Manufacturing method for hexagonal seamless tube

A manufacturing method and technology for seamless pipes, which are used in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of overall consideration of surface quality uniformity and pipe performance uniformity, and achieve good surface quality, uniform and stable performance. , the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

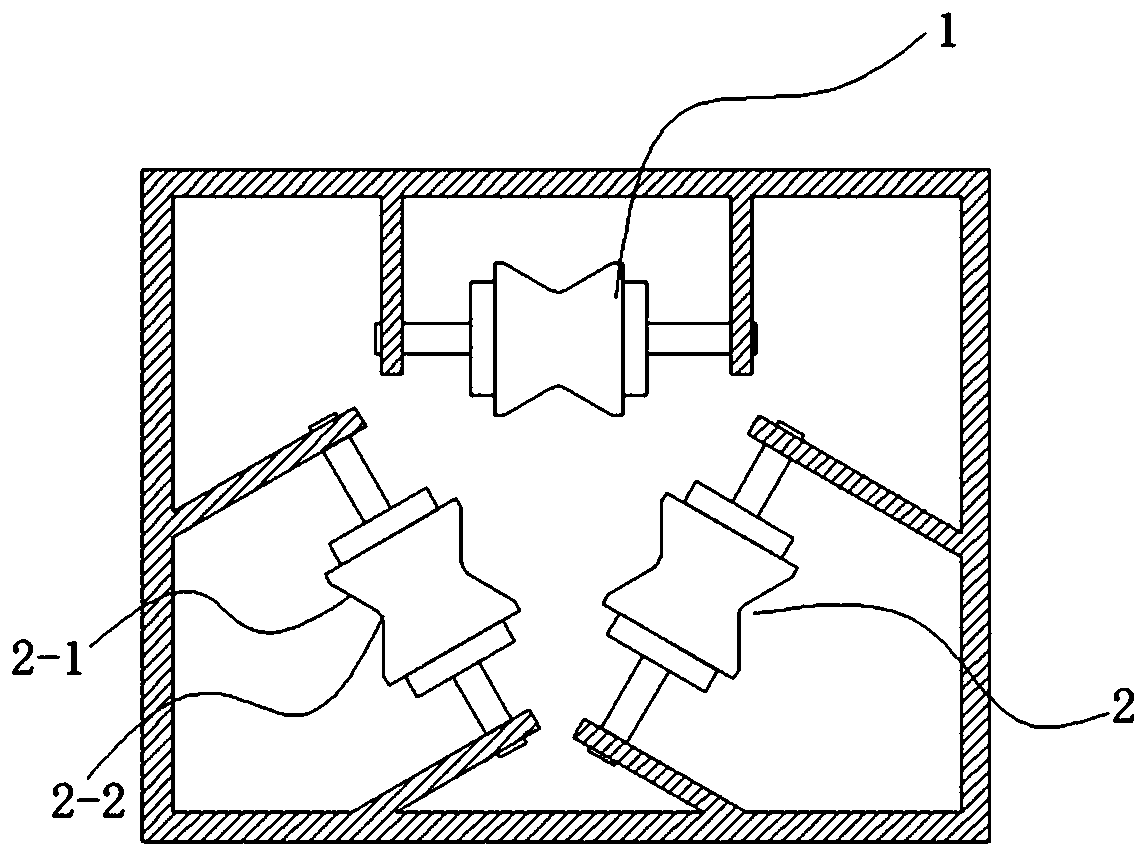

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Embodiments of the present invention include the following specific steps:

[0023] Step 1, cold rolling processing, the C276 alloy billet is cold rolled at least twice to complete the production of the intermediate round tube. In this step, the billet needs to be cold rolled multiple times, and the feed rate in the cold rolling process is 1~3.4mm , The rolling speed is 10~100n / min. Multi-roll mill rolling is conducive to the control of the quality of the inner and outer surfaces of the pipe, especially the quality control of the inner surface, and is conducive to the control of the dimensional accuracy of the pipe. Through experiments, it is found that when the deformation increases from 15% to 50%, the yield strength of the billet gradually increases from 900MPa to 1250MPa, and the increase is relatively uniform. If a multi-roll mill is used, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com