High-strength low-water absorption cement base plate slurry and method for making same

A low water absorption, cement-based technology, applied in the field of building materials, can solve problems such as chipping, warping and cracking of plates, and achieve the effects of low water absorption, simplified production process, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

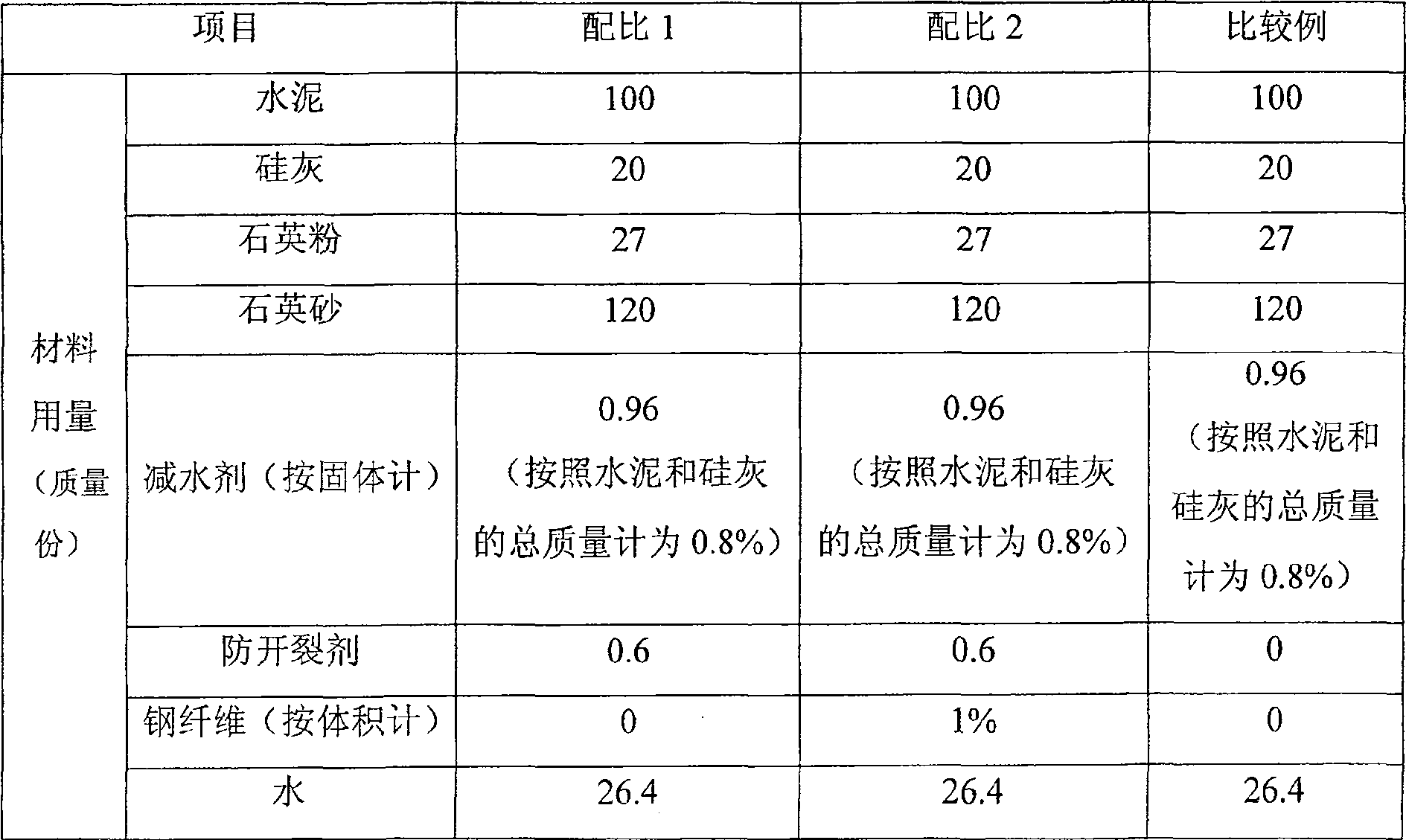

[0032] Example 1: Slurry and board prepared using ordinary Portland cement. See Table 1 for raw materials and specifications, and Table 2 for material ratios and properties.

