Vertical shaft steel wire rope guide sliding sleeve wear amount detecting device and detecting method thereof

A wire rope tank channel and wear detection technology, which is applied to measuring devices, electromagnetic measuring devices, electrical devices, etc., can solve the problems of sensitivity to environmental factors, high price, inconvenient installation, etc., and achieves good stability, low cost, and easy installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

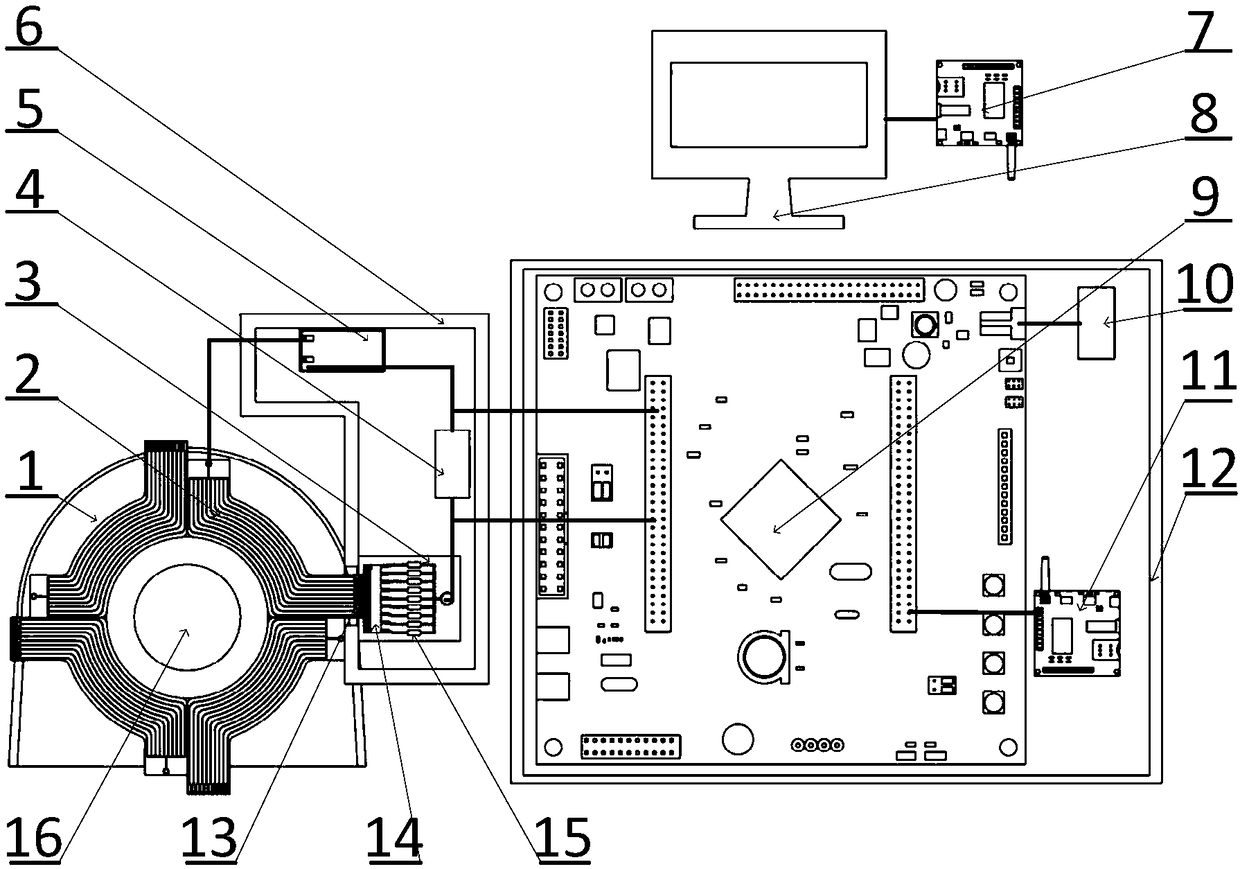

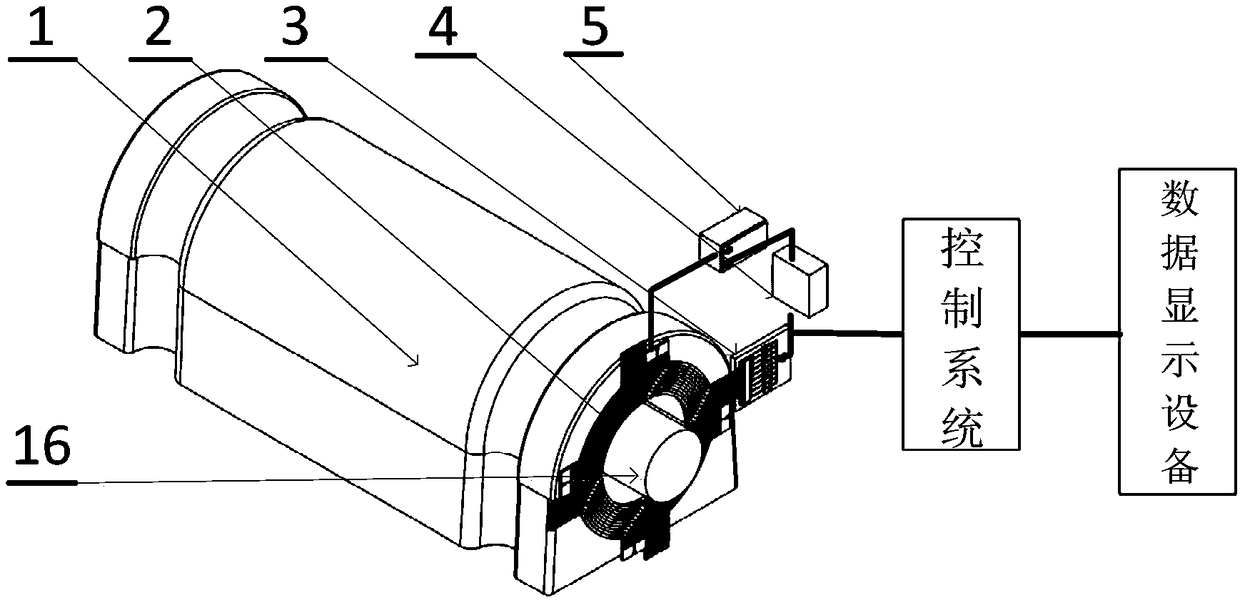

[0038] In order to make the object, technical solution and optimization points of the present invention clearer and clearer, the invention provides a method and device for detecting the wear amount of the shaft steel wire rope tankway sliding sleeve based on FPC. invention, but does not thereby limit the invention to the scope of the described embodiments.

