Bridge bearing grouting material and preparation method thereof

A technology of bridge bearings and grouting materials, which is applied in the field of building materials, can solve problems such as poor construction quality and slow development of grouting material strength, and achieve the effects of adjustable setting time, low production cost, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

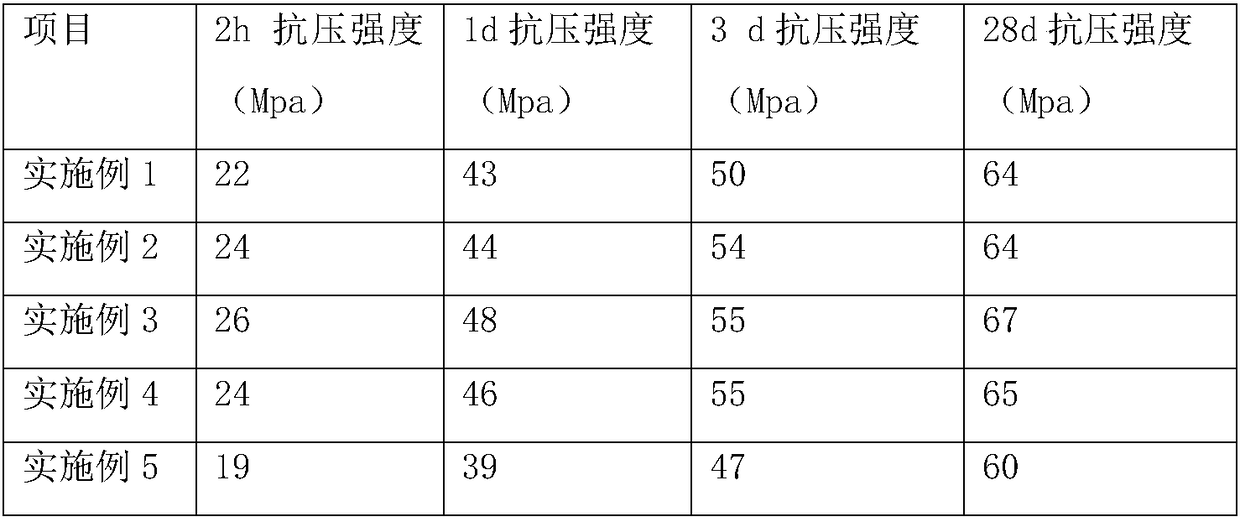

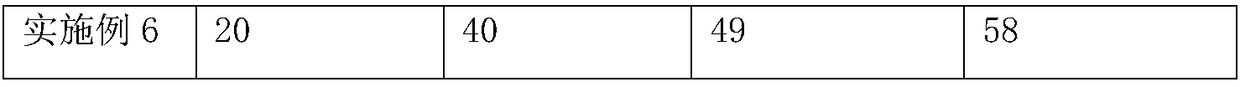

Examples

Embodiment 1

[0024] A bridge bearing grouting material, characterized in that it includes 350 parts of cementitious material, 500 parts of fine aggregate, 20 parts of expansion agent, 50 parts of fly ash, and 7 parts of admixture;

[0025] The cementitious material is a mixture of sulfoaluminate and ordinary Portland cement 42.5, and the mixing mass ratio is 5:3;

[0026] The fine aggregate is quartz sand, and the particle size of the quartz sand is 0.1-4mm;

[0027] The admixture is composed of 2 parts of water reducer and 2.5 parts of early strength agent; the water reducer is polycarboxylate water reducer, the dosage is 2.5 parts, and the water reducing rate is 30-39%.

[0028] High water reduction efficiency and better compatibility with other materials.

[0029] In this embodiment, among the quartz sand, the quartz sand with a particle size of 0.1-0.5 mm accounts for 20% of the total amount of the quartz sand; the quartz sand with a particle size of 0.5-2.5 mm accounts for 50% of the...

Embodiment 2

[0032] A bridge bearing grouting material, characterized in that it includes 500 parts of cementitious material, 800 parts of fine aggregate, 60 parts of expansion agent, 110 parts of fly ash, and 25 parts of admixture;

[0033] The cementitious material is a mixture of sulfoaluminate and ordinary Portland cement 42.5, and the mixing mass ratio is 5:1;

[0034] The fine aggregate is quartz sand, and the particle size of the quartz sand is 0.1-4mm;

[0035] The admixture is composed of 10 parts of water reducer, 6 parts of early strength agent group and 2 parts of defoamer; the water reducer is polycarboxylate water reducer, the dosage is 7 parts, and the water reducing rate is 30 to 39 %.

[0036] High water reduction efficiency and better compatibility with other materials.

[0037] In this embodiment, among the quartz sand, the quartz sand with a particle size of 0.1-0.5 mm accounts for 20% of the total amount of the quartz sand; the quartz sand with a particle size of 0.5...

Embodiment 3

[0043] A bridge bearing grouting material, characterized in that it includes 400 parts of cementitious material, 600 parts of fine aggregate, 50 parts of expansion agent, 80 parts of fly ash, and 12 parts of admixture;

[0044] The cementitious material is a mixture of sulfoaluminate and ordinary Portland cement 52.5, and the mixing mass ratio is 5:2;

[0045] The fine aggregate is quartz sand, and the particle size of the quartz sand is 0.1-4mm;

[0046] The admixture consists of 2 parts of water reducer, 3 parts of early strength agent group, 1 part of defoamer, 0.5 part of water retaining agent, and 0.5 part of retarder; the described water reducer is polycarboxylate water reducer, and the dosage is 7 parts, the water reduction rate is 30-39%.

[0047] High water reduction efficiency and better compatibility with other materials.

[0048] In this embodiment, among the quartz sand, the quartz sand with a particle size of 0.1-0.5 mm accounts for 20% of the total amount of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com