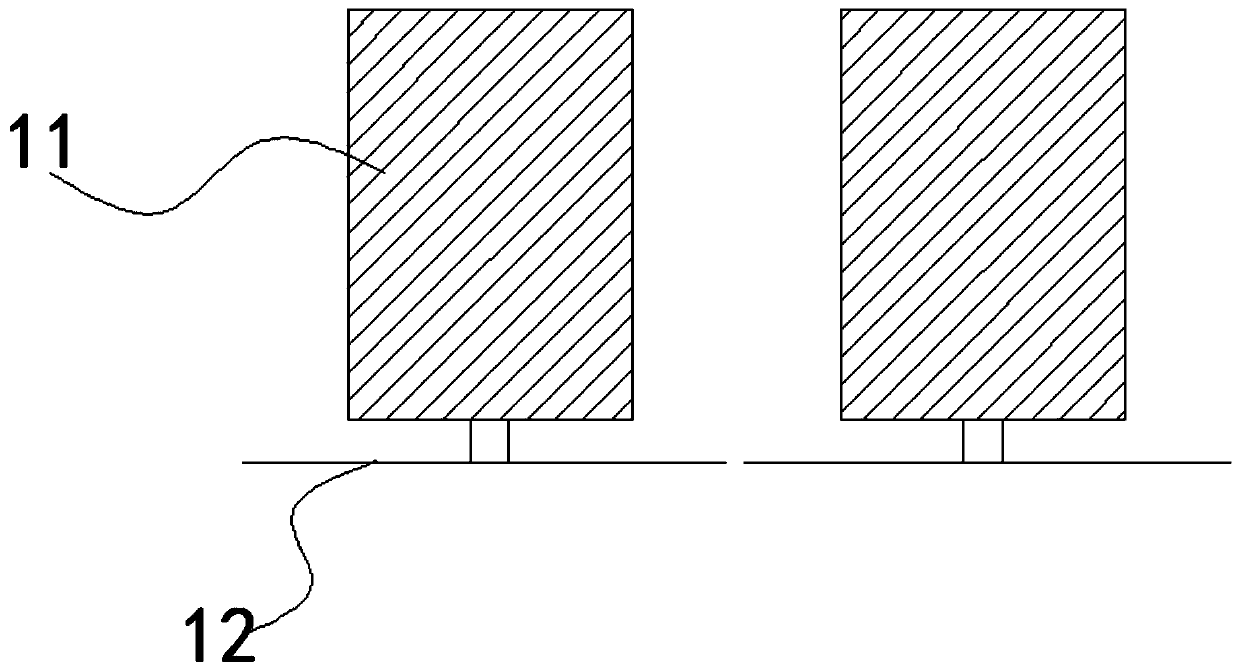

[0033]A plurality of running tracks arranged in the planting field 2, such as a flat square field or a greenhouse, the running tracks can be arranged on the field ridge, or on both sides of the greenhouse, and the running tracks are parallel to each other, and the running tracks include The installation foundation 1 is such as a cement foundation, a guide rail fixed on the installation foundation such as a rail, a closing mechanism for selectively closing the guide rail, and a cleaning mechanism for cleaning the guide rail. The lower part of the installation foundation is buried in the ground, and the upper part protrudes from the ground. The convex portion 3 is formed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com