A rotating vane-meshed type volume changing mechanism

A meshing and rotating plate technology, applied in the direction of rotary piston machinery, rotary piston engine, rotary piston pump, etc., can solve the problems of maximum thrust limit, large vibration in reciprocating motion, high manufacturing precision, and achieve small vibration and noise, The effect of large reaction force and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

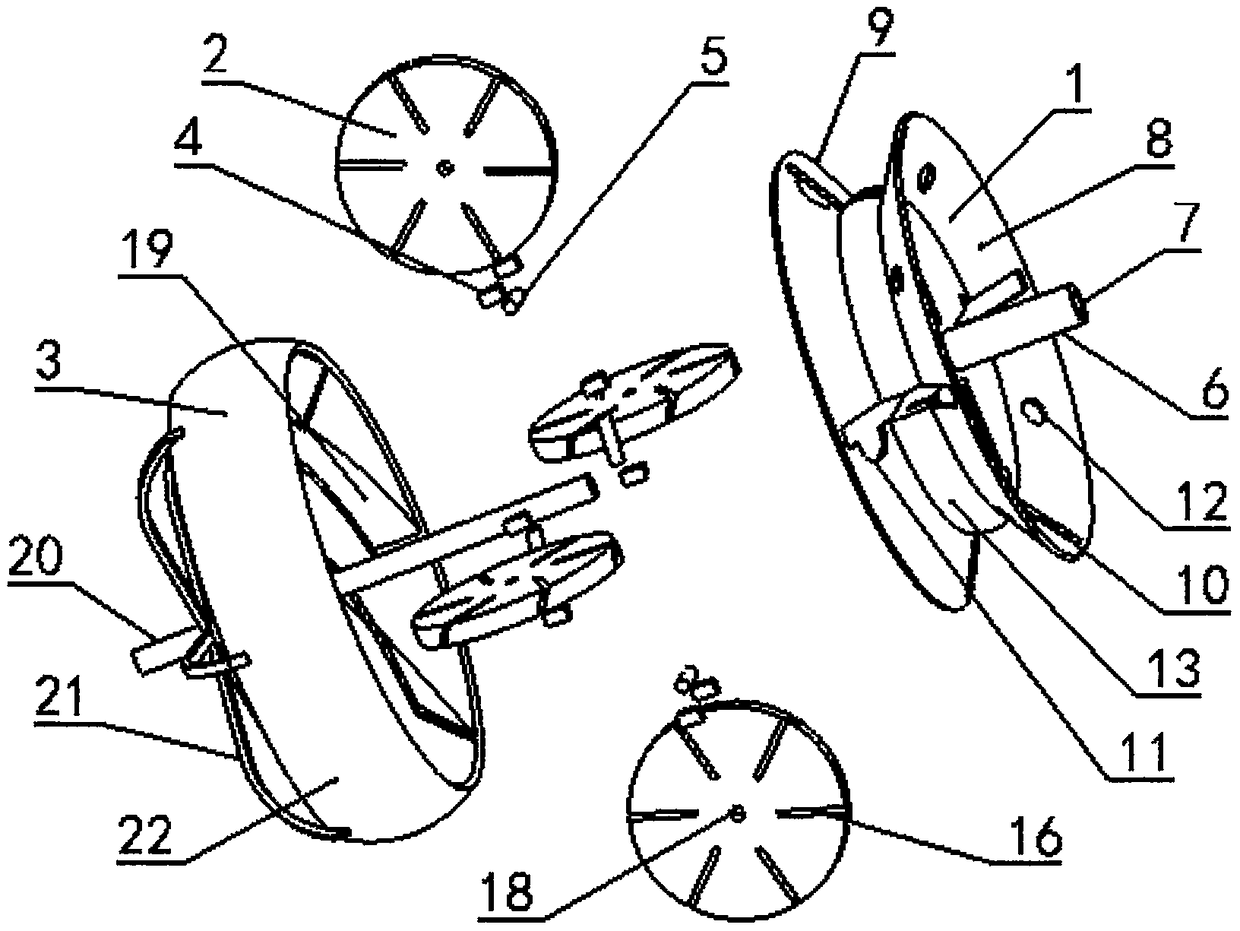

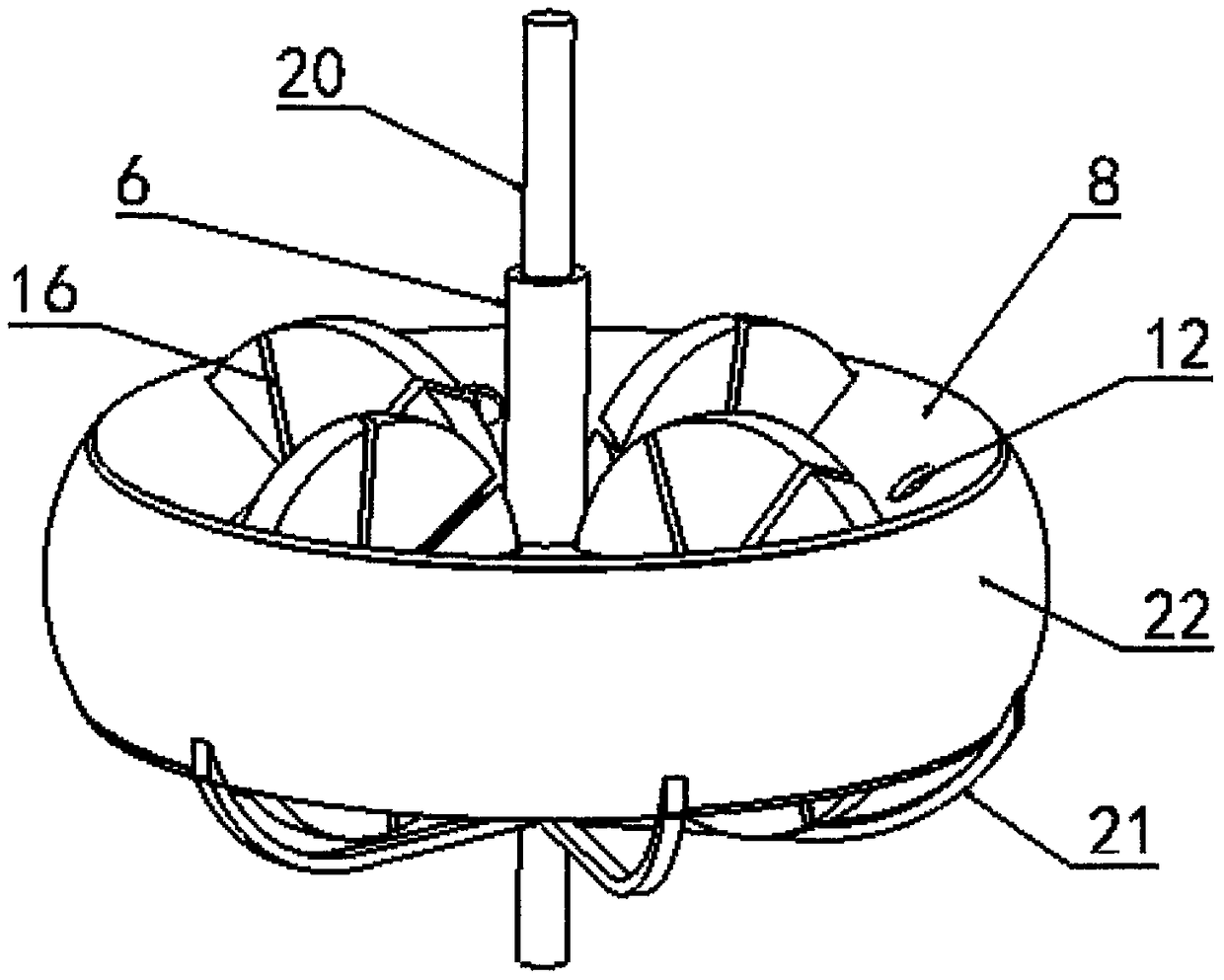

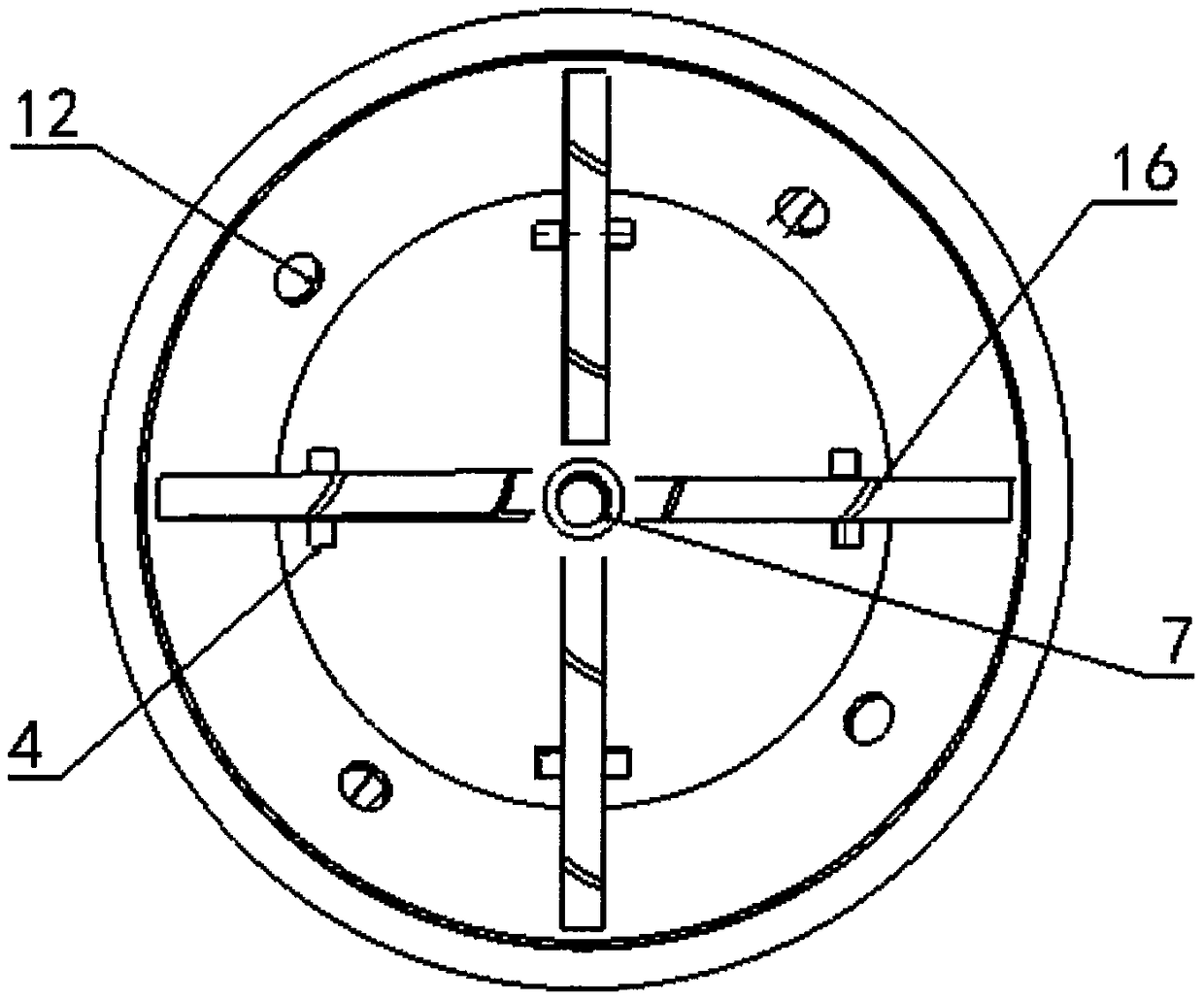

[0073] 1. Overall structure and appearance

[0074] The rotating vane engagement type displacement mechanism of this embodiment is a structure suitable for vacuum machines and compressors. Through the engagement of the rotating vane 19 and the rotating plate 2, air inlet holes are respectively provided at the appropriate positions of the upper end cover 8 and the lower end cover 9. 12 and exhaust hole 11, in order to realize vacuuming or compressing the target equipment. Figure 1 to Figure 18 The vacuum machine is mainly used as an example for illustration. If it is to be converted into a compressor, the fixed shaft 6 needs to