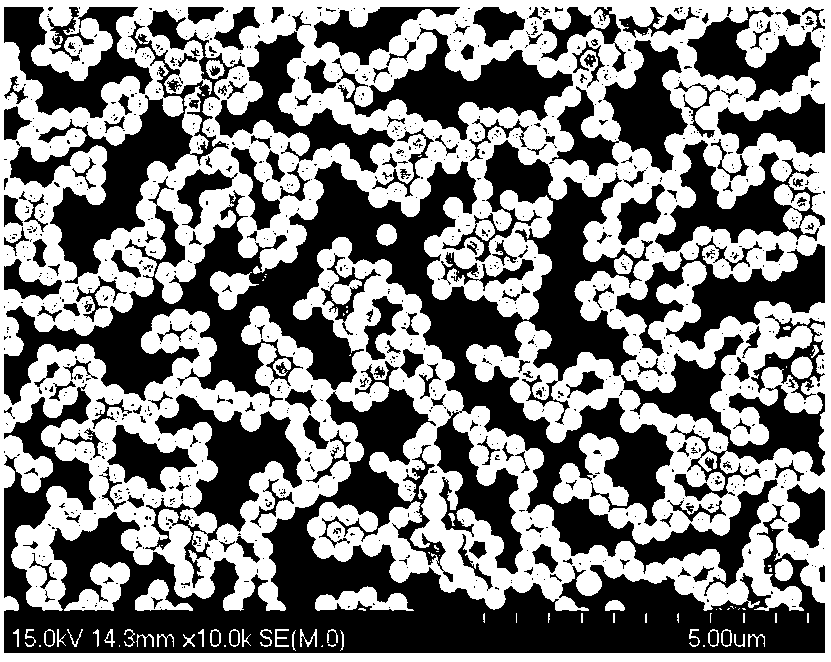

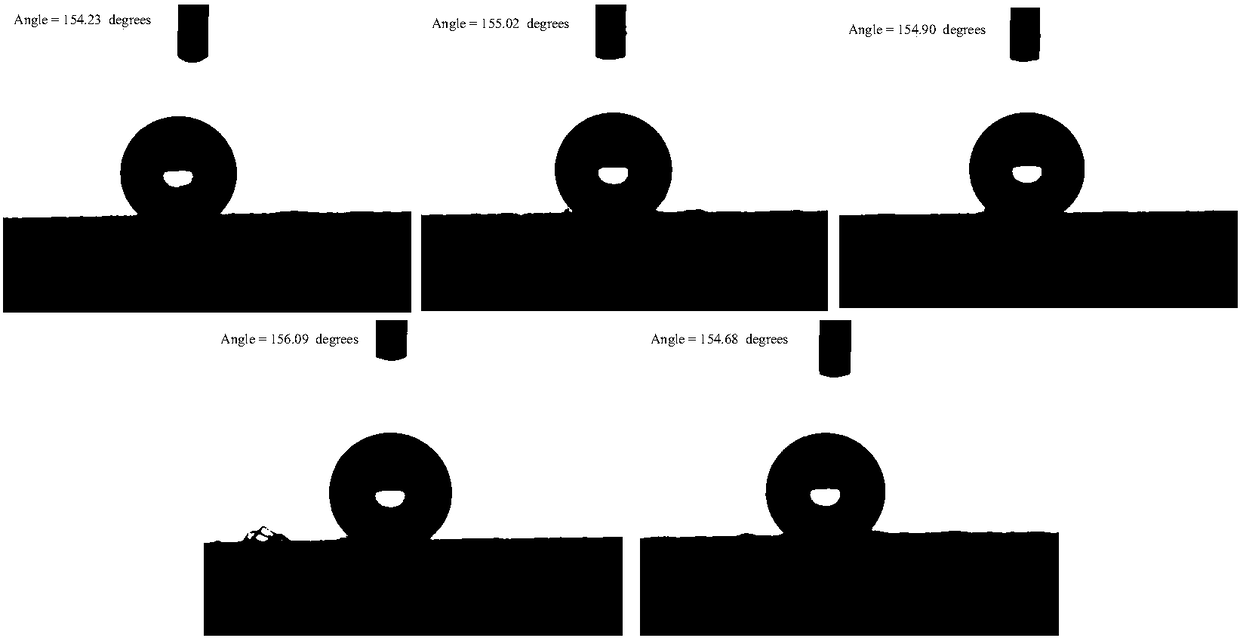

Method for preparing superhydrophobic surface of silicon-based micro-nano two-level structure

A super-hydrophobic surface and secondary structure technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of inaccurate control of super-hydrophobic structure and low water collection rate, and achieve excellent super-hydrophobic performance, Good stability and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention once.

[0049] A method for preparing a silicon-based micro-nano secondary structure superhydrophobic surface, comprising the following steps:

[0050] (1) Preparation of silicon-based superhydrophobic layer microstructure. Specifically include the following steps:

[0051] a. Thermal oxidation

[0052] Deposition on the front side (polished side) of silicon wafers SiO 2 , as a mask material for KOH solution wet etching of silicon, it is found by looking up Table 1-2 that SiO 2 The corrosion rate in a 40% KOH solution at 50°C is 30.3nm / H, while the corrosion rate of Si in a 40% KOH solution at 50°C is 10.5μm / H, and the required corrosion depth does not exceed 10 µm, therefore, SiO 2 It is sufficient as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com