Drying equipment for packaging boxes

A technology for drying equipment and packaging boxes, which is applied in drying, drying machines, lighting and heating equipment, etc. It can solve the problems of damage to the inner wall of the equipment, softening of products, and uneven drying effect, so as to avoid moisture in sea transportation and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below.

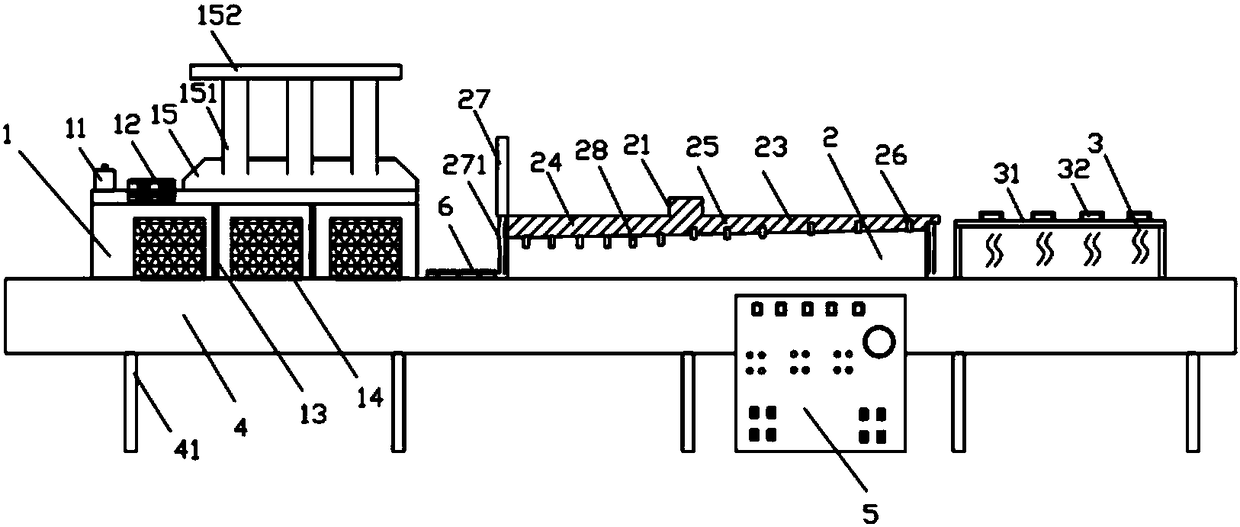

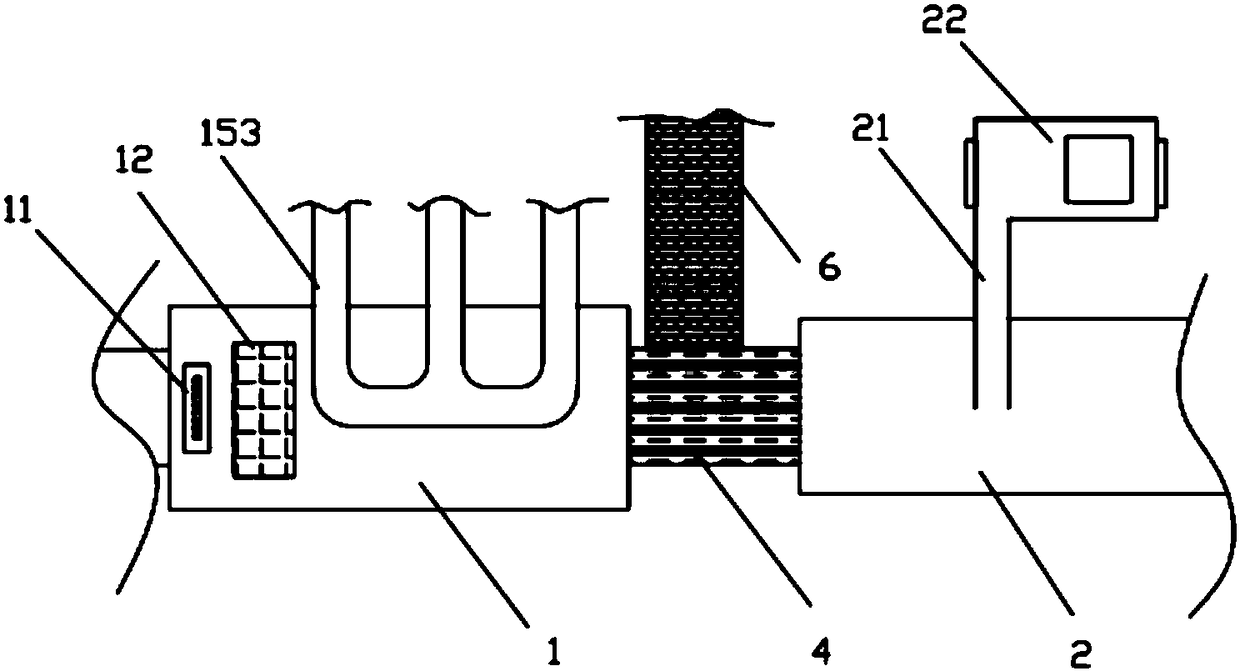

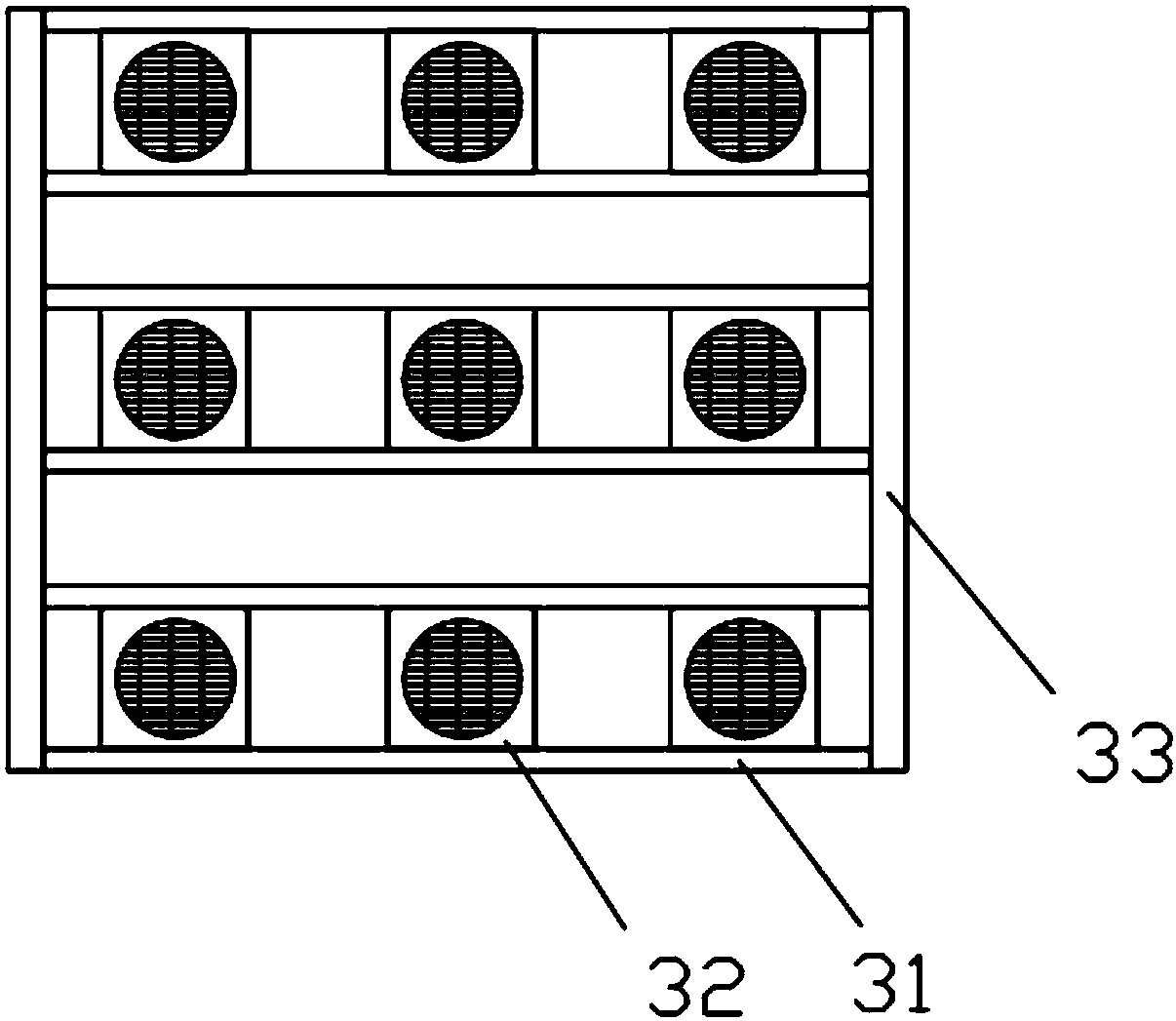

[0027] Such as Figure 1-2 As shown, the microwave device 1 is installed at the leftmost end of the workbench 4, the heat drying device is located in the middle of the workbench 4, the cooling section 3 is located at the right end of the workbench, and the workbench 4 is equipped with a conveyor belt, and the left side of the conveyor belt is used for drying the packaging boxes. The entrance, the right side is the exit, the packaging box can choose to enter from the microwave device 1 according to different materials, then pass through the heating device 2, heat dissipation section 3, and finally collect, or pass through the transportation between the heating device 2 and the heat dissipation section 3 The belt 6 directly enters the drying device 2. Because some packaging boxes only cover a large number of metal sheets on the cover body, and the box body is not embedded with metal, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com