Self-compacting backfill material, and preparation method and application thereof

A technology of self-compacting and cementitious materials, which is applied in filling, construction, infrastructure engineering, etc., can solve problems such as difficult compaction, difficult backfilling, and difficult filling, so as to ensure strength and stability and reduce pollution hazards , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

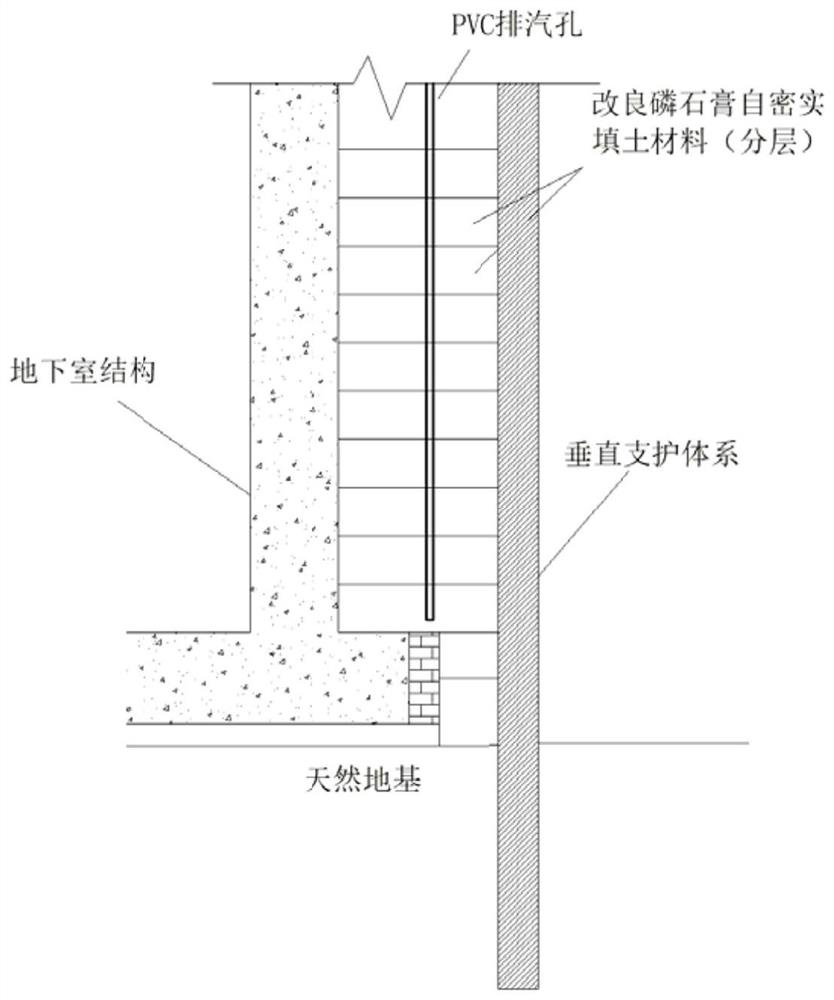

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

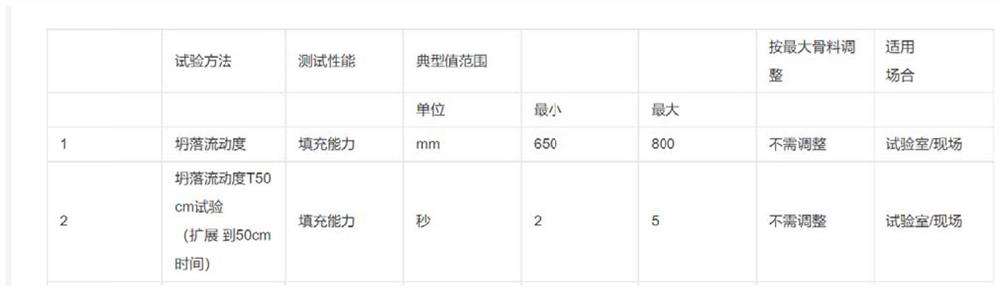

[0020] The invention provides a self-compacting backfill material. The raw materials include industrial phosphogypsum, quicklime, bentonite, sieved soil, ordinary Portland cement powder, mineral powder and water. The self-compact backfill material can be obtained after mixing the above-mentioned raw materials in a certain proportion. ,

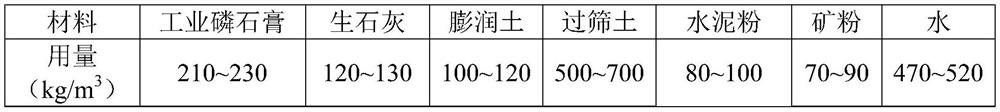

[0021] Preferably, the weight proportion between each raw material is:

[0022]

[0023] Preferably, the industrial phosphogypsum is industrial waste phosphogypsum, which is used to improve the workability of self-compacting backfill.

[0024] Preferably, quicklime is used to eliminate the harm caused by strong acidity such as fluoride ions and free sulfate radicals in industrial phosphogypsum, improve the later strength of self-compacting backfill materials, and slowly absorb the moisture in self-compact b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com