Hinge resistance welding process

A resistance welding and resistance welding machine technology, applied in resistance welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of strong environmental damage, environmental pollution, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

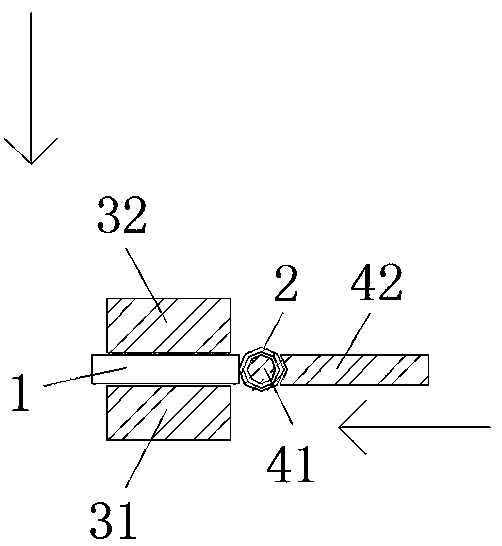

[0023] Embodiment one, refer to figure 1 As shown, the hinge resistance welding process of the present invention, the hinge includes a leaf 1, and a shaft sleeve 2 assembled with the leaf 1, the shaft sleeve 2 is cut from a steel pipe, and the shaft sleeve 2 is provided with an inner hole. The leaf 1 is cut by steel strip or steel plate. The manufacture of the hinge is to weld the leaf 1 and the bushing 2 by resistance welding process. Firstly, the leaf 1 and the bushing 2 are precisely positioned and then passed The resistance welding process is welded by the resistance welding process, and the resistance welding process is controlled by the resistance welding welding system. The resistance welding welding system includes a shaft sleeve positioning tooling system and a sheet positioning tooling system. The sheet positioning tooling system includes a reference electrode 31 and a sheet limiter. The fixed electrode 32, the shaft sleeve positioning tooling system includes the sha...

Embodiment 2

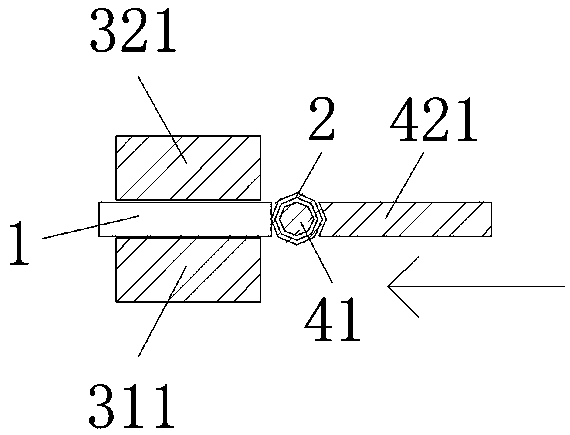

[0025] Embodiment two, refer to figure 2As shown, the hinge resistance welding process of the present invention, the hinge includes a leaf 1, and a shaft sleeve 2 assembled with the leaf 1, the shaft sleeve 2 is cut from a steel pipe, and the shaft sleeve 2 is provided with an inner hole. The leaf 1 is cut by steel strip or steel plate. The manufacture of the hinge is to weld the leaf 1 and the bushing 2 by resistance welding process. Firstly, the leaf 1 and the bushing 2 are precisely positioned and then passed Welded by resistance welding process, the resistance welding process is controlled by the resistance welding welding system, the resistance welding welding system includes a shaft sleeve positioning tooling system and a leaf positioning tooling system, and the leaf positioning tooling system includes a reference electrode and a leaf limit fixation The electrode, the shaft sleeve positioning tooling system includes the shaft sleeve positioning shaft 41 and the shaft sl...

Embodiment 3

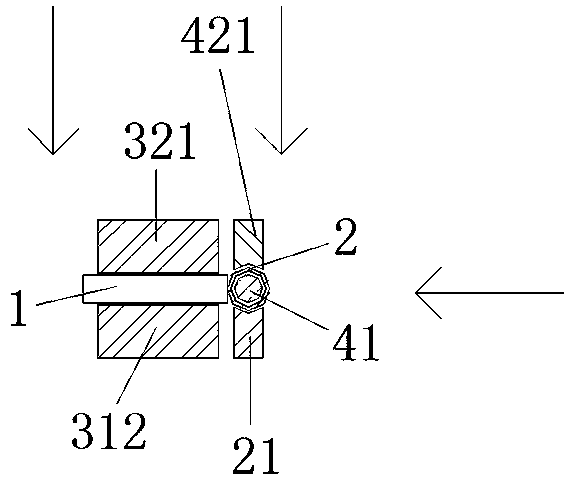

[0030] Embodiment three, refer to image 3 As shown, the hinge resistance welding process of the present invention, the hinge includes a leaf 1, and a shaft sleeve 2 assembled with the leaf 1, the shaft sleeve 2 is cut from a steel pipe, and the shaft sleeve 2 is provided with an inner hole. The leaf 1 is cut by steel strip or steel plate. The manufacture of the hinge is to weld the leaf 1 and the bushing 2 by resistance welding process. Firstly, the leaf 1 and the bushing 2 are precisely positioned and then passed It is welded by the resistance welding process, the resistance welding process is controlled by the resistance welding welding system, the resistance welding welding system includes a shaft sleeve positioning tooling system and a sheet positioning tooling system, and the sheet positioning tooling system includes a sheet reference electrode and a sheet Limit fixed electrode, shaft sleeve positioning tooling system includes shaft sleeve positioning shaft 41, shaft sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com