[0033] Table 1

[0034] Material Specification or grade source cement PO 42.5 ordinary Portland cement Shanghai Seal Cement Group Silica fume EM920U Elkem International Trading Shanghai Co., Ltd. Quartz powder 320 mesh Anhui Fengyang Fengcheng Powder Material Co., Ltd. Quartz sand 30~70 mesh Anhui Fengyang Fengcheng Powder Material Co., Ltd. steel fiber Section 0.25×0.25mm, length 13mm, in line with the standard

JG / T3064-1999. Produced by Shanghai Qingpu Shangta Metal Fiber Factory Superplasticizer PC new high-efficiency water reducer for concrete; pH neutral; solid

Content 40%; Viscosity (Tu-4 cups) 40s Shanghai Aoshen Architectural Chemical Technology Co., Ltd. Anti-cracking agent Polyethylene glycol, molecular weight 1000 ...

Embodiment 2

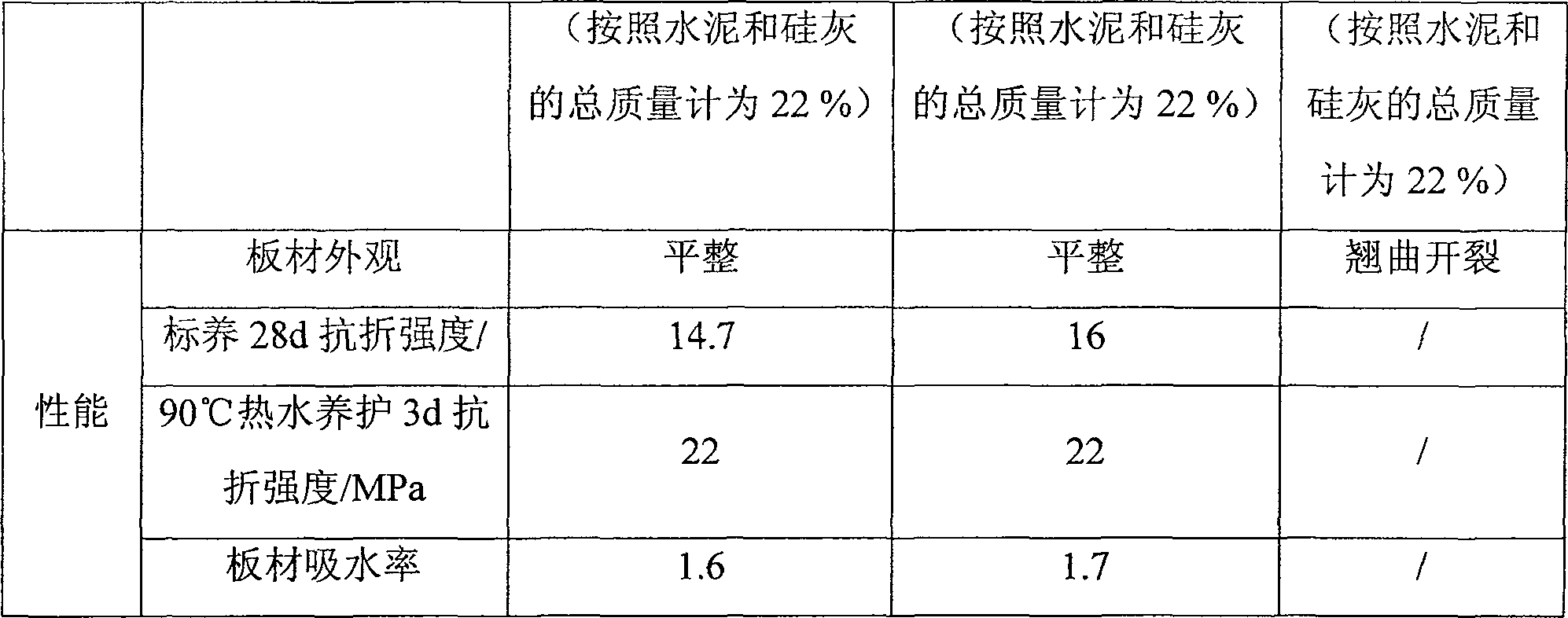

[0038] Example 2: Portland cement is used to prepare the prepared slurry and board. The specifications and manufacturers of the materials used are shown in Table 3, and the material ratio and properties are shown in Table 4.