[0039] The invention discloses a detection device for the amount of wear of a shaft steel wire rope tankway sliding sleeve, which comprises a plurality of FPC cable units, a plurality of voltage detection circuit units, a control system and data display equipment.

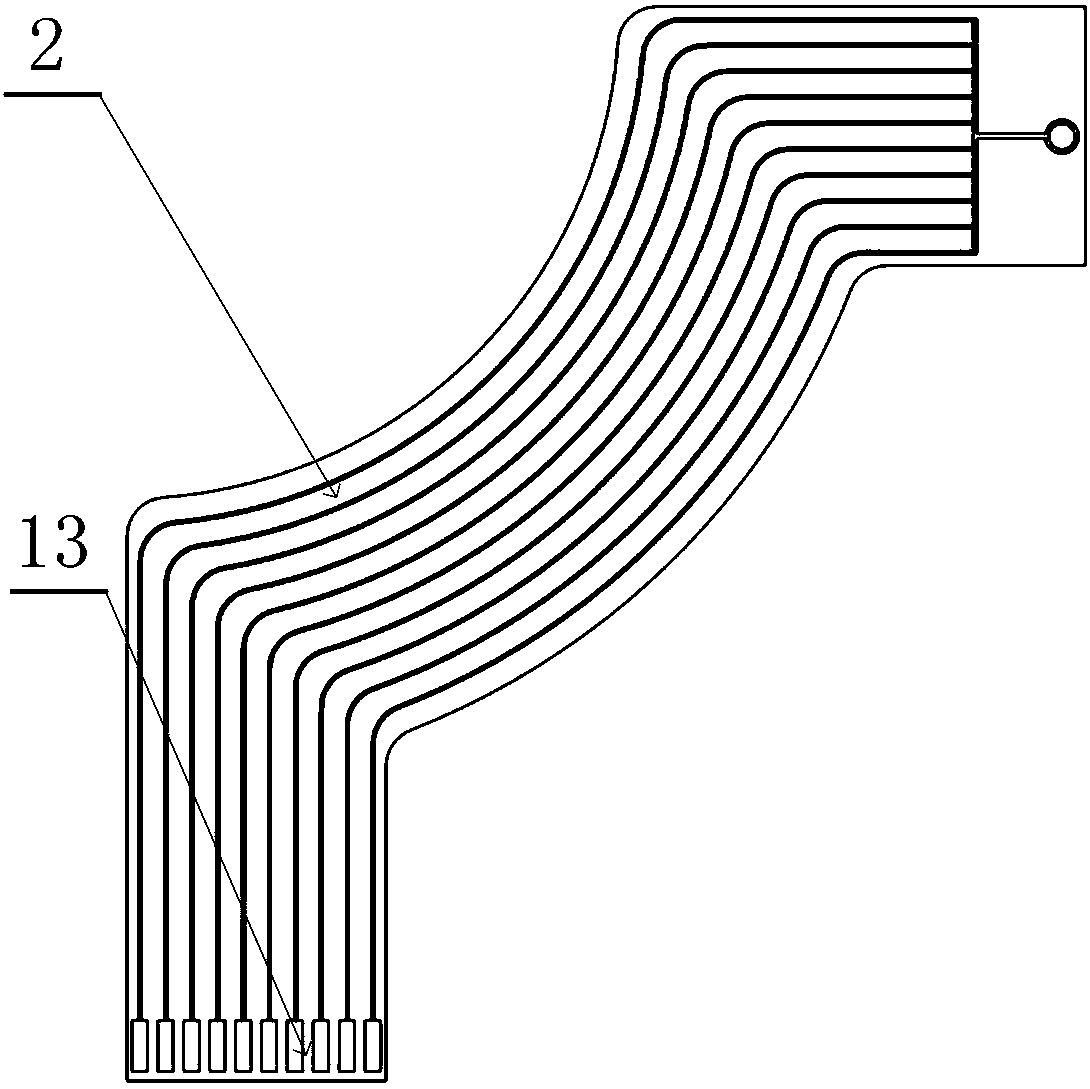

[0040] The two ends of the vertical well steel wire rope tank way sliding sleeve are respectively provided with a plurality of FPC cable units, and the multiple FPC cable units are pasted to the end surface of the vertical well steel wire rope tank way sliding sleeve around the outer circumference of the steel wire rope hole to form a closure; each FPC row The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com