be arranged on the other side of the first intermediate fixed body 1, and the connecting rod 21 is arranged on the other side of the first peripheral rotating body 3, so that the One side of the air hole 12 is driven by the connecting rod 21 to rotate the rotating shell 22, and one side of the exhaust hole 11 is fixed and connected to the target equipme...

Embodiment 2

[0088] 1. Overall structure and appearance

[0089] The rotary vane meshing variable displacement mechanism of this embodiment is a structure suitable for a rotary engine. Through the engagement of the rotary vane 19 and the rotary plate 2, some through holes and rotary grooves are arranged on the rotary shell 22, and the second intermediate fixed body 27 Some through holes, baffles, air holes and igniters are arranged on the top to realize the four processes of suction, compression, ignition and exhaust, so as to promote the continuous rotation of the variable capacity mechanism. For the convenience of describing this embodiment clearly, the side including the fixed shaft 6 is marked as the front side, and the opposite side is marked as the back side.

[0090] Such as Figure 19 As shown, the general structure of the variable capacity mechanism of this embodiment is similar to that of Embodiment 1, mainly because the intermediate fixed body and the peripheral rotating body a...

Embodiment 3

[0115] 1. Overall structure and appearance

[0116] The rotating vane meshing variable displacement mechanism of this embodiment is a structure suitable for fluid dynamic machinery, similar to the ducted fan propeller, but the meshing rotation of the rotating vane and the rotating plate can transmit the rotational kinetic energy of the machine to the fluid to a greater extent. Compared with other fluid power machines, under the same rotation speed, the fluid can obtain a greater speed of movement perpendicular to the rotation plane. Applying this mechanism to the paddle part of ships, helicopters, etc., can obtain greater thrust than ordinary paddles.

[0117] Such as Figure 42 As shown, the general structure of the variable capacity mechanism of this embodiment is similar to that of Embodiment 1, mainly because of some differences in the middle fixing body, so it is named as the third middle fixing body 52 . After being assembled similarly to Embodiment 1, the upper plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com