Concrete 3D printing material based on section molding and 3D printing manufacturing method

A 3D printing and manufacturing method technology, applied in the direction of manufacturing tools, additive processing, ceramic molding machines, etc., can solve the difficulties of adding steel bars, the impact and mechanism of action are not completely clear, and the uncertainty of the engineering application of concrete 3D printing manufacturing, etc. problems, to achieve the effect of ensuring printing efficiency, improving printing efficiency, and ensuring long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

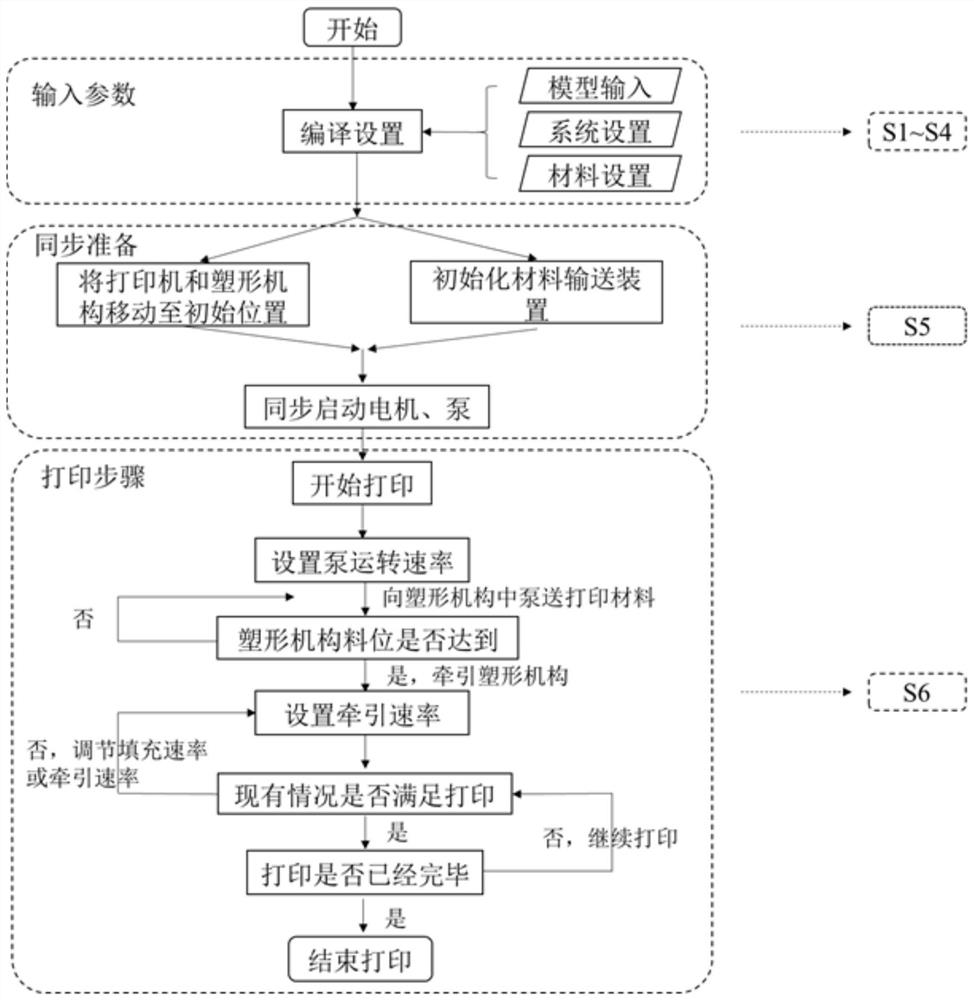

Method used

Image

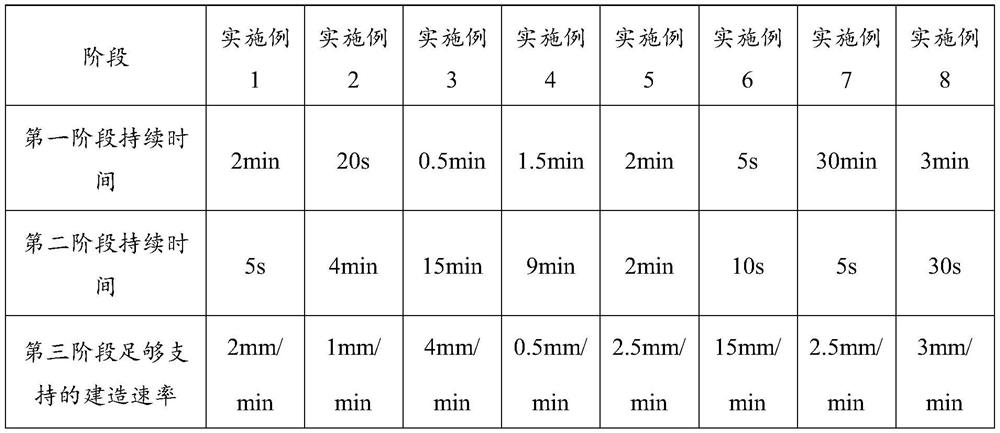

Examples

Embodiment 1

[0061] The cement-based retarding mixture of this embodiment includes aggregates, cementitious materials, fibers, a first rheology-modifying component, and water.

[0062] The aggregate in this embodiment is 0.63mm-2.36mm continuously graded quartz sand, which accounts for 90% of the total mass of the cement-based retarding mixture.

[0063] The cementitious material in this embodiment is P.O 52.5 ordinary Portland cement, and the proportion of the cementitious material in the total mass of the cement-based retarding mixture is 8%.

[0064] The fibers in this embodiment are polypropylene fibers, and the proportion of the polypropylene fibers in the total mass of the cement-based retarding mixture is 1.2%.

[0065] The first rheology-adjusting component of this embodiment includes a polycarboxylic acid-based superplasticizer and hydroxypropyl methylcellulose ether. The proportion of the first rheology-adjusting component to the total mass of the cementitious material is 10%. ...

Embodiment 2

[0070] The cement-based retarding mixture of this embodiment includes aggregates, cementitious materials, fibers, a first rheology-modifying component, and water.

