Full-automatic waste-free high quality blanking and edge rolling mold

A waste-free, high-quality technology, applied in the field of punching and rolling dies, can solve the problems of long processing time, large springback, and low efficiency, and achieve the effect of eliminating shrinkage springback stress, small springback, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

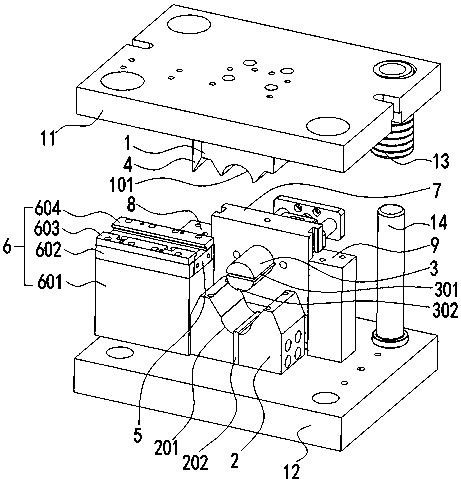

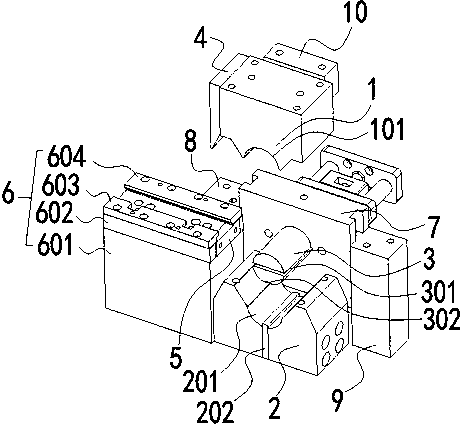

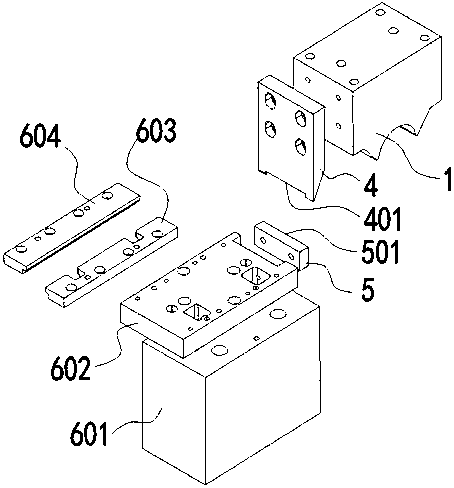

[0028] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine Figure 1-Figure 8 The accompanying drawings describe the present invention in further detail.

[0029] refer to figure 1 The full-automatic no-waste high-quality punching and rolling die shown includes forming upper die 1, forming lower die 2, forming mandrel 3, upper blade block 4, lower blade block 5, feeding group 6, mandrel Mounting plate 7, first guide slider 8, second guide slider 9, upper template 11, lower template 12, guide sleeve 13, guide post 14, molding upper mold 1 is arranged above molding lower mold 2, molding mandrel 3 It is arranged between the forming upper mold 1 and the forming lower mold 2. The forming upper mold 1 is installed on the upper template 11, the forming lower mold 2 is installed on the lower template 12, and the forming mandrel 3 is installed on the mandrel mounting plate 7. A guide slider 8 and a second guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com