Smoke dust filter device for petroleum refining process

A fume filter device and process technology, which is applied in combination device, dispersed particle filtration, use of liquid separation agent, etc., can solve the problems of environmental air pollution, unsatisfactory smoke and dust filtration effect, etc., and achieve the effect of good filtration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

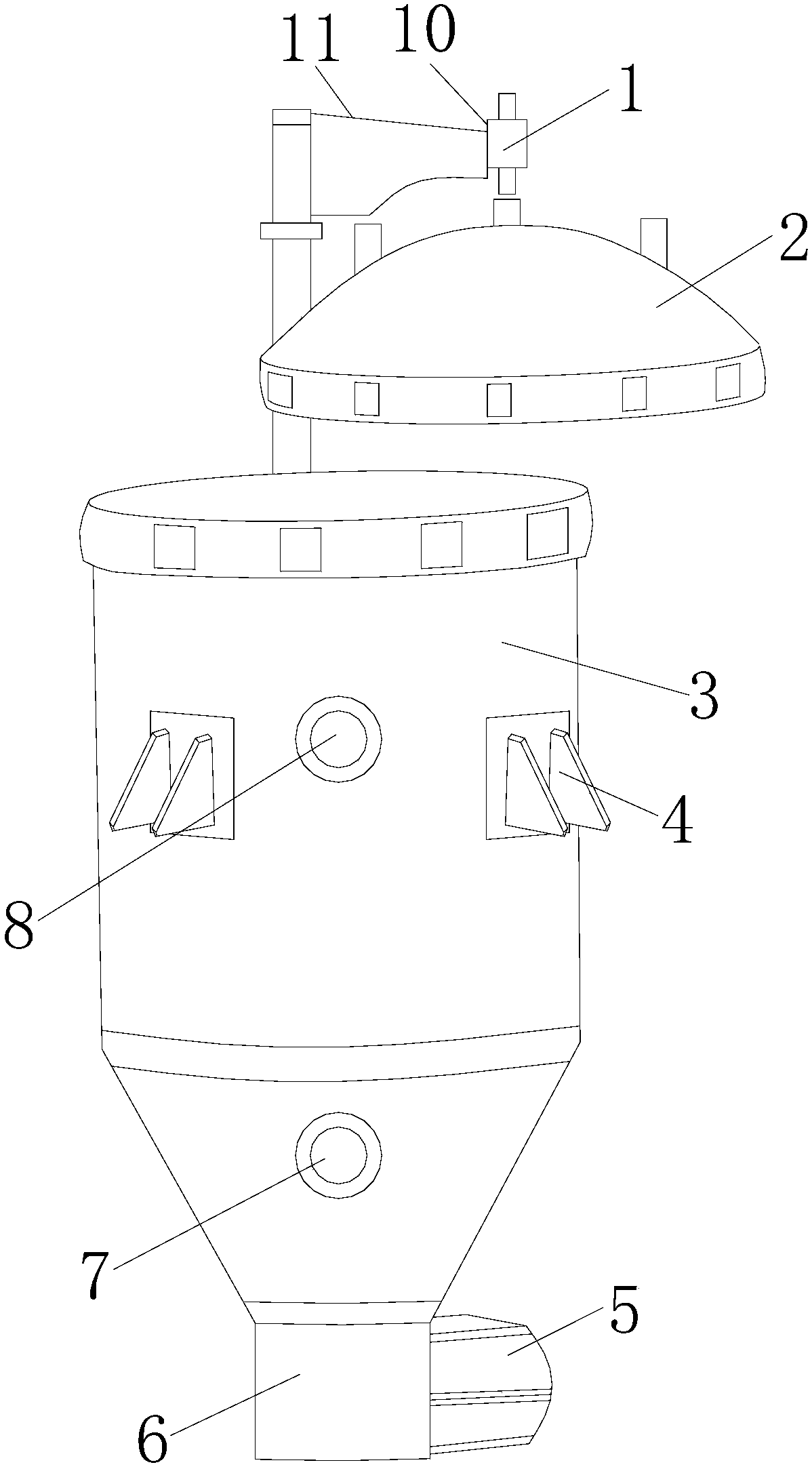

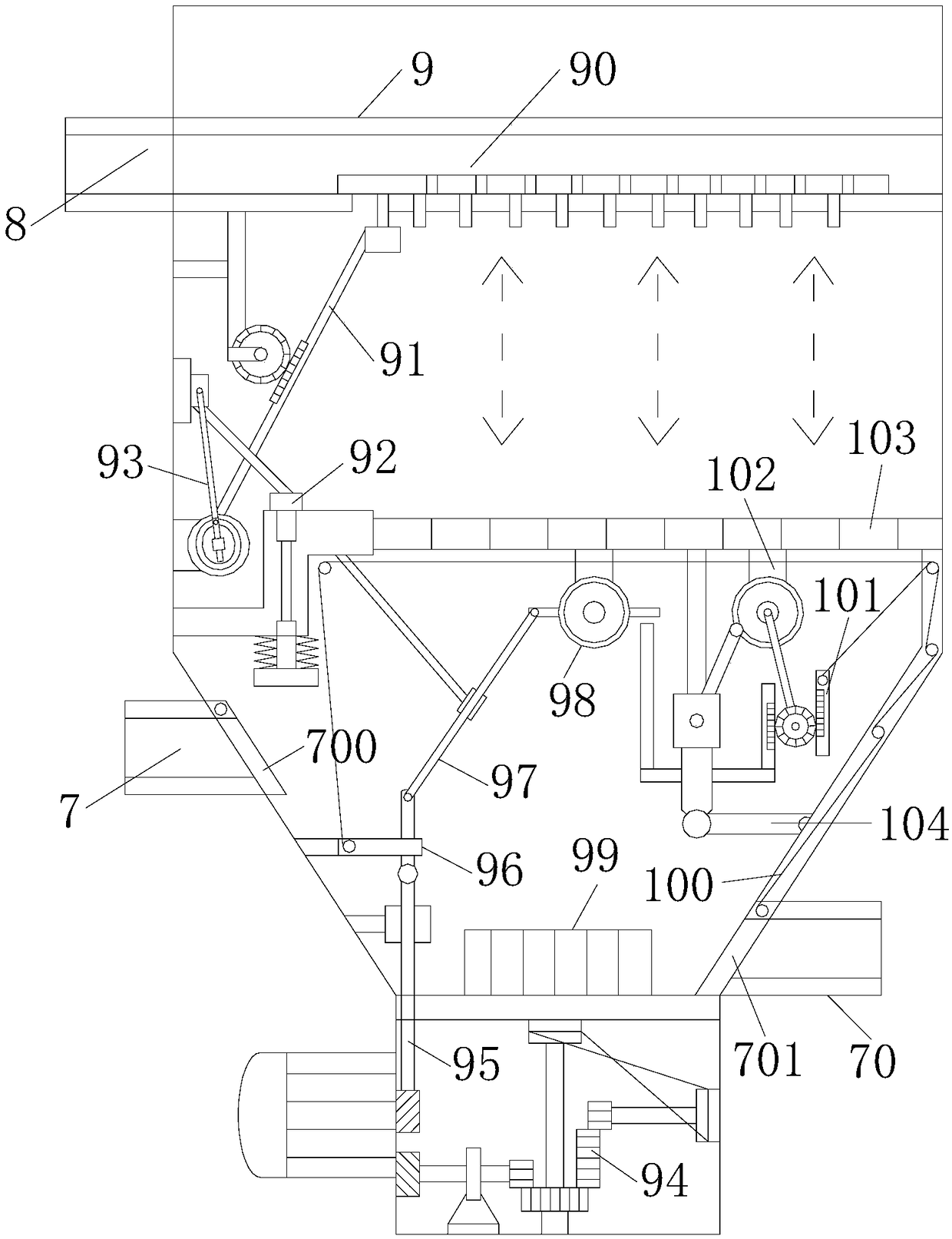

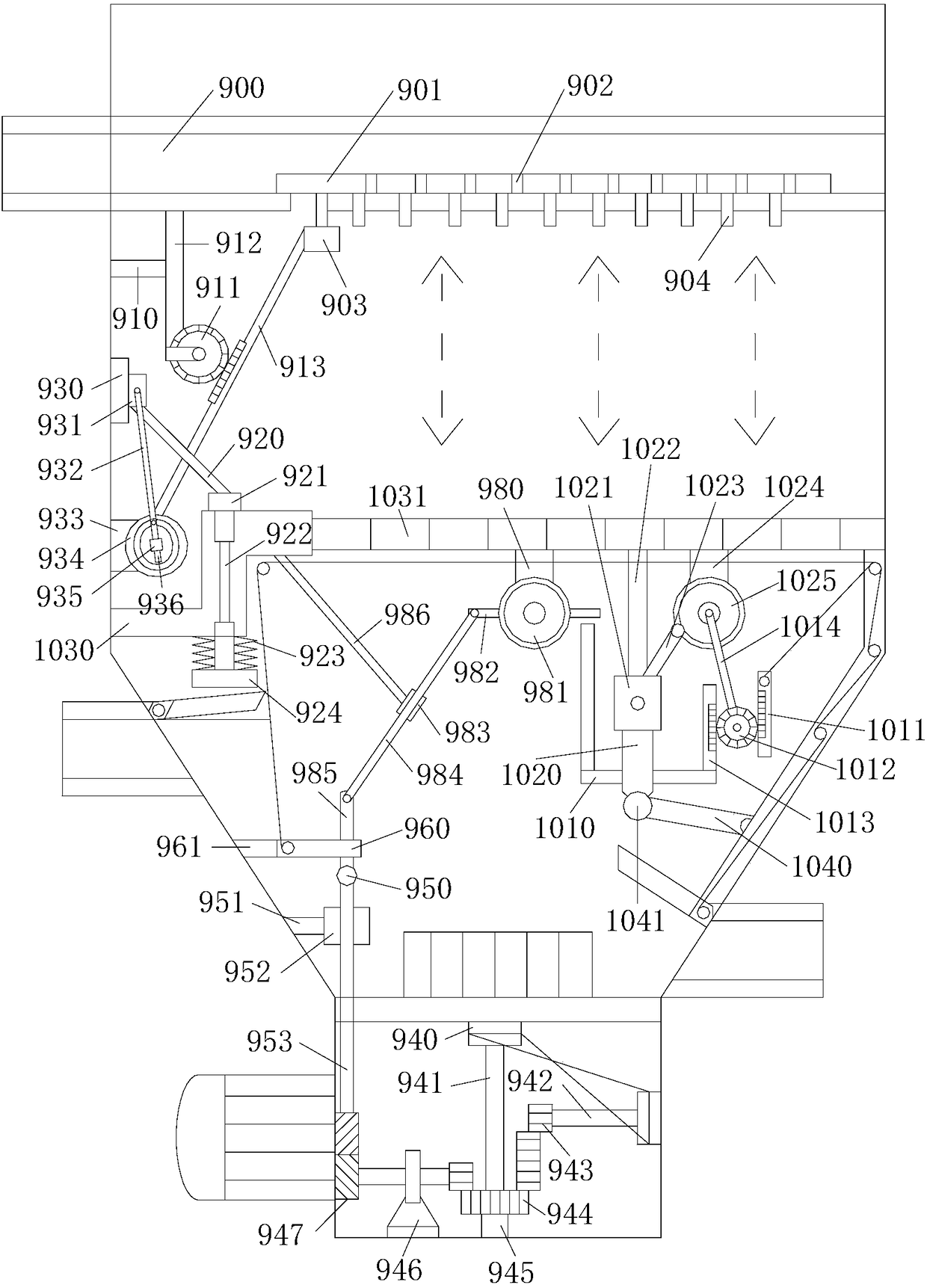

[0027] see Figure 1-Figure 3 , the present invention provides a kind of soot filtering device for petroleum refining process: its structure includes filter plug structure 1, cylinder cover 2, cylinder body 3, lifting frame plate 4, motor 5, machine base 6, air inlet nozzle 7, inlet Water pipe mouth 8, air filtering device 9, the filter plug structure 1 is locked on the side of the cylinder body 3, the filter plug structure 1 cooperates with the cylinder cover 2, the cylinder cover 2 is disassembled and connected with the cylinder body 3, and the lift The frame plate 4 is provided with a pair, welded on the outer surface of the cylinder body 3, the cylinder body 3 is provided with an air inlet nozzle 7, a water inlet nozzle 8, and the water inlet nozzle 8 is located in the middle of the frame plate 4, and the The liquid pipe mouth 7 has the same structure as the water inlet pipe mouth 8, the cylinder body 3 is provided with a liquid outlet 70, and the liquid outlet 70 is symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com