[0071] The aggregate in this embodiment is 0.63mm-2.36mm continuously graded quartz sand, which accounts for 10% of the total mass of the cement-based retarding mixture.

[0072] The cementitious material in this embodiment is P.O 52.5 ordinary Portland cement, and the proportion of the cementitious material in the total mass of the cement-based retarding mixture is 70%.

[0073] The fibers in this embodiment are steel fibers, and the proportion of the steel fibers in the total mass of the cement-based retarding mixture is 3%.

[0074] The first rheology-adjusting component of this embodiment includes polycarboxylic acid-based superplasticizer and hydroxyethyl cellulose ether. The proportion of the first rheology-adjusting component to the total mass of the cementitious material is 10%.

[0075] The setting adjus...

Embodiment 3

[0079]The cement-based retarding mixture of this example includes aggregates, cementitious materials, fibers, rheology-modifying components, and water.

[0080] The aggregate in this embodiment is 0.63mm-2.36mm continuously graded quartz sand, which accounts for 50% of the total mass of the cement-based material.

[0081] The cementitious material in this embodiment is P.O 52.5 ordinary Portland cement, and the proportion of the cementitious material in the total mass of the cement-based material is 40%.

[0082] The fibers in this embodiment are polyvinyl alcohol fibers, and the proportion of the polyvinyl alcohol fibers in the total mass of the cement-based material is 2.5%.

[0083] The first rheology-adjusting component in this embodiment includes a polycarboxylic acid-based superplasticizer, hydroxypropyl methylcellulose ether and nano-modified clay. The proportion of the first rheology-adjusting component to the total mass of the cementitious material is 1.5%.

[0084]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com