[0039] table 3

[0040] Material Specification or grade source cement PII 52.5R Jiaxin Jingyang Cement Silica fume EM920U Elkem International Trading Shanghai Co., Ltd. Quartz powder 320 mesh Anhui Fengyang Fengcheng Powder Material Co., Ltd. yellow sand Pass 0.63mm sieve Ordinary yellow sand Superplasticizer GLENIUM SP-8CN Shanghai Master Building Materials Co., Ltd. Anti-cracking agent Polyethylene glycol, molecular weight 1600

[0041] Table 4 Slurries and boards prepared with Portland cement and their comparative examples

[0042]

[0043]

Embodiment 3

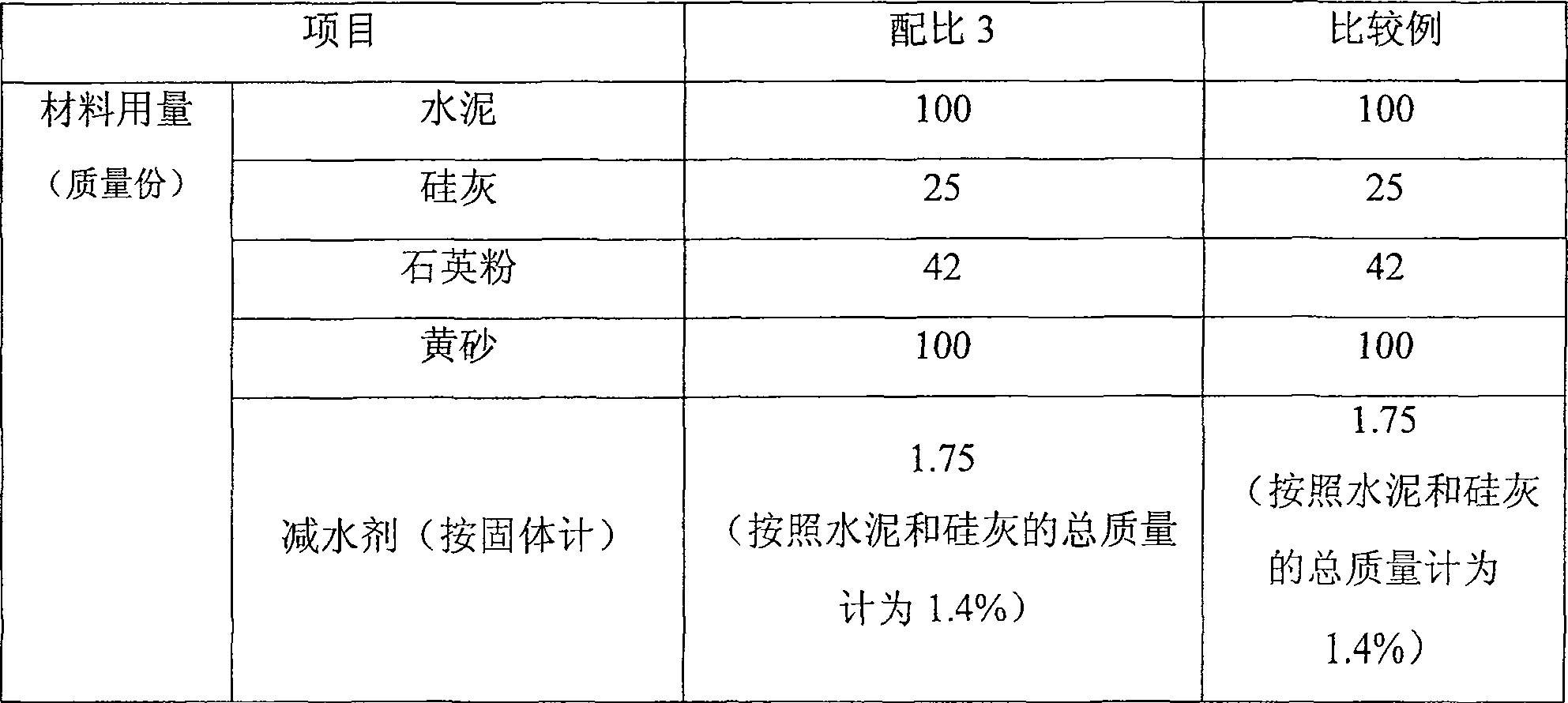

[0044] Embodiment 3: see Table 1 for raw material specifications, and see Table 5 for material proportions and properties.

[0045] Table 5 Slurries and panels prepared with ordinary Portland cement

[0046]

[0047] Known from embodiment 1-embodiment 3, according to the slurry prepared by proportioning of the present invention and preparation process, its flow extension (utilize the truncated cone circular mold test of jumping table fluidity, but do not vibrate) surpasses 250mm, has automatic Compact performance, no need to vibrate when forming the product. The product is demoulded under normal temperature and humidity conditions for 1 day, then immersed in water at room temperature for 28 days, and the flexural strength of the sheet exceeds 15MPa; if it is cured with 90°C steam for 3 days, the flexural strength of the sheet exceeds 20MPa; it is a high-strength material that is easy to form. In addition, the obtained plate has a water absorption rate of less than 2%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com