Dryer

A dryer and fan technology, applied in dryers, drying, progressive dryers, etc., can solve the problems of high consumption of hot steam, high power consumption, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

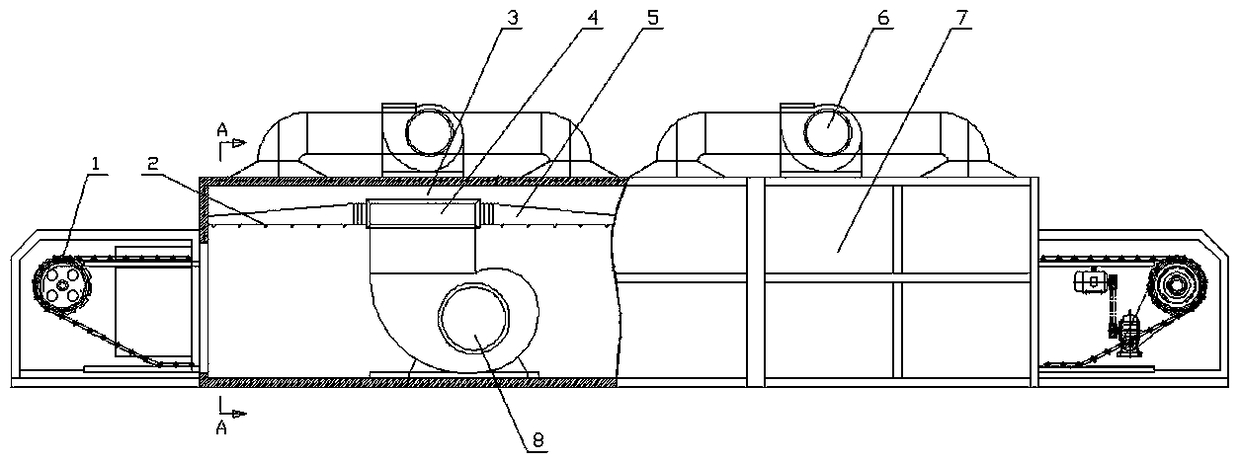

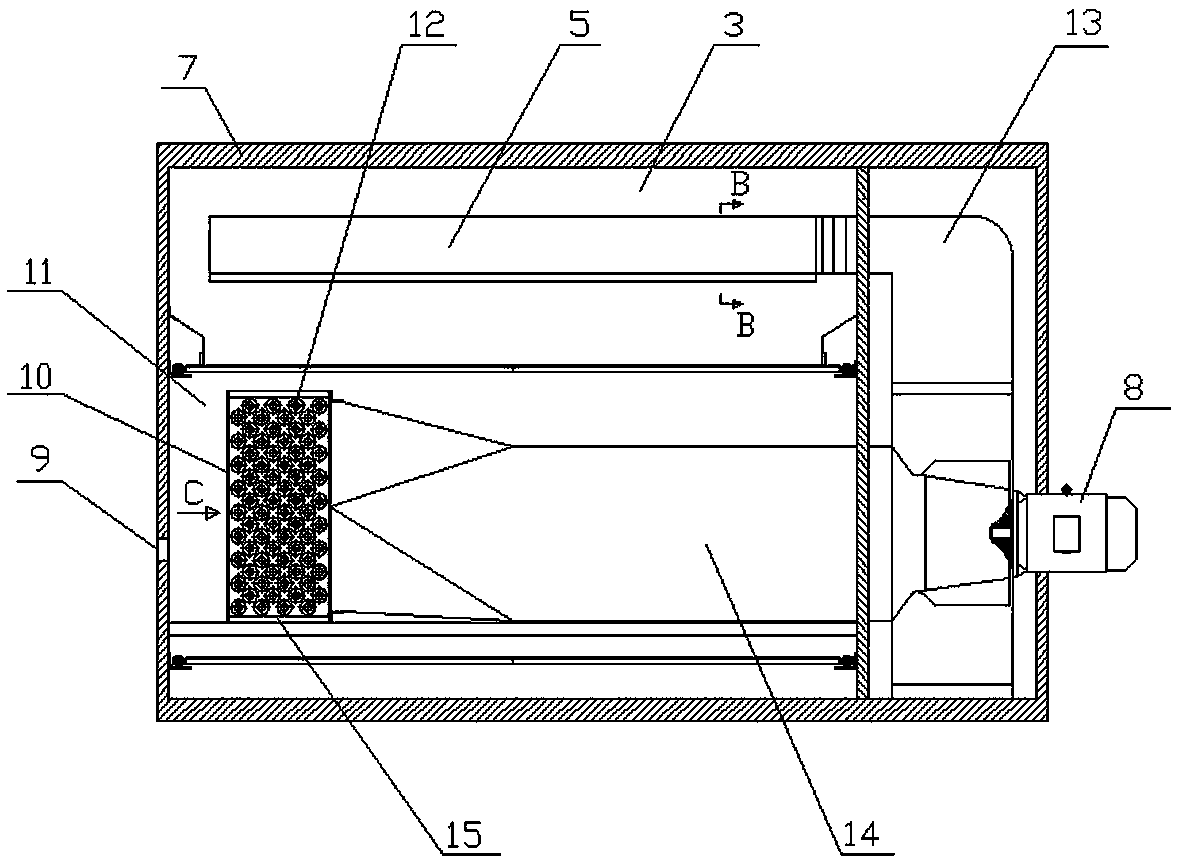

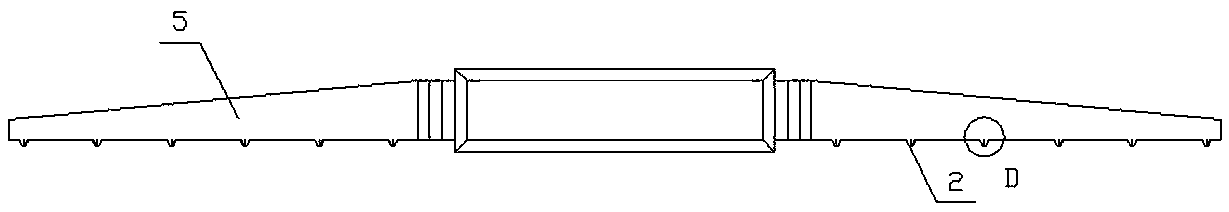

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the dryer of the present invention includes a rectangular parallelepiped box 7, which is arranged horizontally. The box body 7 is formed by connecting no less than two unit box bodies, and the specific number depends on the need. For simplicity, only two unit boxes are drawn in this embodiment. A belt conveyor 1 is arranged inside the box body 7 , and both ends of the belt conveyor 1 protrude outside the two ends of the box body 7 . A fan 8 is installed on the outside of each unit box, and the fans 8 are all installed on the outside of the box wall on the same side of the unit box. The upper part of the inner cavity of each unit box is provided with an air equalizing box 5, which is flat, and the size of the top plate and the bottom plate are adapted to the horizontal profile of the inner cavity of the unit box, and the distance between the two ends of the top plate and the bottom plate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com